Warehouse Safety: A Comprehensive Guide to Forklift Pedestrian Safety

Warehouses are vital components of an effective supply chain operation. However, they can be dangerous places to work for various reasons, including but not limited to the presence of heavy machinery and equipment, narrow aisles, and bustling traffic density where pedestrians and forklifts operate closely. As a result, they require special attention and methods to promote a safe working environment for both forklift operators and pedestrians working around them.

This article will explore warehouse safety in depth by examining OSHA standards, different methods of achieving forklift-pedestrian safety, and the benefits of implementing a comprehensive safety system.

What is Forklift Pedestrian Safety?

Forklifts are very useful for warehouse operations. However, this does not change the fact that they are hazardous assets. Since forklifts weigh around 9000 lbs and can reach 6-12 mph speeds, pedestrians working around them without protection other than their safety helmets are vulnerable. According to the National Security Council’s forklift safety reports, in 2020, forklifts were involved in 7,290 non-fatal injuries, and in 2021, they were the primary source of 70 work-related fatalities. Therefore, it is essential to implement necessary safety measures to avoid injuries, collisions, and deaths.

Forklift pedestrian safety comes into play at this point. In essence, forklift-pedestrian safety creates a work environment where forklifts and pedestrians work together harmoniously without the fear of accidents. It is a combination of awareness, technology, training, and implementation of regulatory measures to prevent accidents and near-miss cases between forklifts and pedestrians.

Why is Forklift Pedestrian Safety Important?

Forklift pedestrian safety is essential for an effective warehouse operation. It is possible to prevent accidents, enhance operational efficiency, reduce costs, and, most importantly, save lives by just taking small steps to establish a safety system and culture.

Forklift Injury & Fatality Statistics

Warehouses are noisy work environments with heavy material handling equipment driving around narrow and dark aisles, carrying heavy loads, and operating around crowded shelves and racks all in the same place with pedestrians. They are prone to accidents, collisions, and fatalities by nature.

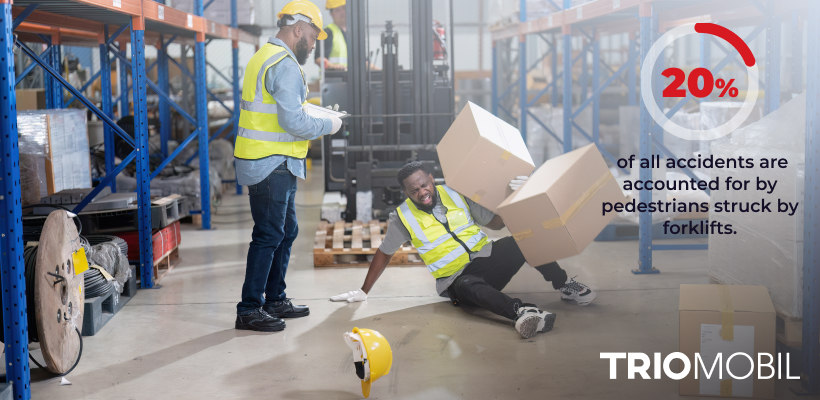

Statistics reveal that:

- Pedestrians getting hit by forklifts account for 20% of all accidents, making it the number two cause of forklift-related collisions and injuries.

- There are many cases where these accidents result in death. For instance, in 2021, pedestrians being struck by material handling equipment resulted in 337 fatalities. (Source: National Security Council - Pedestrian Vehicle Incidents Report)

However, many of these accidents and near-miss cases are avoidable if there is an effective safety system. To achieve that, establishing a forklift pedestrian safety system that protects forklift operators and the pedestrian workers around them is vital.

OSHA Forklift Pedestrian Safety Standards

OSHA (The Occupational Safety and Health Administration) is the foundation that provides training, education, and assistance to companies to promote a safe and healthy work environment. Recognizing that establishing these safety systems is essential, OSHA set strict standards for forklift operations and pedestrian safety.

