Forklift-Pedestrian Accident Prevention: Enhancing Safety Through Advanced Forklift Safety Systems

Forklifts are essential in dynamic situations like warehouses and manufacturing facilities, but they may pose substantial dangers, especially when dealing with pedestrians. According to OSHA statistics, forklift accidents cause a significant number of severe injuries and fatalities each year. Many of these accidents included pedestrians, emphasizing the urgent need for improved safety standards.

This article focuses on the critical role that advanced forklift safety systems play in mitigating these risks, focusing on technological innovations that prevent forklift-pedestrian collisions.

Understanding the Risks of Forklift-Pedestrian Accidents

Forklift operations within the bustling confines of warehouses and manufacturing facilities present inherent risks, particularly for pedestrian safety. According to OSHA, each year, approximately 100 workers lose their lives, and an additional 20,000 sustain severe injuries in incidents involving forklifts. The common factor in many of these accidents is the interaction between forklifts and pedestrians- individuals who may be in close proximity to active forklift operations.

The nature of these environments often leads to compromised visibility and auditory perception, making it difficult for operators to notice pedestrians and vice versa. The resulting accidents frequently occur when safety measures are either inadequate or improperly enforced. Typical incidents involve pedestrians being struck or run over by forklifts, which may be maneuvering with limited sightlines or at unsafe speeds. Pedestrians are also at risk of being injured by materials that may fall from a forklift during operations.

These accidents underscore the critical need for stringent safety protocols and measures in areas where forklifts and pedestrians are likely to intersect.

Advanced Forklift-Pedestrian Accident Prevention Systems

Various advanced safety technologies have been developed to minimize these hazards. These systems are designed to enhance the operator's ability to detect and avoid pedestrians, improve control over the vehicle, and thereby increase safety in the workplace.

As forklift operations become more complex and warehouse traffic increases, the effectiveness of these technologies depends not only on detection capability but also on how well they are integrated into overall safety processes. Real-time alerts, intelligent proximity detection, and structured safety protocols must work together to create a truly preventive environment. To explore a broader framework for improving interaction safety between forklifts and pedestrians, you can also read our detailed guide: A Guide to Forklift-Pedestrian Safety.

Proximity Sensors and Alarms

Proximity sensors are indispensable in the arsenal of modern forklift safety systems, providing essential protection against collisions. These sensors are engineered to detect static and dynamic obstacles in the forklift’s operational area, including pedestrians.

Here’s how they contribute to workplace safety:

| Features | How It Works | For Operators | For Pedestrians | How Trio Mobil Helps |

|---|---|---|---|---|

| Detection and Alerts | Proximity sensors identify obstacles in the forklift’s path and trigger auditory and visual alarms. | Alerts operators to immediate hazards, allowing for timely stopping or maneuvering. | Alerts pedestrians to the presence of forklifts, enhancing situational awareness. | Trio Mobil’s advanced detection systems use UWB technology and AI to provide precise and timely alerts. |

| Dual-Purpose Alarms | Alarms sound to inform both the operator and nearby pedestrians of potential hazards. | Provides crucial alerts to prevent collisions. | Critical alerts notify of approaching forklifts, especially in noisy environments. | Trio Mobil’s integrated alarm systems provide simultaneous alerts to both operators and pedestrians. |

| Enhanced Situational Awareness | Sensors augment the operator's view of their surroundings, especially in blind spots or congested areas. | Increases awareness of environmental obstacles, improving safety in tight spaces. | Warns of close proximity to forklifts, helping maintain a safe distance. | Trio Mobil’s situational awareness solutions enhance visibility in blind spots and congested areas, using AI-powered cameras and sensors to provide real-time environmental data to operators. |

| Technological Advancements | Incorporates features like directional sensing and distance estimation for precise warnings. | Enhances decision-making with accurate information about obstacle location and distance. | Provides more reliable and precise warnings to avoid accidental proximity to forklifts. | Trio Mobil incorporates cutting-edge technology, such as Mobil AI, to deliver accurate and reliable warnings. |

| Safety Culture Promotion | The use of advanced sensors promotes a safety-first approach in workplace operations. | Encourages operators to remain vigilant and adhere to safety protocols. | Builds trust in safety measures, reducing anxiety about moving forklifts. | Trio Mobil’s comprehensive safety solutions foster a culture of safety by providing reliable and advanced technologies. |

Speed Control Technologies

Speed control technologies in forklifts are designed to automatically adjust the vehicle's speed based on the specific areas within a facility. These systems utilize advanced technologies such to monitor the forklift's location and dynamically modify its speed to maintain safe operation in areas with high pedestrian traffic.

