AI-Powered Forklift &

Pedestrian Safety

Beyond Blind Spots

Forklifts are involved in 90,000+ incidents every year — most caused by blind spots and busy pedestrian areas.

Trio Mobil supports safer operations with multi-layered detection and real-time collision avoidance assistance.

Blind Spot Awareness – Instantly detects pedestrians, even in low-visibility areas.

Smart Zones - Creates dynamic safety zones that assist collision avoidance at intersections and high-risk traffic points.

Operator Alerts - Real-time visual and audio alerts to help operators respond faster.

Trusted By 2,000+ Leading Brands

AI-powered forklift and pedestrian safety platform, chosen by industry leaders to reduce risks and enhance workplace performance.

Smarter Industrial Safety.

Stronger Operational Control.

Monitor

AI-powered systems continuously monitor forklift-pedestrian proximity, blind spots, and traffic patterns to support collision avoidance awareness.

Detect

Multi-layered technologies detect hazardous interactions instantly and trigger timely alerts to help operators and pedestrians react before situations escalate.

Prevent

Data-driven insights enable ongoing risk reduction, supporting safer traffic flows and strengthening a prevention-first safety culture.

Prevention-First Safety Platform

Trio Mobil helps you enhance forklift and pedestrian safety with intelligent, real-time with best in class AI-powered technology.

Near-miss

Incidents

Operational

Efficiency

AI-Powered Pedestrian Safety

Tagless and Tag-Based Detection for Maximum Protection

Real-Time Detection – Continuously monitors pedestrian and vehicle movements

Proximity Alerts – Provides instant audiovisual alerts to support operator awareness

Smart Speed Control – Assists with automatic speed limitation

See Beyond Blind Spots

Fusing Multi-Layered Technology for Smarter Blind Spot Awareness

All-Direction Monitoring – Detects movement from every angle

Layered Safety Detection – Combines AI vision and UWB proximity sensing for enhanced collision avoidance coverage.

Seamless Integration – Works with all types of forklift models and brands

Intelligent Zone Safety Management

Visual alerts and smart controls that assist collision avoidance in high-traffic workflows

Real-Time Alerts – When pedestrians or vehicles enter collision-risk zones.

LED Integration & Door Control – Improves visibility at blind intersections.

Dynamic Zone Adaptation – Adjusts safety logic based on traffic behavior.

AI Risk Radar — Your 24/7 Digital EHS Inspector

Continuous Risk Detection for Safer Workplaces

100+ Use Case Detection – Real-time monitoring of collisions, compliance, and unsafe practices

Near-Miss Analysis – Surfaces close-call events early to support proactive interventions

Smart Insights – Delivers instant answers with supporting video to accelerate decision-making

