How Layered AI + UWB Systems Improve Forklift Safety at Scale

Safety expectations in industrial environments are shifting. Forklifts move fast, materials change routes, and pedestrian mobility increases as operations scale. Traditional methods alone are often not enough to maintain the level of situational awareness required in high-paced logistics and manufacturing environments.

Modern safety strategies are now focusing on earlier visibility, real-time detection, and connected insights. Technologies like Ultra-Wideband proximity sensing, AI-powered detection models, and integrated layered systems are shaping the next phase of forklift safety maturity.

This transformation continues to grow as organizations look for practical ways to support their teams with more awareness and better operational understanding.

This article explores how forklift safety has evolved from reactive controls to proactive, data-driven strategies by combining UWB proximity sensing, AI-based detection, and integrated AI+UWB architectures.

Evolving Safety Demands in Industrial Operations

Industrial safety today is shaped by increasing operational density and faster material flows. As forklifts, vehicles, and pedestrians interact within shared spaces, the margin for delayed awareness becomes smaller. Improving safety outcomes depends on gaining earlier visibility into movement, proximity, and interaction patterns so organizations can better understand risk conditions and strengthen everyday operational decision-making.

Growing Operational Complexity

Material handling environments operate under constant movement. Forklifts, warehouse vehicles, and pedestrians share the same pathways where visibility can be limited. Operational tempo continues to rise as production demand increases.

The Risk Environment in Material Handling

Forklift and pedestrian interaction remains one of the highest-risk operational areas in warehouses and industrial plants. Blind corners, dynamic routes, limited line of sight, and unpredictable changes in proximity can create hazardous situations.

Why Proactive Detection Matters

Proactive monitoring supports earlier awareness. The goal is not only reacting to risk but gaining visibility into behaviors and patterns that could lead to unsafe interaction moments. Technologies that support real-time insight help teams make timely adjustments and operate with greater confidence.

UWB Based Forklift Safety Solutions

UWB based forklift safety solutions focus on improving awareness in environments where distance and timing matter most. By providing precise proximity information between forklifts, pedestrians, and defined zones, UWB technology supports earlier recognition of interaction risks. This approach helps organizations strengthen safety practices by adding a reliable spatial layer to daily material handling operations without relying on visual conditions alone.

What UWB Technology Means in Industrial Safety

Ultra Wideband is a short-range wireless communication technology designed for precise spatial positioning. In forklift safety, UWB proximity systems enable accurate detection of interactions between moving assets and pedestrians.

Strengths of UWB Systems

Ultra-Wideband (UWB) technology has emerged as a key enabler in forklift and pedestrian safety due to its reliability and precision. Its advantages become especially evident in environments where traditional visual-based systems fall short.

- High-Precision Distance Measurement: UWB enables centimeter-level accuracy in proximity detection, allowing forklifts and pedestrians to be monitored with clearly defined safety thresholds—even during high-speed or close-quarter operations.

- Unaffected by Visual Limitations: Because UWB relies on radio frequency rather than optics, it continues to function effectively in areas with poor visibility, such as blind corners, low-light zones, and between tall storage racks.

- Effective Across Complex Facility Layouts: UWB systems are well-suited for large warehouses, multi-level buildings, and dynamic traffic patterns where consistent coverage and flexible zone management are essential.

Considerations and Limitations

While UWB provides strong proximity precision and reliable performance in visually obstructed environments, it is not a complete safety solution by itself. Its effectiveness depends on how well the supporting infrastructure is designed and how clearly alerts and rules are integrated into daily operations. UWB focuses on “where objects are,” but not “why they are moving” or whether behavior is safe.

The table below summarizes the core strengths of UWB technology alongside key considerations for effective deployment:

| Strenghts | Limitations |

|---|---|

| High distance accuracy | Requires infrastructure planning |

| Works in visually obstructed areas | Best combined with processes and training |

| Suitable for complex layouts | Limited to proximity awareness |

Trio Mobil’s High-Precision UWB Proximity Detection System

Trio Mobil’s UWB-based safety system enhances situational awareness by creating structured proximity zones around forklifts, pedestrians, and critical areas. With automated alerts and real-time detection, it supports safe operations without disrupting workflow.

- Forklift–Forklift Proximity Detection: Detects and alerts operators when two forklifts come within a defined range, helping prevent collisions in narrow aisles and high-traffic zones.

- Forklift–Pedestrian Collision Avoidance: Uses pedestrian tags and onboard forklift units to alert both parties as they enter proximity, improving awareness in shared or low-visibility areas.

- Zone-Based Forklift Speed Control: Automatically slows down forklifts in predefined areas like intersections or loading zones, using fixed anchors to enforce safer driving behaviors.

