Customizing Forklift Safety Solutions for Different Industries

Forklifts play a pivotal role in various sectors' day-to-day functions. However, the diverse nature of these sectors demands specific safety measures tailored to meet unique environmental challenges and regulatory requirements.

Assessing the industry-specific needs for forklift safety is crucial to complying with legal standards and safeguarding the well-being of operators and other personnel.

This article focuses on the distinctive safety requirements and solutions appropriate for different industries, emphasizing how appropriate safety enhancements can significantly mitigate risks and enhance operational efficiency.

Through a detailed examination of sectors such as manufacturing, warehousing, construction, food and beverage, and chemical and pharmaceutical, we will highlight the integration of advanced technologies and strategic practices in forklift safety management.

Assessing Industry-Specific Needs for Forklift Safety

To effectively minimize risks and enhance efficiency in forklift operations, it is crucial to understand the specific needs and challenges of different industrial environments. Each industry presents unique hazards and operational requirements that can significantly influence the approach to forklift safety.

From the high-traffic manufacturing floors to the tight aisles of warehouses and the rugged terrains of construction sites to the sterile environments of pharmaceutical facilities, custom safety solutions tailored to these distinct settings are essential. By analyzing the specific work conditions and risks associated with each industry, companies can implement the most appropriate safety technologies and practices, maintaining compliance with regulations and supporting the well-being of employees.

Manufacturing

Characteristics of the Manufacturing Industry: High-Volume Production and Material Handling

In manufacturing, forklifts are pivotal in production lines and material handling due to their efficiency in quickly moving heavy and bulky materials. This sector typically features environments with high traffic and fast-moving operations, which necessitate stringent safety measures to prevent accidents commonly associated with forklift operations.

The primary challenges here involve navigating through densely packed spaces, handling materials at high speeds, and maintaining the safety of all personnel on the floor without compromising operational efficiency.

Common Risks:

- Load Drops: Occur during high-speed maneuvers or improper handling, potentially causing injuries or damaging materials.

- Forklift Collisions: Frequent in areas with high forklift traffic, these can result in significant injuries to operators and pedestrians, as well as damage to machinery and infrastructure.

Example Forklift Safety Technologies:

- Advanced Forklift Systems: These systems are equipped with sensors, significantly reducing the risk of human error and increasing the safety and efficiency of operations.

- Forklift Collision Avoidance Systems: These sensors are critical in preventing accidents. They alert forklift operators to potential obstacles or nearby traffic, considerably enhancing reaction times. Integrated with advanced AI cameras, they can detect pedestrians, slowing down the forklifts in case of any risk.

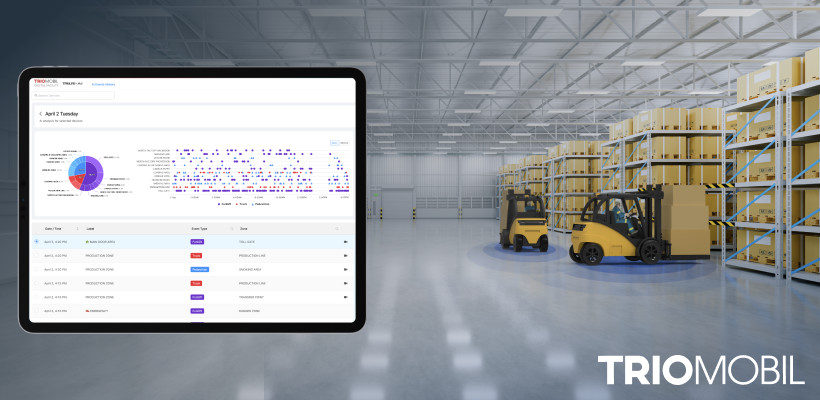

Trio Mobil’s Solutions and Benefits for the Manufacturing Industry

- IoT & AI-based Forklift Safety Systems: Trio Mobil integrates IoT and AI technologies to enhance forklift safety. These systems provide real-time monitoring, predictive analytics, and automated safety measures such as collision avoidance and load stability monitoring. By leveraging advanced AI algorithms, these systems can predict potential safety hazards and suggest proactive measures to prevent accidents, creating a safer and more efficient manufacturing environment.