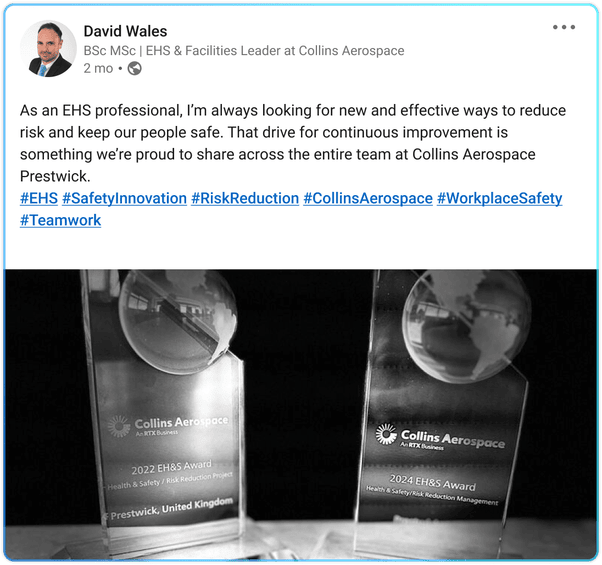

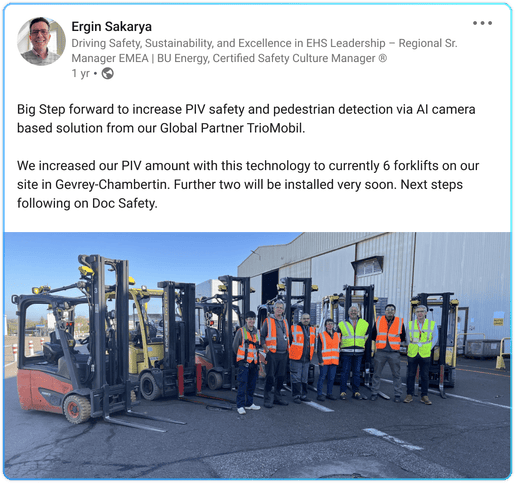

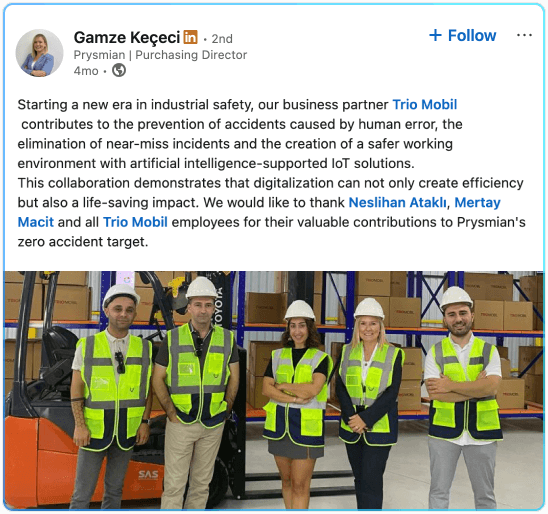

What Industry Leaders Say

See how industry leaders are transforming safety and efficiency with Trio Mobil — in their own words.

Measurable Impact That Pays Off

Trio Mobil’s Prevention-First Safety Platform delivers a 3-4× average ROI across global deployments — turning safety investments into lasting business value.

Incident Saving Cost Avoidance

Prevents high-severity incidents that can cost $500K–$1M+ per case.

Efficiency

Gains

Reduces downtime and equipment damage while improving traffic flow.

Compliance & ESG Alignment

Simplifies reporting, strengthens sustainability metrics, and supports global safety standards.

Insurance & Damage Savings

Lowers premiums and facility repair costs through data-backed safety improvements.

Global Coverage

Why Choose Trio Mobil?

Layered AI + UWB Safety

Multi-layered detection that enhances operator awareness in the most critical zones

Prevention-First Safety Platform

Prioritizes pedestrian protection with real-time safety triggers

Proven by Global Enterprises

Delivering measurable improvements in both safety and operational efficiency.

Global Account Management

Strategic support for enterprise customers, aligning projects with safety and efficiency objectives.

Continuous Risk Detection

Monitoring of 100+ risk categories, giving EHS teams real-time visibility

Smart Zone & Traffic Control

Dynamic alerts and safer site flows in high-traffic intersections.

SIF Risk Reduction

Targeted support for reducing Serious Injury & Fatality (SIF) exposures with constant oversight.

Customer Success Team

Continuous collaboration with customers to assist in maximizing solution use and long-term impact.

Trusted By 2,000+ Leading Brands

AI-powered forklift and pedestrian safety platform, chosen by industry leaders to reduce risks and enhance workplace performance.

Discover the Right Safety Solution for Your Business Needs

We'll help you find the right fit — a solution built to advance your safety goals while supporting day-to-day operations.

Frequently Asked Questions

The most effective systems combine multiple detection technologies, because no single method can address every risk in a busy industrial environment.

Trio Mobil uses a multi-layered protection approach that includes:

- AI-powered, tagless pedestrian detection

- UWB proximity sensing for precise distance measurements

- Real-time alerts that support operator awareness

- Zone-based rules such as speed control

This layered structure helps operators notice pedestrians earlier and supports safer operations without relying on one technology alone.

The most reliable strategy combines operator training, site rules, and assistive technology.

Trio Mobil provides:

- AI vision to detect pedestrians and unsafe proximity

- UWB wearables/tags for consistent detection in blind spots

- Assistive alerts delivered directly to forklift operators

- Smart Zones that automatically adjust speed in high-risk areas

These tools help increase situational awareness and reduce human error in fast-moving areas.

EHS leaders are adopting technologies that improve both risk visibility and operator awareness, including:

- AI pedestrian detection

- UWB proximity alerts

- 360° awareness sensors

- Zone-based safety automation

- Real-time analytics and near-miss insights

Trio Mobil combines all of these into one scalable platform, designed for large and complex facilities.

AI helps by identifying unsafe behaviors, risky interactions, and pedestrian presence in real time, even in visually complex environments.

Trio Mobil’s AI:

- Recognizes pedestrians without tags

- Detects high-risk proximity between forklifts and people

- Provides timely alerts to assist operators

AI-powered forklift safety system is an assistive layer that enhances visibility and risk awareness.

AI detection works without tags, using cameras and computer vision to recognize pedestrians.

UWB provides precise distance measurement, even without line of sight, and works in:

- Blind corners

- Behind racks

- Low-light conditions

- Crowded layouts

Trio Mobil unifies both technologies, giving facilities the advantage of tagless + tag-based detection in one system.

