Not all safety incidents carry the same weight. A scraped pallet or bruised bumper may interrupt a shift, but a struck pedestrian or a tip-over can alter a life forever. These are SIFs: Serious Injuries and Fatalities. And in forklift operations, where heavy machinery and human presence frequently intersect, the potential for such events is always present even if infrequent.

Most safety programs aim to reduce the number of incidents. But SIF prevention is about something deeper: reducing the severity of consequences when something goes wrong, and focusing resources on risks that can’t afford to be ignored.

This article explores how SIF prevention differs from standard safety practices, where high-severity risks emerge in forklift operations, and how facilities can use real-time tools and smarter strategies to better protect their people from worst-case outcomes.

What Is SIF Prevention?

SIF stands for Serious Injury and Fatality. It is a category of safety incidents that result in life-altering outcomes or death. SIF prevention, then, is the strategic effort to identify and address the conditions that lead to these high-severity events, even if they occur infrequently.

Unlike general safety programs that focus on reducing incident rates or improving housekeeping, SIF prevention targets the small percentage of risks that carry disproportionate consequences. It asks: “Which tasks, behaviors, or conditions, if they go wrong, could result in catastrophic harm?”

A key insight behind SIF prevention is that serious incidents don’t always follow a pattern of near misses or minor injuries. Many fatal or life-threatening events happen suddenly, with no historical trail.

In forklift operations, this might include:

- A single missed detection in a blind spot

- One lapse in speed control at a busy crossing

- A lone worker falling unconscious in a low-traffic zone

Where SIF Risks Arise in Forklift Operations

Forklifts are indispensable in industrial operations but they’re also involved in some of the most severe incidents on the floor. Not every hazard leads to injury, but certain patterns are consistently linked to Serious Injury and Fatality (SIF) events. Recognizing where these high-risk scenarios arise is the first step toward smarter, more focused prevention.

Pedestrian Interaction in Shared Zones

In many facilities, pedestrians and forklifts operate within the same physical space, especially at intersections, entryways, and staging zones. When people and machines move unpredictably, and without clear visibility, misjudgments can occur in seconds. A distracted pedestrian, an operator with limited line-of-sight, or a forklift reversing into a shared path: each creates conditions where minor oversight can lead to catastrophic outcomes.

Speed-Related Incidents in Confined Spaces

Speed is often underestimated in its impact on severity. A forklift traveling through a narrow aisle or across a crowded dock at even modest velocity may not have time to stop when something, or someone, enters its path. These environments demand slower, more controlled movement, but without automatic enforcement, compliance can vary. When speed meets congestion, the consequences escalate quickly.

Limited Visibility and Blind Spots

Forklifts frequently operate with compromised visibility, whether due to elevated loads, obstructed mirrors, or environmental factors like dim lighting and crowded racking. Operators may not detect someone walking into a blind zone until it’s too late. Visibility limitations are a root cause in many SIF-related investigations, especially those involving rear-end swing, corner turns, or reverse movement.

Lone Worker Exposure

SIF risks don’t only occur in busy zones. Lone workers, such as maintenance staff, overnight teams, or personnel retrieving inventory in back zones, face serious risks when working outside of line-of-sight. If struck, trapped, or immobilized without detection, their chance of timely assistance drops significantly. The longer the delay, the higher the severity.

Manual-Automated Crossovers

As facilities adopt more automation, new risk points emerge. Automated Guided Vehicles (AGVs), robotic cleaners, and autonomous tuggers often follow programmed paths that intersect with human or forklift workflows. If systems aren’t integrated, or if communication between machine types is absent, manual-automated handoffs and overlaps can become high-stakes blind spots.

How SIF Prevention Goes Beyond Standard Safety Practices

Most safety programs are designed to reduce the frequency of incidents. They track minor collisions, coach unsafe behaviors, and invest in training to promote situational awareness. These efforts are essential but they don’t always reach the root causes of serious injuries and fatalities (SIFs).

SIF prevention takes a more risk-driven, consequence-focused approach. Instead of asking how often an event happens, it asks how bad could it be if it does?

This mindset shift introduces several key differences:

Risk Severity Over Frequency

Standard safety tends to prioritize high-frequency events like minor bumps, ergonomic strain, or low-speed impacts. But many SIFs stem from rare, high-consequence scenarios: a pedestrian in a blind spot, an unsupervised lone worker, a forklift traveling too fast through a congested zone.