- Forklift Fleet Management: Trio Mobil’s fleet management solutions offer comprehensive real-time tracking and data analytics for forklift operations. This technology helps in optimizing routes, managing traffic flow, and scheduling maintenance, thus reducing downtime and improving operational efficiency. By continuously monitoring the performance and usage of each forklift, businesses can maintain peak fleet efficiency while upholding high safety standards.

- AGV Safety Systems: Trio Mobil's safety system uses advanced safety measures to prevent collisions between forklifts and AGVs or AMRs. It performs two-stage speed limiting when forklifts are in close proximity to AGVs or AMRs. Provides audible and visual warnings to forklift operators, giving them instant information about the presence of AGVs and AMRs. Instantly activates and intervenes with speed limits to minimize accidents.

Warehousing

Characteristics of the Warehousing Industry: Narrow Aisles, High Shelves

Warehouses are challenging for forklift operations, characterized by narrow aisles and high shelving units. These conditions require precise maneuvering and handling, increasing the risk of accidents.

The primary safety concerns involve avoiding collisions with pedestrians and between forklifts and preventing mishaps due to improper stacking techniques. Securing the safety of forklift operations in these spaces is critical, not only to protect workers but also to preserve the integrity of the goods being handled and the productivity of the warehouse.

Common Risks:

- Pedestrian Collisions: Forklifts operating in close proximity to warehouse staff, especially in narrow aisles, pose a high risk of collisions. These can cause serious injuries to workers and disrupt warehouse operations.

- Forklift Accidents from High-Stacking Errors: Mismanagement in the stacking and retrieving of goods on high shelves can lead to accidents, including forklifts tipping over or loads falling, which pose significant risks to forklift operators and other nearby workers.

Example Forklift Safety Technologies:

- Zone Alert Systems: These systems are essential in warehouses to enhance forklift safety. They notify forklift operators when entering high-risk areas, particularly where pedestrian traffic is present. This system helps mitigate risks by increasing the operator’s awareness of their surroundings.

- Forklift Telematics: This technology involves the use of sensors, GPS, and real-time data to monitor and optimize the movement and operation of forklifts. Telematics can help plan the safest and most efficient routes within the warehouse, manage traffic flow, and significantly reduce the likelihood of accidents by providing operators with crucial information about their immediate environment.

Trio Mobil’s Solutions and Benefits for the Warehousing Industry

- Forklift Collision Avoidance Systems: Equipped with sensors and machine vision technology, Trio Mobil’s collision avoidance systems detect obstacles, other vehicles, and personnel in congested areas. These systems automatically initiate measures to slow down or stop the forklift upon detecting potential hazards, preventing collisions and maintaining safe navigation in tight warehouse spaces.

- Zone Alert Systems: Trio Mobil’s zone alert systems use advanced sensors to create virtual zones within the warehouse. These systems notify forklift operators with audible and visual alerts when they enter high-risk areas, particularly where pedestrian traffic is present. This heightened awareness helps prevent collisions, maintaining the safety of both workers and the goods being handled.

- Forklift Telematics: Trio Mobil’s telematics solutions integrate sensors, GPS, and real-time data to monitor forklift movements and operations continuously. This technology helps plan the safest and most efficient routes within the warehouse, manage traffic flow, and reduce the likelihood of accidents. By providing operators with real-time information about their immediate environment, our telematics systems enhance safety and operational efficiency.

Construction

Characteristics of the Construction Industry: Diverse Environments; Indoors and Outdoors Construction sites are complex environments where forklifts must operate under various conditions, ranging from indoor settings to rugged outdoor landscapes. These sites challenge forklift operations with diverse terrains, varying load types, and the necessity of maneuvering in both confined and open spaces.