OSHA forklift regulations include yielding the right of way to pedestrians, employing horns and safety signals at blind intersections, and many more. However, adherence to these regulations is not just a legal obligation. It is a matter of showing a commitment to creating a safe workplace where everyone feels secure.

Methods to Enhance Forklift Pedestrian Safety

To create and foster safer warehouse operations, companies must adhere to OSHA's safety regulations and standards. There are several ways companies can conform to OSHA's rules and protocols to enhance forklift pedestrian safety at the warehouses:

Forklift Pedestrian Detection System

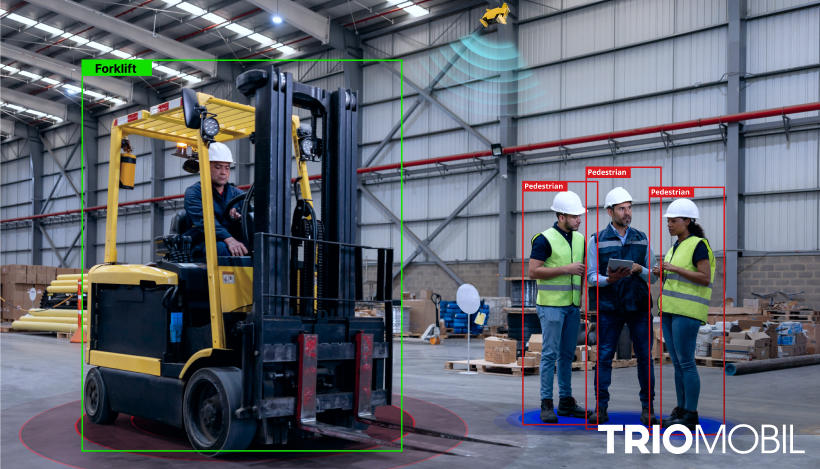

Implementing a forklift pedestrian detection system is one of the cornerstones of pedestrian safety. Leveraging cutting-edge technologies such as AI & IoT, these systems help detect pedestrians close to forklifts with cameras and sensors.

They provide the forklift driver and the pedestrian with audible and visual signs upon detection, alarming both parties about the potential danger. The risk of collision is significantly reduced by creating a real-time awareness of the situation, providing an extra layer of safety in bustling warehouse environments.

Forklift Pedestrian Collision Avoidance System

Creating awareness by detecting the pedestrians around the forklifts reduces the potential for accidents. However, it only partially eliminates the risks. That is why establishing a collision avoidance system is essential.

Forklift accident avoidance systems actively intervene to slow down forklifts automatically or, in some cases, stop them completely. These systems include sensors, alarms, wearable tags for pedestrians, and automatic braking mechanisms to avoid collisions.

By proactively preventing accidents, collision avoidance systems contribute to a safer work environment.

Forklift Pedestrian Safety Lights

Warehouses are large buildings with limited lighting conditions. These inadequate lighting conditions can easily pave the way for forklift-pedestrian collisions in busy, fast-paced warehouse environments.

However, forklift pedestrian safety lights designed to increase the forklifts' visibility help to avoid accidents by proactively warning pedestrians. These safety lights are placed on or under the forklifts, indicating to pedestrians nearby that a forklift is approaching and that they should exercise caution. It is a straightforward and effective way to increase safety in warehouse operations.

Forklift Pedestrian Safety Sensors

Forklift-pedestrian proximity sensors add extra protection to warehouse environments. These safety sensors vary in technology, ranging from ultrasonic to infrared sensors and laser to radar sensors. They detect pedestrians in the forklift's path and trigger alarms to warn pedestrians and operators. In some cases, they are used to trigger an automatic slow-down of the forklift.

Forklift pedestrian safety sensors help companies provide a secure work environment and minimize risks by proactively warning pedestrians and forklift operators and triggering alarms.

Forklift Pedestrian Safety Training

Lack of training is one of the main reasons for forklift pedestrian collisions. All of the forklift operators must go through necessary forklift training, and they should be certified to operate a forklift. However, more is needed to reach a safe work environment. It is also crucial that pedestrians go through special training underlining the necessary safety precautions.

