10 Rules for Forklift Safety: How AI Technology Supports Safer Workplaces

Forklifts are essential for productivity in warehouses and factories, but they also rank among the leading causes of workplace accidents. OSHA outlines clear rules to reduce these risks, yet in fast-moving operations, maintaining safety can be challenging. Blind spots, congested areas, and time pressure often put both operators and pedestrians at risk.

This is where technology provides support. Trio Mobil solutions help trained operators notice hazards sooner, reduce near-miss risks, and strengthen compliance with OSHA rules. The most effective approach is layered safety, combining AI cameras and pedestrian tags for reliable performance in diverse conditions.

In this article, we explore 10 essential forklift safety rules and how operator-assist systems can help apply them more effectively in real-world environments.

Rule 1: Keep Pedestrians Visible

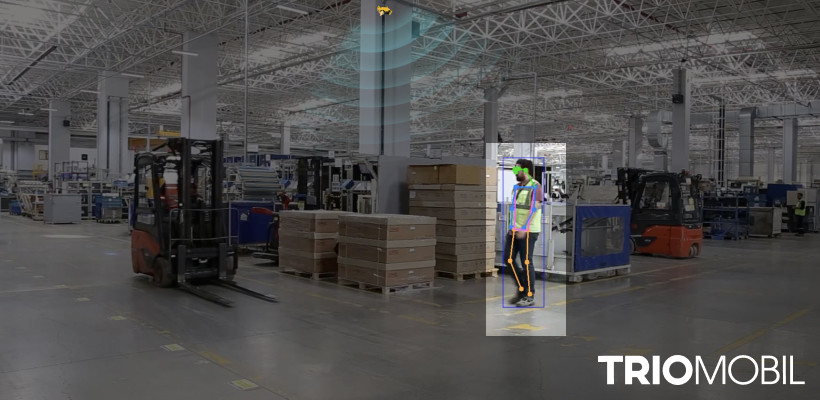

One of the most important principles in forklift safety is maintaining clear visibility of pedestrians. According to OSHA, nearly 20% of all forklift-related incidents involve a collision with a pedestrian. In facilities where forklifts and people share the same space, such as warehouses, production floors, and loading docks, the risks increase significantly. The challenge is that forklifts often operate with large or high loads that obscure the driver’s line of sight, and pedestrians may not always follow designated walkways.

Traditional approaches, such as painted floor markings or mirrors, help but have limitations. Mirrors don’t cover all blind spots, and markings rely on pedestrians staying within their boundaries. In practice, it’s not always possible to fully separate forklift traffic from pedestrian movement. This is where technology provides an added layer of safety by assisting operators in noticing hazards sooner.

Trio Mobil’s operator-assist solutions use a layered safety approach:

- AI cameras detect pedestrians in defined zones, even when visibility is blocked by large loads or warehouse structures.

- Pedestrian safety tags communicate directly with forklifts, making the operator aware of someone nearby even if they are behind obstacles or in poorly lit conditions. It also increases pedestrian awareness by vibrating and alarming the pedestrian.

- Together, cameras and tags reduce the risk of blind-spot incidents by alerting operators only when a pedestrian is in a hazardous position.

For more practical solutions to reduce pedestrian risks, see our guide: 10 Must-Have Forklift Safety Devices for Safer Operations.

Rule 2: Reduce Forklift-to-Forklift Collision Risks

Forklifts don’t just pose risks to pedestrians. They also pose risks to each other. In large warehouses, manufacturing plants, and logistics centers, it’s common to have dozens or even hundreds of forklifts operating at the same time. This high traffic density increases the likelihood of collisions, especially in blind intersections, narrow aisles, or areas with obstructed sight lines.

Forklift-to-forklift collisions can be particularly costly. Repairs, replacement parts, and downtime for two machines can quickly add up to thousands of dollars, not to mention the disruption to operations.

Trio Mobil’s operator-assist technology provides an additional layer of support through forklift-to-forklift collision avoidance. Using ultra-wideband (UWB) proximity detection, forklifts are equipped with safety units that continuously measure the distance between vehicles. When two forklifts approach each other too closely, the system:

- Sends visual and audible alerts to both drivers.

- Can trigger controlled deceleration, helping operators slow down before a collision risk escalates.

- Functions even in loud or visually obstructed environments where operators might otherwise miss cues.

For a broader look at how different systems perform in collision avoidance, read Evaluating the Effectiveness of Forklift Safety Systems: A Comparative Analysis.