SIF-focused strategies invest in identifying these low-probability, high-impact risks early and mitigating them through layered protection and smarter controls.

Real-Time Intervention, Not Just Warnings

Traditional tools like mirrors, signs, and beacons rely heavily on human vigilance. But in SIF-prone situations, milliseconds matter. Operator-assist technologies, such as proximity detection, zone-based speed control, and AI-powered pedestrian recognition, support trained drivers by delivering real-time alerts when attention alone isn’t enough.

This does not replace safe operating practices, it also strengthens them where human limitations create vulnerability.

Integrated Systems Over Isolated Measures

Conventional safety programs often use isolated tools: one system for forklifts, another for AGVs, another for pedestrians. This siloed approach creates gaps. A unified, fleet-wide system connects all vehicle types and zones to provide detection, alerts, and responses work together to support consistent SIF prevention across the entire facility.

How Technology Supports SIF Prevention in Forklift Operations

Technology doesn’t replace safe behavior but it can help prevent serious incidents by assisting trained operators in real time. In forklift operations, this assistive layer is critical for identifying high-severity risks before they escalate.

Here’s how modern safety technologies contribute to SIF prevention:

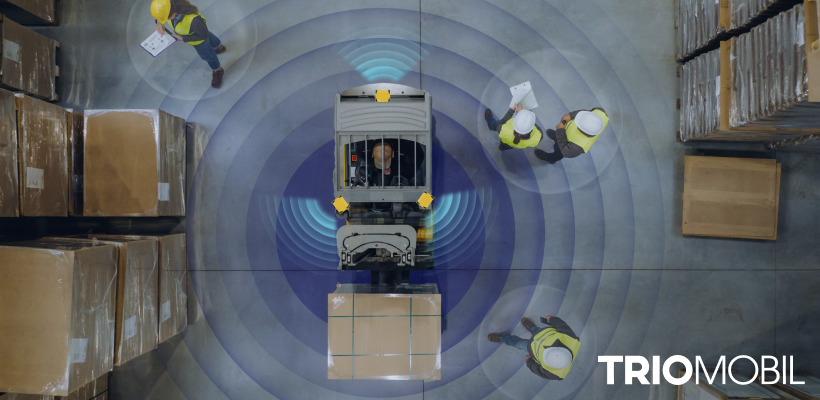

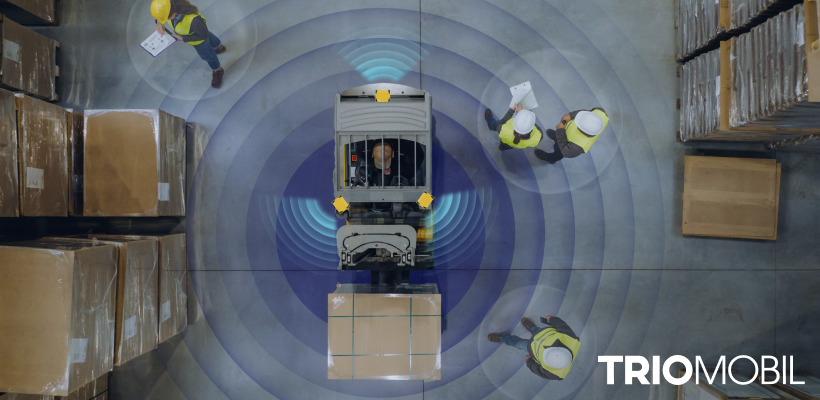

- Proximity detection systems create a digital safety zone around forklifts. When a pedestrian or another vehicle enters this zone, the system issues targeted audiovisual alerts, giving the operator more time to respond and reducing reliance on mirrors or manual scanning.