Safety in such conditions is paramount, as construction sites' unstable and unpredictable nature heightens the risk of accidents.

Common Risks:

- Uneven Surfaces: Forklifts operating on uneven ground risk tipping over, especially when carrying heavy loads. These surfaces can greatly destabilize forklift operations, endangering the operator and other workers on site.

- Varied Load Types: Construction materials vary significantly in size, weight, and stability. Handling these varied loads requires highly adaptable forklifts and operators well-trained in diverse operational techniques.

Example Forklift Safety Technologies:

- Zone-Based Forklift Speed Control: This safety feature automatically adjusts the speed of the forklift depending on the zone it enters within a construction site. Sensitive areas, such as those with uneven terrain or high pedestrian traffic, will trigger the system to reduce speed, significantly lowering the risk of accidents.

- Forklift Tracking Systems: Utilizing GPS and real-time monitoring software, this technology provides a comprehensive overview of forklift movements and behavior across the construction site. Monitoring forklift locations, travel speeds, and operational patterns helps prevent collisions and promote efficient equipment use.

Trio Mobil’s Solutions and Benefits for the Construction Industry

- Collision Avoidance Systems: Trio Mobil uses high-precision Ultra-WideBand (UWB) technology to detect obstacles, maintaining safe operation on uneven terrains typical of construction sites. This system alerts operators to potential hazards, preventing accidents and protecting workers navigating diverse and unpredictable environments.

- Telematics Systems: Our real-time monitoring and predictive analytics are crucial in construction settings, where varied load types and challenging terrains are common. These systems enable proactive maintenance and optimal route planning, reducing risks associated with unstable loads and enhancing operational efficiency by providing data-driven insights tailored to construction site needs.

- Zone-Based Speed Control: This technology is particularly beneficial in construction zones with high pedestrian traffic or uneven terrain. By automatically adjusting forklift speed in these high-risk areas, we prevent accidents and maintain safe operation, addressing the unique safety challenges of the construction industry.

- Comprehensive Tracking Solutions: Utilizing GPS and real-time monitoring software, Trio Mobil’s solutions provide detailed insights into forklift movements and behaviors across construction sites. This continuous tracking and analysis help prevent collisions, promote efficient equipment use, and adapt to the dynamic nature of construction environments.

Food & Beverage

Characteristics of the Food & Beverage Industry: Environment Constraints; Cold Storage, Washdown Areas

The food and beverage industry frequently operates in environments that pose significant challenges to standard forklift operations, such as cold storage areas and washdown zones. These conditions necessitate specific safety adaptations for forklifts to handle extreme temperatures and wet conditions without compromising operational integrity or safety.

Common Risks:

- Slippery Surfaces: Common in washdown areas, slippery surfaces can significantly increase the risk of forklift accidents, leading to potential control issues and collisions.

- Mechanical Degradation: Operating in harsh environments, especially in cold storage areas, can rapidly degrade mechanical components, affecting the performance and reliability of forklifts.

Example Forklift Safety Technologies:

- Pre-ops Safety Checklist: This crucial safety protocol requires operators to perform a detailed manual inspection of the forklift before commencing operations each day, especially vital in the food and beverage industry where conditions such as cold and wet environments can significantly affect machinery performance.

- Impact Detection System: This system incorporates forklift sensors to detect and log any impacts or near-miss events. Such systems are essential in the challenging environments of the food and beverage industry, where slippery surfaces and potential obstructions are common. They alert operators and management in real time to potential dangers, assisting in preventing accidents and contributing to long-term safety enhancements through data analysis, which can identify common operational errors or problematic areas.

Trio Mobil’s Solutions and Benefits for the Food & Beverage Industry

- Pre-ops Safety Checklist: Trio Mobil provides digital pre-ops safety checklists that operators can easily complete before starting their shifts. This system keeps forklifts in optimal condition to handle the specific challenges of cold and wet environments, thereby preventing mechanical failures and maintaining safe operations.