Rule 3: Address Blind Spot Hazards

One of the most persistent challenges in forklift safety is the issue of blind spots. Forklifts often carry large or high loads that obstruct forward visibility. When driving in reverse, operators may also struggle to see pedestrians or other forklifts, especially in areas with clutter, racking systems, or poorly lit corners. According to OSHA, lack of visibility is a contributing factor in a significant percentage of forklift accidents, particularly those involving pedestrians.

Trio Mobil’s operator-assist systems are designed to help operators address blind spot hazards in real time. The TRUE AI camera system uses advanced video analytics to detect pedestrians within defined danger zones. Unlike conventional cameras, which simply display footage, AI-powered cameras analyze the environment continuously and trigger alerts when pedestrians move into a high-risk area.

When paired with pedestrian safety tags, this layered safety approach strengthens detection in challenging conditions:

- AI cameras provide wide coverage and assist with tagless detection in open areas.

- Tags add reliability in occluded or back-lit environments, providing operators are alerted even if the camera’s line of sight is blocked.

- Smart alerting minimizes false alarms by notifying operators only when pedestrians are in zones where collisions are possible, reducing “alarm fatigue.”

Rule 4: Control Forklift Speed in High Risk Zones

Speed is one of the biggest factors in forklift-related accidents. OSHA highlights that forklifts must always be driven at a speed that allows the operator to stop safely. However, “safe speed” is not always easy to define since it depends on conditions such as pedestrian density, aisle width, floor surface, and visibility. In busy warehouses or production areas, operators may unintentionally drive too fast, particularly when under pressure to meet productivity targets.

Excessive speed increases stopping distance and reduces reaction time. It also raises the risk of tip-overs, which account for nearly one-quarter of all forklift fatalities. Even a slight increase in speed can turn a near-miss into a serious accident, especially in areas like intersections, dock doors, or pedestrian-heavy walkways.

Trio Mobil’s operator-assist solutions use zone-based speed control to help manage this risk. With the help of fixed “zone anchors” installed around the facility, forklifts automatically reduce speed when entering pre-defined danger zones. These zones can include:

- Loading docks where pedestrians and forklifts interact frequently.

- Narrow aisles where visibility is limited.

- Areas near automated doors where forklifts may otherwise approach too quickly.

To understand why speed management is critical, explore 10 Reasons to Use Forklift Safety Systems.

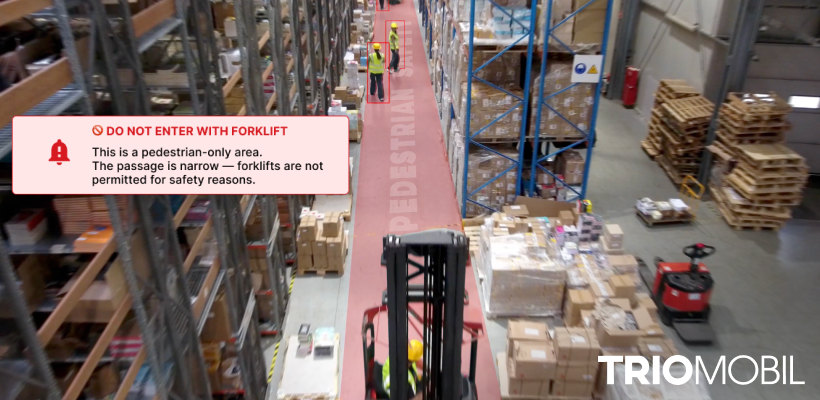

Rule 5: Manage High-Traffic Zones Safely

Some areas of a facility are inherently riskier than others. Loading docks, intersections, production lines, and machine zones are high-traffic environments where forklifts, pedestrians, and sometimes automated equipment must interact. OSHA emphasizes extra caution in these areas, noting that congestion and poor visibility often contribute to accidents.

The risks in high-traffic zones come from several factors:

- Unpredictable pedestrian movement, such as workers crossing aisles unexpectedly.

- Forklifts entering and exiting dock doors or intersections where sight lines are limited.

- Shared spaces with other machinery, such as AGVs (Automated Guided Vehicles) or robotic cells.

- Noise and distractions that make it harder for operators to notice hazards.

Trio Mobil’s operator-assist technology addresses this challenge through integrated traffic management tools:

- AI cameras monitor intersections, dock areas, and machine zones to detect pedestrians entering danger areas.

- Zone anchors trigger automatic forklift slowdowns when a vehicle enters a pre-defined high-risk space.

- Traffic lights and audiovisual alerts provide additional signals to operators and pedestrians, creating a shared language of safety.