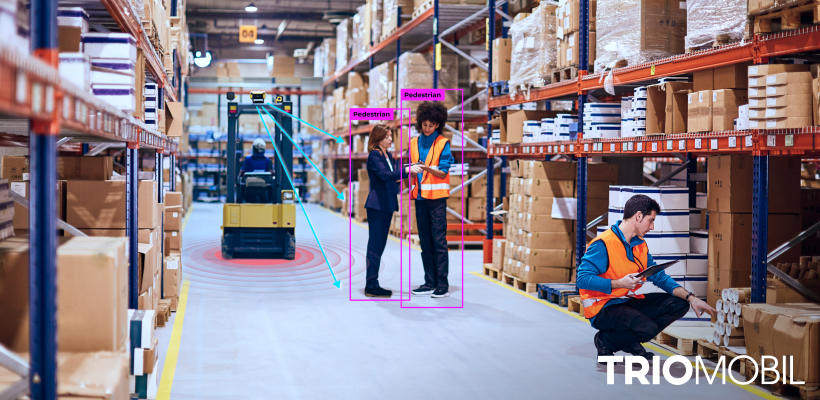

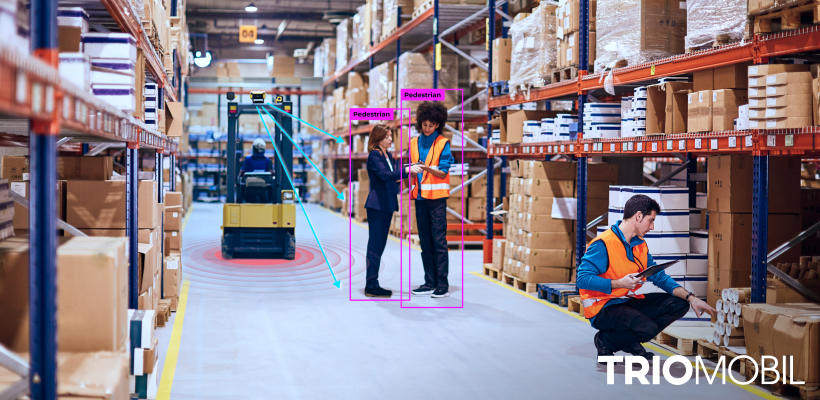

- AI-powered pedestrian detection can recognize people, even untagged visitors or contractors, in blind spots or low-visibility areas. This supports safer navigation without flooding the operator with constant false alarms.

- Zone-based speed control automatically slows forklifts when entering high-risk areas like intersections, loading docks, or narrow aisles. Speed adjustments happen without driver input, promoting consistent behavior even during high-pressure operations.

- Unified systems connect multiple vehicle types (manual forklifts, AGVs, cleaners) into a single safety network. This allows for coordinated alerts and prevents collisions between different equipment classes.

- Lone worker monitoring uses motion-sensitive tags to detect inactivity in low-traffic areas. If a worker becomes unresponsive, alerts are sent to supervisors helping to enable timely assistance in isolated zones.

- Fleet-wide data monitoring tracks behavior trends, zone activity, and incident logs across all equipment. These insights allow safety managers to spot high-risk patterns and intervene proactively.

Together, these technologies don’t guarantee incident prevention but they significantly reduce the likelihood and severity of SIF-related events when properly maintained, calibrated, and used in support of operator training.

Supporting SIF Prevention with Trio Mobil’s Forklift Safety Systems

At Trio Mobil, our solutions are built to assist trained operators and safety teams in identifying and responding to high-consequence risks, especially in environments where forklifts and pedestrians share space. Each system in our safety platform contributes to Serious Injury and Fatality (SIF) prevention by targeting the conditions where these events are most likely to occur.

- TRIO SAFE AI - Layered Forklift and Pedestrian Safety helps address one of the leading causes of SIFs: pedestrian-vehicle interaction in blind zones. By creating a 360° detection field around forklifts, the system delivers clear, directional alerts to operators when people or other vehicles enter critical range.

- Zone Controls reduces the risk of high-speed collisions in confined or congested areas. Forklifts automatically slow down in predefined danger zones, removing variability from operator behaviour and providing consistent compliance where speed matters most.

- Lone Worker Safety adds protection in areas that may be out of view or low in traffic. Motion-sensitive tags monitor for inactivity and signal supervisors if a worker becomes unresponsive to support timely intervention in otherwise unnoticed events.

- Forklift Fleet Monitoring and Analytics bring all vehicle and zone data into a single, unified view. Safety teams can review incidents, spot trends, and identify behaviour patterns leading to the insights to prioritize resources and refine safety strategies based on real-world usage.

To see how Trio Mobil can help strengthen your forklift safety strategy with proactive, real-time risk detection, get in touch with our team for free safety consultancy.

Disclaimer: Trio Mobil solutions are operator-assist aids. They do not replace safe working practices or prevent all incidents. Performance depends on operating conditions and configuration; see product documentation.