How AI Advances Industrial Safety Systems

AI-powered forklift safety focuses on understanding how movement, behavior, and environment interact within daily operations. By analyzing visual and contextual data in real time, AI systems add a deeper layer of awareness beyond proximity alone. This approach helps safety and operations teams gain clearer insight into how risks emerge during routine activities and supports more informed decisions in dynamic material handling environments.

What AI Models Provide in Modern Safety Systems

Artificial intelligence offers real-time visibility into behaviors, movement patterns, and operational context. Instead of relying solely on distance, AI can interpret the environment and identify indicators of elevated risk.

How AI Vision Enhances Real-Time Visibility

Cameras mounted on forklifts or strategic facility points analyze visual data. AI models interpret motion, traffic flow, and situational factors that may create unsafe interactions. Alerts and insights are generated when risk patterns appear.

Benefits of AI-Powered Forklift Safety Systems

AI enhances safety by interpreting operational behavior in real time, providing actionable insight without relying solely on physical proximity data. Key benefits include:

- Real-Time Risk Recognition: Continuously analyzes visual and contextual data to identify potential hazards as they develop without waiting for incidents or manual reports.

- Behavioral Insight into Movement Patterns: Tracks how forklifts and pedestrians interact, helping teams understand recurring habits or unsafe behaviors that may lead to risk.

- Data-Driven Reporting and Trend Analysis: Converts observations into structured safety data, enabling teams to prioritize risks, monitor trends, and plan continuous improvements.

- Tagless Operation for Flexible Deployment: Operates independently of wearables, making it suitable for environments where distributing or enforcing tag usage is impractical.

Considerations and Adoption Requirements

AI-based forklift safety systems offer valuable behavioral insight and tagless detection, but they also require specific environmental conditions to perform optimally. These systems depend on camera visibility, appropriate placement, and consistent calibration to adapt to changing layouts. Unlike proximity-based technologies, AI does not measure exact distances - it interprets visual cues to detect potential risk.

The table below outlines the core benefits of AI-based safety systems, alongside important considerations for successful implementation:

| Benefits | Considerations and Limitations |

|---|---|

| Tagless pedestrian detection through visual analysis | Does not provide precise forklift-to-pedestrian distance measurement |

| Behavioral and PPE monitoring for deeper operational insight | Cannot detect through walls, pallets, or solid obstacles |

| Data driven reporting and trend analysis for continuous improvement | Performance depends on camera placement, lighting, and ongoing calibration |

AI-Powered Protection with Trio Mobil

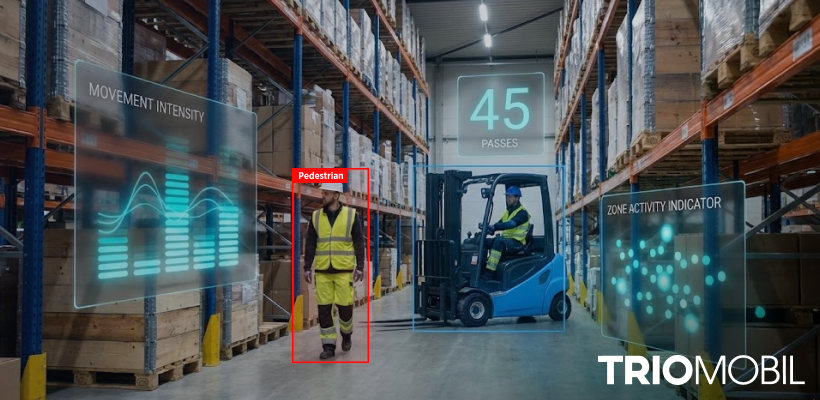

Trio Mobil’s AI safety technologies provide early awareness of forklift and pedestrian interaction risks by analyzing visual data, behaviors, and environmental conditions in real time.

Real-Time Visual Risk Detection at the Point of Operation with TRUE AI

The TRUE AI camera system actively interprets visual data at key risk points, enabling real-time alerts when pedestrian presence creates unsafe conditions.

- Continuously monitors defined zones like intersections, aisles, and dock areas for pedestrian movement.

- Detects activity in blind spots and generates alerts before proximity becomes critical.

- Identifies unsafe interaction patterns between forklifts and pedestrians during routine operations.

Turning Daily Operations into Actionable Safety Intelligence with AI Risk Radar

AI Risk Radar converts everyday forklift activity into structured insights that support proactive safety management and continuous improvement.

- Detects high-risk events such as near misses, unsafe load handling, or blind spot exposure.

- Applies risk scores to each event, allowing teams to compare risk levels across zones, time periods, or vehicles.

- Enables early intervention through automated alerts and optional controlled slowdown actions.