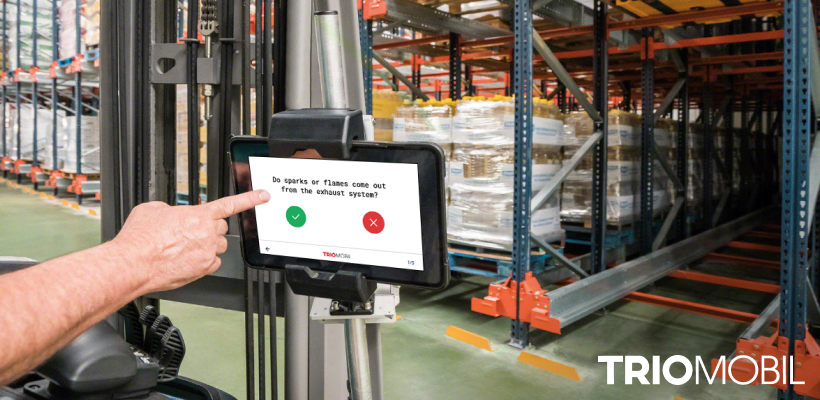

Rule 6: Perform Daily Pre-Shift Checks

OSHA requires forklift operators to perform a safety check before the start of each shift. This includes inspecting brakes, steering, controls, warning devices, mast, and tires to confirm that the equipment is safe to use. These inspections are not just a formality since many accidents trace back to poorly maintained forklifts with issues such as worn brakes, leaking hydraulics, or malfunctioning lights.

In practice, however, pre-shift inspections are often rushed or inconsistently documented. Paper checklists can be misplaced, filled out superficially, or forgotten altogether during busy shifts. This creates a gap between regulatory compliance and actual safety practice.

Operator-assist technology helps close this gap. Trio Mobil integrates digital pre-operation checklists into its FleetBridge platform, allowing operators to complete inspections directly on a mobile device or forklift-mounted screen. This approach provides several benefits:

- Accountability: Each inspection is logged digitally with operator credentials and time stamps.

- Consistency: Mandatory fields prevent operators from skipping steps, encouraging thorough checks.

- Visibility: Managers can access real-time data on inspection results, spotting patterns across the fleet.

- Integration: If a defect is identified, it can be linked directly to maintenance workflows for faster resolution.

Rule 7: Improve Loading Dock Safety

Loading docks are among the highest-risk areas in warehouses and factories, where forklifts, pedestrians, and trucks operate in close proximity. Accidents often occur due to:

- Limited visibility caused by trailers, stacks, or dock doors

- Trailer creep or early departure during loading and unloading

- Congestion from simultaneous vehicle and pedestrian activity

- Inadequate speed control near dock edges or door thresholds

Trio Mobil’s TRUE-AI real-time video analytics camera detects people and vehicles around dock doors and approach lanes, then automatically triggers safety systems. These include traffic lights and audio alerts for operators and pedestrians, as well as sensor-based door interlocks that open only when conditions are safe. The system integrates with wheel chocks and dock locks to manage a safe loading sequence and logs event data and short video clips on the cloud platform for review and reporting.

Together, these technologies help maintain a safer, more controlled loading dock environment without disrupting operational flow.

Key benefits include:

- Increased awareness at the dock edge and trailer entrance with AI-assisted pedestrian detection and alerting.

- Greater consistency in approach speed through zone-based slowdown near doors and staging areas.

- Support for safer pedestrian movement with tagless or tag-based alerts in congested staging zones.

- Improved coordination at busy doors using integrated traffic lights and audiovisual signals that align with site rules.

By combining AI cameras, UWB proximity, and zone-based controls, organizations can reduce exposure to dock-related risks while maintaining flow during loading and unloading.

Rule 8: Train and Protect Operators

Training is the foundation of forklift safety. OSHA requires that every forklift operator be trained and certified before operating equipment, and that refresher training be provided periodically or after an incident. Well-trained operators are more likely to drive responsibly, respect speed limits, and stay alert to their surroundings. However, even the best training cannot account for every situation on a busy shop floor, where distractions, fatigue, and pressure to meet deadlines can influence behavior.

Trio Mobil’s operator-assist solutions support operator training in two key ways:

- Access control: Only certified and authorized drivers can operate forklifts. Access is managed through operator badges or tags, preventing untrained or unauthorized personnel from using equipment. This directly supports compliance with OSHA requirements while reducing risks from inexperienced drivers.