Here’s how they contribute to workplace safety:

| Features | How It Works | For Operators | For Pedestrians | How Trio Mobil Helps |

|---|---|---|---|---|

| Automatic Speed Adjustment | Speed control systems use UWB detection and IoT connectivity to detect the forklift’s position and automatically adjust speed. | Promotes forklift safety by maintaining appropriate speeds in various zones. | Enhances safety by reducing the risk of high-speed encounters with forklifts. | Trio Mobil’s speed adjustment systems leverage UWB technology and IoT infrastructure to help maintain forklifts at controlled speeds. |

| Designated Safety Zones | The system limits the forklift's speed to a safe threshold in areas with high pedestrian traffic. | Helps operators maintain safe speeds, reducing cognitive load during operations. | Provides a safer walking environment by minimizing the risk of accidents. | Trio Mobil’s designated safety zones use advanced technology to enforce safe speed limits in high-traffic areas. |

| Technology Integration | Integration of UWB and AI to manage speed settings based on real-time location data. | Facilitates compliance with site-specific safety protocols. | Increases confidence in forklift operations' adherence to safety standards. | Trio Mobil’s integrated technology solutions combine UWB and AI to manage forklift speed control logic. |

| Accident Risk Reduction | Enforced speed limits within the facility decrease the likelihood and severity of accidents. | Supports a safer operational environment, decreasing potential for severe accidents. | Assures a lower risk of accidents, contributing to a safer workplace atmosphere. | Trio Mobil’s enforced speed limits and real-time monitoring significantly reduce the risk and severity of accidents. |

Camera and Vision Systems

Camera and vision systems are instrumental in broadening forklift operators' fields of view, particularly in areas with limited visibility. By integrating cameras, operators gain a live feed of otherwise hidden areas, drastically reducing blind spots.

Here’s how they contribute to workplace safety:

| Features | How It Works | For Operators | For Pedestrians | How Trio Mobil Helps |

|---|---|---|---|---|

| Expanded Field of View | Cameras installed on forklifts provide live feeds from blind spots and other obscured areas. | Enhances the operator's ability to see around and behind the forklift, reducing blind spot accidents. | Increases their safety by reducing the likelihood of unseen forklift movements. | Trio Mobil’s advanced AI camera systems provide operators with live feeds from blind spots, significantly enhancing their field of view and reducing the risk of accidents. |

| Real-Time Visual Aids | Real-time camera feeds help operators continuously monitor the environment around the forklift. | Assists in safe maneuvering and precise handling of the forklift. | Provides an added layer of safety as operators are more aware of pedestrian movements. | Trio Mobil’s real-time visual aids provide operators with continuous awareness of their surroundings. |

Integration of IoT and AI in Forklift Safety

Incorporating the Internet of Things (IoT) and artificial intelligence (AI) into forklift operations represents a revolutionary shift toward enhancing workplace safety. These technologies facilitate a more data-driven approach to managing forklift activities, ultimately aiming to mitigate the risks associated with forklift operations.

- IoT Devices on Forklifts: IoT devices installed on forklifts continuously collect detailed data on every aspect of forklift operation, from speed and route patterns to proximity interactions with obstacles or pedestrians. This data accumulation is crucial as it provides a comprehensive overview of the forklift's daily operations and environments.