Combining AI Context and UWB Precision for Smarter Safety

Integrated AI + UWB layered safety brings together two complementary technologies to address different dimensions of risk in material handling environments. UWB delivers precise distance awareness, while AI provides contextual understanding of behavior and surroundings. When combined, these systems create a more complete view of forklift and pedestrian interactions, strengthening field awareness, reducing blind zones, and supporting more relevant alerts in dynamic industrial operations.

Why Layered Architectures Improve Field Awareness

Combining AI and UWB strengthens visibility by merging behavior-based detection with precise spatial awareness. This reduces blind zones and improves alert relevance.

How Combined Systems Work in Live Operations

AI and UWB function as a unified safety layer: UWB tracks precise proximity, while AI interprets behavior and environmental context. Together, they generate smarter alerts that reflect both where risks are and what is happening, adapting to real-time conditions.

- Intelligent Alerting: Combines distance and behavior for more relevant warnings.

- Connected Data Streams: AI and UWB inputs feed safety logic and reporting systems.

- Adaptive Zone Logic: Alert sensitivity adjusts based on real operational patterns.

Unique Advantages of Combined Approaches

- Broader perception range

- Stronger interpretation of real-world risk

- Scalable architecture for multi-site alignment

Planning and Operational Notes

- Requires coordinated deployment planning

- Works best when integrated into a continuous improvement program

Trio Mobil’s Combined AI + UWB Safety Architecture

Trio Mobil enhances forklift safety through a layered approach that uses AI and UWB together for broader operational awareness. This combined architecture powers Trio Safe AI, where Mobil AI forklift-mounted vision systems work in sync with UWB proximity detection to support both machine-level and environment-level visibility.

Tagless Detection and Behavioral Insight with AI

Within Trio Safe AI, Mobil AI forklift-mounted vision systems enable tagless pedestrian detection and behavior monitoring. AI analyzes visual data to identify pedestrians and observe operating patterns. This provides contextual visibility at the machine level, particularly in blind spots and high interaction areas.

Precise Proximity and Non-Line-of-Sight Awareness with UWB

UWB proximity detection adds accurate distance measurement between forklifts, pedestrians, and other vehicles. It operates without relying on line of sight, allowing awareness to extend through walls, pallets, and stacked materials. This supports consistent proximity monitoring in complex layouts where visual coverage alone is not sufficient.

Combined Awareness Across Dynamic Environments

By integrating AI and UWB, Trio Safe AI delivers both behavioral interpretation and spatial awareness at the same time. The system supports forklift to pedestrian proximity, forklift to forklift interactions, and zone based awareness while maintaining tagless detection and behavior monitoring. This layered approach helps reduce blind zones, improve alert relevance, and maintain consistent safety coverage across warehouses and production facilities without changing existing workflows.

Comparison Table of UWB, AI, and AI + UWB

| Capability | UWB Proximity | AI Detection | AI + UWB |

|---|---|---|---|

| Detects distance | Yes | Not based on distance | Yes |

| Detects behavior | No | Yes | Yes |

| Works without line of sight | Yes | Yes with cameras | Yes |

| Context understanding | Low | High | High |

| Suitability for complex environments | Medium to high | High | Very high |

| Best use case | Spatial awareness | Behavior and environment insight | Broad layered safety |

Unified Safety Performance with Trio Mobil’s Layered AI + UWB System

Forklift safety is no longer defined by a single technology. As operational environments become more dynamic and data-rich, the fusion of AI and UWB represents a necessary evolution - one that unites precise spatial awareness with real-time behavioral understanding.

By combining these technologies into a single, layered architecture, organizations gain a more complete picture of how risk develops - and how to intervene earlier, more effectively, and more consistently.

The Power of AI + UWB Fusion:

- Dual-layer detection: AI interprets context; UWB measures distance. Together, they reflect not just how close something is, but whether it matters.

- Reduced blind zones: UWB sees through obstacles, while AI detects pedestrians in high-risk zones like intersections or loading areas.

- Smarter alert logic: Events are processed using both proximity and behavior data, reducing false alarms and improving relevance.

- Consistency at scale: Layered systems adapt to site-specific conditions while supporting standardized safety practices across facilities.

Trio Mobil’s role is to bring this fusion to life through purpose-built solutions that align with real operational demands. With Trio Safe AI, teams benefit from a system where AI and UWB operate as one, enabling deeper insight without added complexity.

To explore how integrated safety can be applied in your environment, reach out to our team for a tailored discussion.

Disclaimer: Trio Mobil solutions are operator-assist aids. They do not replace safe working practices or prevent all incidents. Performance depends on operating conditions and configuration; see product documentation.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!