- Impact Detection System: Trio Mobil’s impact detection systems are equipped with sensors that detect and log any impacts or near-miss events in real-time. This technology is particularly useful in slippery and obstruction-prone areas of the food and beverage industry. The system alerts operators and management to potential dangers immediately, helping to prevent accidents and facilitating data-driven safety improvements by identifying frequent operational errors and high-risk areas.

Chemical & Pharmaceutical

Characteristics of the Chemical & Pharmaceutical Industry: High Standards for Precision and Contamination Prevention

In the chemical and pharmaceutical sectors, handling and transporting materials require the highest levels of precision and safety due to the potential risks associated with contamination and exposure to hazardous substances.

Forklifts in these industries are specially equipped to meet stringent standards, maintaining adherence to strict regulatory compliance requirements while preventing any risk of contamination.

Common Risks:

- Exposure to Hazardous Materials: Forklift operators and other workers must be shielded from potentially dangerous chemical exposures, which can occur from spills, leaks, or the mishandling of volatile substances.

- Strict Regulations: These industries are heavily regulated for safety and efficacy, necessitating compliance with rigorous operational protocols to avoid severe penalties.

Example Forklift Safety Technologies:

- Forklift Tracking & Monitoring Systems: These systems are essential in environments dealing with chemicals and pharmaceuticals, where precision is critical. Equipped with GPS and real-time monitoring capabilities, these systems track forklift movements and monitor operator behavior to maintain adherence to safety protocols.

- Forklift Collision Avoidance Systems: Specifically designed to prevent accidents in tight and congested areas, these systems use sensors and machine vision technologies to detect obstacles, other vehicles, and personnel. Upon detection, the system automatically initiates measures to slow down or stop the forklift, thereby preventing collisions. This is particularly important in the chemical and pharmaceutical industries, where even minor accidents can lead to serious safety incidents or contamination risks.

Trio Mobil’s Solutions and Benefits for the Food & Beverage Industry

- Pre-ops Safety Checklist: Trio Mobil provides digital pre-ops safety checklists that operators can easily complete before starting their shifts. This system keeps forklifts in optimal condition to handle the specific challenges of cold and wet environments, thereby preventing mechanical failures and supporting safe operations.

- Impact Detection System: Trio Mobil’s impact detection systems are equipped with sensors that detect and log any impacts or near-miss events in real-time. This technology is particularly useful in slippery and obstruction-prone areas of the food and beverage industry. The system alerts operators and management to potential dangers immediately, helping to prevent accidents and facilitating data-driven safety improvements by identifying frequent operational errors and high-risk areas.

Advancing Forklift Safety with Trio Mobil's Innovative Solutions

Forklift safety is a complex and vital aspect of modern industrial operations, requiring tailored approaches to adequately address the unique environments and challenges of various industries. From the high-traffic areas of manufacturing facilities to the precise and contamination-sensitive environments of pharmaceutical production, each industrial setting demands specialized solutions to safeguard operators and maintain the efficacy of operations. Integrating advanced technologies such as collision avoidance systems, forklift telematics, and automated safety protocols reflects the industry's shift towards more sophisticated, preventative safety measures.

By leveraging Trio Mobil's innovative safety solutions, businesses can significantly enhance their forklift safety standards. Trio Mobil's advanced systems, including real-time monitoring and analytics, provide comprehensive oversight of forklift operations, helping to prevent accidents before they occur and maintain compliance with stringent safety regulations.

As industries continue to grow and evolve, the emphasis on adaptive and integrated safety solutions becomes even more crucial. Trio Mobil remains at the forefront of this initiative, constantly developing new technologies and systems to meet the ever-changing demands of workplace safety. This commitment enhances operational efficiency and solidifies a company’s reputation for reliability and employee care.

For more detailed information about our cutting-edge, modular, plug-and-play solutions, browse our website or request a demo to see how our forklift safety system works.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!