- Data Analysis for Pattern Identification: Using advanced data analytics, the information gathered by IoT devices is meticulously analyzed to detect consistent patterns or anomalies in forklift operations. For instance, Trio Mobil’s solutions can track trends such as frequent sudden stops or near-miss incidents, which might indicate high-risk areas within a facility or potential issues with forklift operation protocols.

- AI-Powered Predictive Safety: The real power of integrating AI lies in utilising the analyzed data to forecast potential safety hazards. AI algorithms can predict hazardous scenarios by correlating specific operational patterns with previously identified risk factors. This capability enables forklift operators and facility managers to receive early warnings about possible dangers, allowing them to take preemptive actions to avoid accidents.

- Implementing Preemptive Measures: AI provides actionable insights, which facilities can use to implement targeted safety measures. For example, if AI identifies a particular intersection within a warehouse as a high-risk area for pedestrian encounters, additional safety protocols can be introduced. These might include enhanced signage, adjusted forklift speed limits, or even redesigning traffic flow to minimize interaction between forklifts and pedestrians.

- Trio Mobil's Real-Time Monitoring Solutions: Leveraging Trio Mobil's IoT and AI solutions, companies can benefit from real-time monitoring and decision-making support systems. These systems not only alert operators of immediate dangers but also assist in long-term safety planning by providing data-driven insights into the effectiveness of current safety measures.

While IoT and AI significantly enhance predictive and real-time safety capabilities, their effectiveness increases when integrated into a broader collision prevention framework. A structured approach that combines sensor technologies, zone control systems, and intelligent alert mechanisms ensures a more comprehensive risk mitigation strategy. To better understand how these technologies function within a complete prevention ecosystem, you can also explore our detailed guide: Everything About Forklift Collision Avoidance Systems.

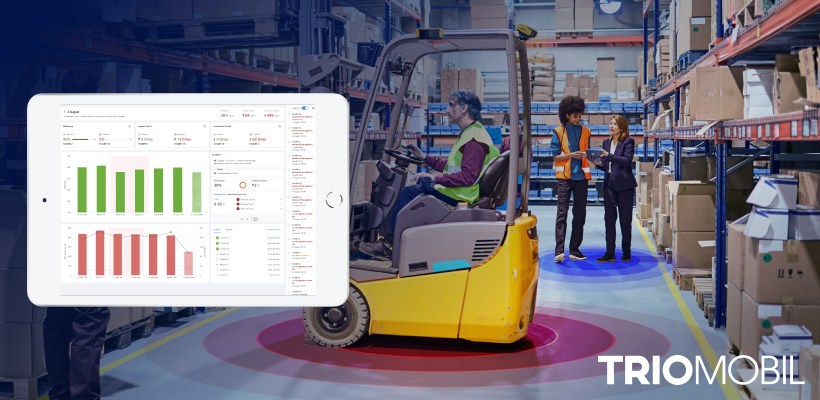

Forklift-Pedestrian Accident Prevention with Trio Mobil's Forklift Safety System

As we continue to explore and expand upon the capabilities of modern technology to improve workplace safety, Trio Mobil's Forklift Safety System stands out as a pioneering solution in preventing forklift-pedestrian accidents. By integrating advanced safety features such as proximity sensors, speed control technologies, and AI camera systems, Trio Mobil's solutions actively diminish the risk factors associated with forklift operations. These systems maintain forklifts within safe parameters, automatically adjusting behavior based on real-time environmental feedback, which protects the operators and significantly enhances the safety of pedestrians in the vicinity.

Incorporating IoT and Trio Mobil's TRUE AI into these systems elevates the effectiveness of preventative measures. This integration allows for seamless analysis of operational data, leading to predictive safety measures that can foresee and mitigate potential accidents before they occur. By offering such comprehensive safety mechanisms, Trio Mobil's Forklift Safety System exemplifies the industry's shift towards a more proactive approach to accident prevention.

For more detailed information about our cutting-edge, modular, plug-and-play solutions, browse our website or request a demo to see how our forklift safety system works.

Disclaimer: Trio Mobil solutions are operator-assist aids. They do not replace safe working practices or prevent all incidents. Performance depends on operating conditions and configuration; see product documentation.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!