Workplace safety has steadily improved over the years, with many organizations lowering recordable incident rates. Yet Serious Injuries and Fatalities (SIFs) remain a stubborn challenge. Unlike minor incidents, these events carry irreversible consequences for workers, families, and companies.

Research by the Campbell Institute highlights that up to 20% of recordable incidents have the potential to result in a SIF. This demonstrates why focusing on SIF prevention is vital: Minor injuries may be reduced, but the most severe outcomes demand greater attention.

For EHS leaders, preventing SIFs is not just about compliance. It is a moral responsibility, a business necessity, and a cornerstone of operational resilience.

The Leading Causes of SIFs in Industrial Operations

Industrial facilities such as warehouses, production plants, and logistics hubs present complex environments where multiple risks overlap. The most common causes of SIFs include:

- Forklift - pedestrian collisions in high-traffic zones

- Loading-dock accidents linked to blind spots or unstable cargo

- Unsafe lifting or stacking practices that reduce visibility or stability

- Human error, such as speeding, harsh braking, or distracted driving

These incidents often share a common trait: they are preceded by observable precursors such as near misses, close calls, or unsafe conditions. Unfortunately, many of these signals are either underreported or invisible in daily operations, leaving safety managers without the data they need to act in time.

Building on Traditional Approaches to SIF Prevention

Organizations rely on proven methods to lower risk:

- Training programs reinforce safe practices and awareness.

- Audits and inspections uncover hazards and compliance gaps.

- Near-miss reporting systems capture warning signs before escalation.

- Engineering controls like mirrors, barriers, and signage guide safer traffic flows.

Alongside these, technology-driven safety solutions add an additional layer of protection:

- AI-powered pedestrian detection recognizes people in blind spots, including untagged visitors and contractors.

- UWB proximity detection enables ultra-precise distance measurement between forklifts and pedestrians, delivering real-time alerts and automatic interventions to help reduce risks in blind-spots and near-miss incidents.

- Real-time Collision Avoidance systems continuously monitor the environment around moving equipment, automatically warning operators and slowing or stopping vehicles when a potential collision is detected.

- Zone-based speed control automatically slows forklifts in high-risk areas such as intersections or loading docks.

- Unified safety networks connect forklifts, AGVs, and pedestrians, creating coordinated alerts to prevent collisions.

- Fleet-wide monitoring and analytics consolidate driving data, zone activity, and incident history to identify high-risk patterns.

- Lone worker monitoring uses motion-sensitive tags to detect inactivity, alerting supervisors if an employee becomes unresponsive.

These solutions collectively strengthen SIF prevention efforts. But because they often operate separately, leaders may lack a consolidated, real-time view of SIF exposure. This is where an integrated layer of intelligence makes the difference.

For a deeper understanding of the risks behind SIFs and how they can be proactively addressed in forklift operations, explore our blog: What is SIF Prevention and Why is it Critical in Forklift Operations.

From Forklift Safety to SIF Prevention: Trio Mobil’s Approach

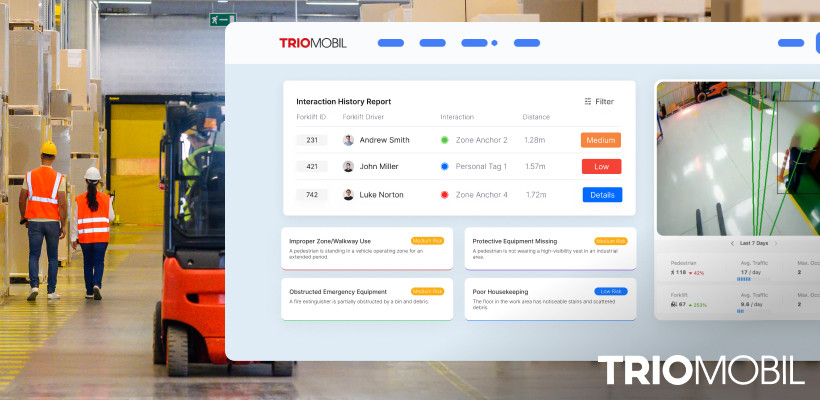

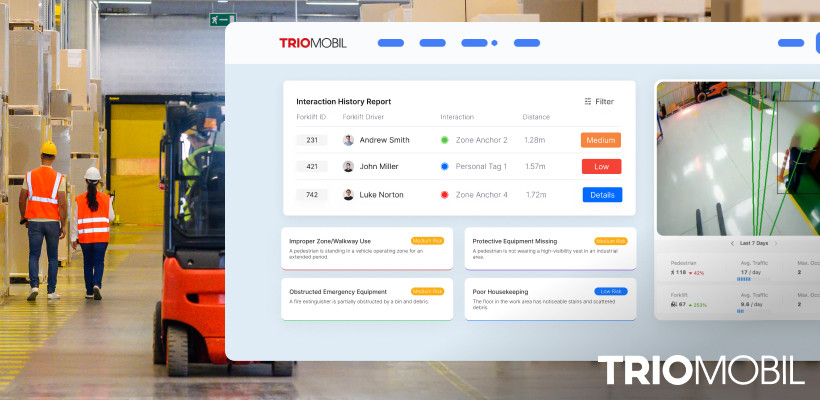

At Trio Mobil, our safety solutions are built to assist trained operators and EHS teams in managing high-consequence risks. Each system in our platform contributes to preventing Serious Injuries and Fatalities by addressing the conditions where they are most likely to occur:

- TRIO SAFE AI – Layered Forklift and Pedestrian Safety: Creates a 360° detection field around forklifts and provides directional alerts to operators when pedestrians or vehicles enter critical proximity. This directly addresses one of the leading causes of SIFs: blind-zone pedestrian interactions. The system supports both tagless AI-based detection and UWB tag-based proximity alerts, allowing flexible deployment across diverse operational environments.