- On-vehicle assistive features: Proximity detection, speed control, and AI-powered cameras provide operators with real-time feedback. These alerts reinforce safe driving practices by drawing attention to pedestrians, other forklifts, or risk zones they may not have noticed.

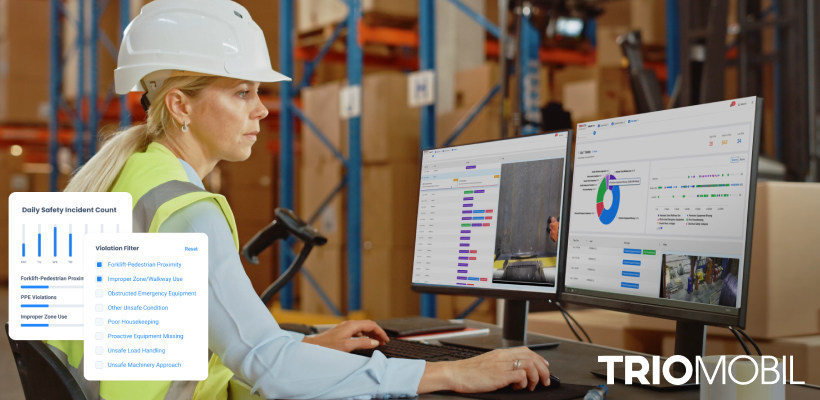

Rule 9: Risk Monitoring - Track and Learn from Incidents

One of OSHA’s core principles for safety management is that organizations should not only respond to accidents but also track and learn from near-misses. Every incident, whether it results in damage or not, provides valuable information about potential hazards. Unfortunately, many facilities underreport or fail to record minor collisions and near-misses. This means patterns go unnoticed until a serious accident occurs.

Trio Mobil’s operator-assist technology adds transparency and reliability to this process with automatic incident tracking. Through impact detection sensors and real-time monitoring, the system records events such as collisions, harsh braking, or sudden impacts. This data is sent to a cloud platform where it can be analyzed alongside other operational metrics.

Key benefits include:

- Objective reporting: Incidents are logged automatically, removing reliance on manual reporting.

- Trend analysis: Managers can identify hotspots or recurring conditions that lead to near-misses.

- Operator feedback: Insights can be used in training sessions to reinforce safe driving practices.

- Continuous improvement: Safety measures can be adjusted based on data rather than assumptions.

Rule 10: Apply Safety Consistently Across Sites

For companies operating multiple warehouses, factories, or distribution centers, consistency is one of the biggest challenges in forklift safety. OSHA standards apply universally, but in practice, each site may have its own layout, culture, and level of risk awareness. A safety program that works well in one facility can lose effectiveness if it isn’t scaled and standardized across the organization.

Inconsistencies often appear in three areas:

- Operator behavior: Some sites may have strong safety cultures, while others cut corners under production pressure.

- Equipment: Forklifts in one facility may be outfitted with safety technologies, while others operate without the same support.

- Reporting and monitoring: Paper-based or local reporting makes it difficult for corporate safety teams to see the big picture across multiple sites.

To overcome these challenges, organizations need solutions that are both modular and scalable. Trio Mobil’s layered safety technology is designed for multi-site rollouts, allowing companies to apply the same layered safety principles consistently.

Features that support standardization include:

- Modular design: Facilities can start with core features like pedestrian detection and speed control, then add AI cameras, lone worker monitoring, or fleet management as needed.

- Cloud-based monitoring: Safety data from every site is centralized, allowing management to compare performance across regions and identify best practices.

- Customizable rules: Each site can configure danger zones, speed limits, and alert thresholds while still adhering to corporate safety policies.

Driving Forklift Safety Forward with Trio Mobil

Forklift safety starts with OSHA’s rules, but technology helps put those rules into practice more effectively. Blind spots, high-traffic areas, and operational pressures will always challenge even the most experienced operators.

That’s why Trio Mobil provides operator-assist solutions designed to support safe decision-making. With AI-powered cameras, pedestrian safety tags, speed control, incident tracking, and lone worker protection, companies can adopt a layered safety approach that reduces near-miss risks and builds a stronger culture of safety.

Whether in a single warehouse or across dozens of sites, Trio Mobil’s modular systems scale easily, helping organizations achieve safer and more productive operations worldwide.

If your goal is to move toward zero accidents and maximum efficiency, get in touch with our team or request a live demo.

Disclaimer: Trio Mobil solutions are operator-assist aids. They do not replace safe working practices or prevent all incidents. Performance depends on operating conditions and configuration; see product documentation.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!