Forklift pedestrian safety training covers necessary forklift training for operators and training the workforce to establish a safety culture and raise awareness. It is possible to avert hazardous collisions by educating employees on understanding blind spots, recognizing potential hazards, and adhering to safety protocols.

Benefits of Implementing a Forklift Pedestrian Safety System

The benefits of a forklift pedestrian safety system are not limited to preventing accidents and saving lives. In addition to enhanced safety at the warehouses, implementing a forklift pedestrian safety system brings many positive outcomes, from creating a safe work culture to streamlining operations.

Some advantages of implementing a forklift pedestrian safety system include:

Increased Productivity

Because of the reduced risk of accidents and injuries causing disruptions, a well-implemented safety system guarantees a smoother and more effective workflow and permits ongoing and uninterrupted operations.

In addition, since the workers are not constantly worried about their safety and health, they focus more productively on their work, resulting in increased productivity and overall efficiency.

Reduced Downtime

Forklift pedestrian accidents cause reporting, recovery, and inquiry delays. Forklifts require heavy maintenance after accidents, and in some cases, pedestrians cannot go back to work, requiring long treatment. As a result, operations are slowed down or ceased for short periods.

Businesses may drastically lower the incidence of accidents by investing in safety systems that actively prevent them, which will minimize interruptions to regular operations.

Positive Work Culture

When safety is prioritized, a healthy work culture where workers feel appreciated and cared for is created. This commitment to well-being fosters the workforce's sense of loyalty and dedication.

Furthermore, because prospective workers are increasingly weighing safety records when assessing potential employers, a solid safety culture helps draw in top talent.

Cost Savings

Advanced safety systems have a substantial initial cost, but there are significant long-term cost reductions. Preventing accidents lowers insurance rates, possible legal costs, and medical costs.

Additionally, the enhancement of staff morale and retention positively impacts overall cost-effectiveness.

Use Cases: Enhanced Forklift Pedestrian Safety

Warehouses in different sectors have different functioning systems due to the products and the size of the operations they contain. As a result, their safety vulnerabilities and requirements differ. Determining the company's safety requirements and implementing a solution to meet them successfully is essential to achieving high levels of forklift pedestrian safety,

There are different use cases where forklift pedestrian safety systems can be implemented to achieve the optimum results.

1. Enhancing Forklift - Pedestrian Safety At FMCG Warehouses with Limited Lighting

In the FMCG sector, cold and dark warehouses are needed for long-term storage of particular types of food. Trucks, forklifts, and pedestrians work together in these types of warehouses. Accidents between pedestrians and vehicles due to insufficient lighting are an essential problem in this industry.

Establishing a forklift pedestrian safety system to signal pedestrians that a forklift or truck is approaching to eliminate these types of accidents is crucial.

LED Lights and Holograms for Effective Traffic Management

LED lights are critical for forklift pedestrian safety systems. This solution requires the installation of LED lights near the entrances of the warehouse doors to signal pedestrians that a forklift or a truck is approaching. These lights can be in the form of a red LED light projected to the ground to warn pedestrians in case there is a forklift nearby.

In addition to the LED light system, a hologram system that reflects "Stop" or "Wait" commands for pedestrians can also be preferred, or both systems can be complementary.

Traffic lights can also be used to add an extra level of security. By placing traffic lights on the forklift' pathways that they commonly use with pedestrians, it is possible to control the traffic inside the facility. This solution is helpful for warehouses with high pedestrian and forklift numbers and crowded intersections to prevent collisions or near-miss cases between vehicles and pedestrians.