Consider these factors:

- Do you have blind spots?

- Are pedestrians always tagged?

- Do you need zone-level speed control?

- How many forklifts operate at the same time?

- Do you require analytics or reporting?

Trio Mobil offers flexible configurations, allowing facilities to mix AI vision, UWB proximity, and Smart Zones based on their exact risk profile.

Yes. AI vision can detect pedestrians taglessly, using cameras and machine learning.

Trio Mobil’s AI detection recognizes:

- People

- Movement patterns

- Unsafe approach distances

- Unsafe Behavior

Tagless AI works great in open areas, while UWB wearables strengthen detection in tight aisles, narrow corridors, and occluded zones.

A multi-layered system uses several complementary technologies to cover different risk scenarios.

Trio Mobil’s layers include:

- AI (tagless) pedestrian detection

- UWB proximity (tag-based) alerts

- Zone safety automation

- Real-time risk monitoring analytics

This reduces reliance on any single technology and provides a more consistent safety experience across the facility.

Blind spots are the most common locations for near-misses.

Trio Mobil addresses these areas through:

- AI cameras that monitor complex sightlines

- UWB sensors that detect presence even when the operator cannot see it

- Intersection beacons that warn forklifts entering shared paths

- Smart Zone Management

These tools help operators navigate complex layouts more confidently.

Forklift safety technologies decreases the risk of accidents

Trio Mobil provides operator-assist technology designed to:

- Increase situational awareness

- Identify risk

- Deliver timely alerts

- Support safer decision-making

Performance depends on site conditions, configuration, and maintenance; measured over time and defined scenarios.

Traditional safety measures such as mirrors, signage, floor markings, or manual protocols offer passive protection.

Trio Mobil provides a multi-layered protection approach that combines:

- AI-powered, tagless pedestrian detection

- UWB proximity sensing for precise distance measurement—even without line of sight

- Real-time alerts for operators

- Zone-based speed control and assistive interventions

This layered structure helps operators become more aware of surrounding risks and supports safer, more predictable operations.

Yes. Trio Mobil’s safety system is designed to be vehicle-agnostic and works with:

- Electric, diesel, LPG forklifts

- Stand-up / sit-down models

- AGVs and AMRs

- Mixed-brand or high-volume fleets

No fleet replacement is required. The solution integrates seamlessly with existing equipment.

Trio Mobil offers tag-based and tagless (AI vision) detection options:

- AI cameras recognize pedestrians in real time

- UWB wearable devices or tags ensure precise detection in complex layouts

- Alerts are provided through visual, audio, or operator-assist cues

- Optional automatic slow-down or speed-limiting assist can be activated in defined risk zones

This flexibility allows facilities to choose the right level of protection for each area.

Yes—this is one of the key advantages of the multi-layered approach.

- AI cameras cover wide angles and dynamic zones

- UWB sensors detect objects and people even when they are not visible to the operator

- Forklift-to-pedestrian and forklift-to-forklift interactions are monitored continuously

This enables effective support in high-risk areas such as intersections, rack aisles, and loading docks.

Absolutely. In addition to risk reduction support, the system provides real-time operational intelligence, including:

- Forklift utilization and idle time

- Driver behavior insights

- Heatmaps of high-risk or high-traffic areas

- Automated reporting for continuous improvement

This helps EHS and operations teams make data-driven decisions that improve productivity and workflow efficiency.

Trio Mobil includes Smart Zones that allow facilities to assign custom safety rules to specific locations:

- Automatic speed control in designated zones

- Visual or audible warnings for operators

- Pedestrian-only vs. mixed-traffic zones

- Temporary rules for maintenance or high-activity periods

This increases consistency and reduces the burden on operators in complex layouts.

The system includes detailed analytics and reporting that highlight:

- Near-miss trends

- Pedestrian-forklift interaction frequency

- Unsafe behavior patterns

- Improvements over time

- Comparison across shifts, operators, and areas

These insights give organizations a clear view of safety performance and help track improvements month over month.

Installation is typically fast and minimally disruptive.

Most forklifts can be equipped within a few hours, and zone infrastructure can be deployed around existing operations with minimal downtime.

Deployment plans are tailored to each facility’s layout and shift schedule.

Trio Mobil combines AI vision + UWB + Real-time analytics in a single unified platform, enabling:

- True multi-layered detection

- Both tagless and tag-based detection

- Scalable architecture across forklifts, pedestrians, and fixed infrastructure

- Enterprise-level reporting and integrations

- Proven deployments across global manufacturing, logistics, automotive, food & beverage, and retail facilities

This creates a higher level of visibility and risk intelligence compared to single-technology systems.