2. Eliminating Blind Spots with AI Cameras in Paper and Packaging Industry

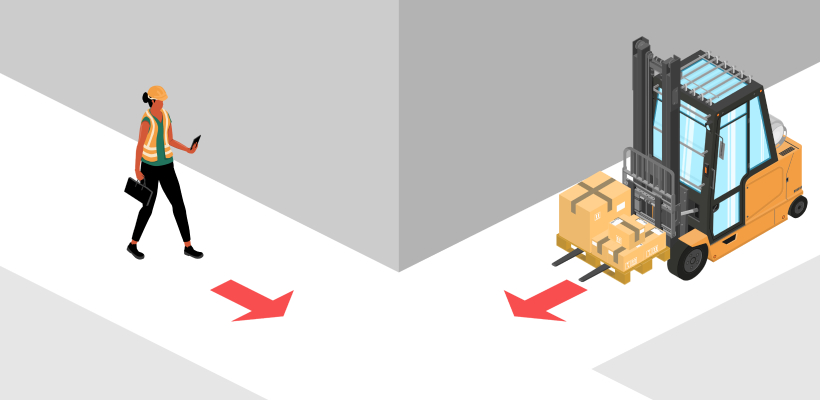

Limited visibility is one of the leading causes of forklift-pedestrian accidents. Yet, it is a fact that forklifts have to operate under these conditions in specific industries due to the nature of the products they are carrying.

For instance, forklift operators in the paper and packaging industry have big paper rolls, limiting their vision and creating blind spots. They are unable to see the obstacles in their path or pedestrians nearby.

However, it is possible to address these blind spots and help reduce the risk of incidents by implementing a forklift–pedestrian safety system that utilizes AI and IoT technologies.

Tagless Pedestrian Detection with AI Cameras

AI cameras help to identify pedestrians without the need for a sensor that they have to carry on them all the time. AI cameras, mounted at high warehouse spots, can detect pedestrians, forklifts, and vehicles with a bird's eye view. These cameras detect pedestrians or vehicles using real-time video analytics and edge-processing technologies.

Another way to effectively use AI cameras for forklift pedestrian safety is by mounting them on the forklift. These forklift-mounted AI cameras assist in addressing blind spots that a forklift driver might have, supporting broader awareness for both pedestrians and operators. The system works the same as the wall-mounted AI camera.

When a pedestrian is detected in hazardous proximity to a forklift, AI cameras trigger the system to warn the operator and the pedestrians with audible and visual signs. Forklifts are automatically slowed down, and accidents are prevented.

3. Increased Safety at Busy Intersections and Narrow Corridors in Manufacturing Facilities

Accidents may seem inevitable in a bustling warehouse with busy intersections and narrow corridors with high pedestrian and forklift traffic. For instance, forklift operators are busy carrying heavy loads and working close to pedestrians in white goods manufacturing facilities.

In the event of unattentive or reckless behavior, forklifts and pedestrians collide, resulting in serious injuries. These types of accidents are common in most white goods manufacturing warehouses. However, an effective safety system helps to avoid forklift pedestrian collisions in these high-risk areas.

Automatic Forklift Slow-Down with UWB Sensors

As mentioned before, proximity sensors are one of the primary components in forklift pedestrian safety systems. UWB sensors utilize IoT technologies to provide proximity detection for forklifts and pedestrians. Sensors are installed on the forklifts, and pedestrians are provided with wearable tags that they can easily carry.

Pedestrians may not be able to see a forklift approaching them in a loud environment. The shelves and racks could limit their vision, or they may walk on a narrow path while working.

In the event of dangerous proximity of forklifts and pedestrians, these UWB sensors detect each other, and the system triggers alarms to alert both parties of the potential danger.

Thanks to the alarms, pedestrians are warned and allowed to take necessary precautions. In addition, the sensors on the forklifts trigger the system to automatically slow down forklifts and set their speed to a safe limit in two stages.

These UWB systems help to achieve forklift pedestrian safety and provide a safer work environment.

Trio Mobil's Forklift Pedestrian Safety Systems

Establishing the correct forklift pedestrian safety system is crucial because it changes according to different safety requirements for various industries and their warehouse operations.

As Trio Mobil, we offer adaptable and scalable solutions to meet our customers' safety needs. Our comprehensive solutions include UWB and AI-based collision avoidance systems offering 360-degree protection for forklift operators and pedestrians.

For more detailed information about our cutting-edge, modular, plug-and-play solutions, browse our website or request a demo to experience how our forklift pedestrian safety system works.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!