- UWB Proximity Detection: A tag-based solution that utilizes high-precision ultra-wideband technology to measure precise distance between forklifts, AGVs, and pedestrians, triggering tiered visual and audible alerts - or even automatic interventions - to help prevent near-miss incidents and enhance situational awareness in dynamic work zones.

- Real-Time Collision Avoidance: Integrates AI and proximity data to continuously monitor vehicle surroundings, automatically warning operators and initiating speed reduction or controlled stops when potential collisions are detected.

- Zone Controls: Automatically slows forklifts in predefined danger areas such as intersections, loading docks, or congested aisles. This reduces operator variability and enforces consistent compliance where speed control matters most.

- Forklift Fleet Monitoring and Analytics: Consolidates vehicle and zone data into a single platform, allowing safety teams to review incidents, detect patterns, and refine safety strategies with data-driven insights.

- Lone Worker Safety: Uses motion-sensitive tags to detect inactivity in low-traffic or isolated areas, sending immediate alerts to supervisors if a worker becomes unresponsive. This provides timely assistance in situations that might otherwise go unnoticed.

Together, these systems form a layered defense against SIFs, addressing known risk scenarios and building a foundation for safer operations.

AI Risk Radar: Extending Prevention Through Real-Time Intelligence

While Trio Mobil’s forklift safety systems target specific, high-risk conditions, AI Risk Radar expands prevention efforts across the entire facility. Acting as a 24/7 digital EHS inspector, it continuously monitors for more than 100 risk scenarios, from forklift interactions to general workplace hazards.

AI Risk Radar provides:

- Real-time detection of SIF precursors such as pedestrian–forklift near misses, blind-spot hazards, unsafe load handling, or distracted driving.

- Quantifiable risk scoring, assigning a measurable index to each unsafe event (e.g., “Top 10 forklifts with the highest SIF risk exposure this week”).

- Immediate interventions through automated alerts, such as lights, sounds, or automatic slowdowns, to stop unsafe behaviours before they escalate.

- Flashback replay for audits and investigations, enabling quick access to video evidence.

- Safety CoPilot integration, allowing leaders to ask questions (“Show last quarter’s forklift near misses”), run deep risk analysis, and receive AI-driven recommendations for corrective actions.

By complementing solutions like TRIO SAFE AI, Zone Controls, Fleet Monitoring, and Lone Worker Safety, AI Risk Radar brings everything into one continuous, proactive safety framework.

How AI Risk Radar Translates Safety into Measurable Outcomes

Translating risk insights into tangible safety gains is where AI Risk Radar stands apart. Unlike traditional safety systems that often react after the fact, this solution transforms real-time observations into immediate, measurable action. By embedding advanced AI intelligence into daily operations, organizations can proactively reduce incidents, optimize workflows, and foster a data-driven culture of prevention. What was once anecdotal or manually observed becomes continuously monitored, quantified, and actionable, which allows EHS teams to focus on solving the right problems before they escalate:

Reduced incidents through proactive risk detection

AI Risk Radar continuously monitors for unsafe conditions, detecting precursors such as near misses, blind-spot risks, or speeding before they escalate. This early intervention lowers the likelihood of serious events, helping address risks at their source rather than after an incident occurs.

A stronger safety culture supported by continuous monitoring

When employees know that risks are being monitored objectively and fairly, safety becomes a shared responsibility. AI-driven insights reinforce awareness, encourage safer behaviors, and help establish a culture where prevention is prioritized at every level of the organization.

Objective compliance support with verifiable data and video evidence

Instead of relying solely on manual reports or observations, AI Risk Radar provides documented, timestamped evidence of safety events. This strengthens compliance efforts, simplifies regulatory reporting, and gives leaders confidence that their safety performance is backed by reliable data.

Proactive prevention that addresses risks before escalation

The system identifies unsafe patterns in real time — whether it’s repeated zone violations, recurring pedestrian–forklift interactions, or unsafe vehicle handling. By catching these issues early, EHS teams can intervene with corrective actions before they evolve into high-consequence incidents.

Improved operational efficiency by aligning safety with workflow

AI Risk Radar not only reduces risk but also supports smoother operations. By minimizing disruptions caused by near misses and unsafe practices, the system helps improve throughput, maintain productivity, and balance safety with efficiency in day-to-day workflows.

Taking the Next Step in SIF Prevention with Trio Mobil’s AI Risk Radar

Serious Injuries and Fatalities remain one of the most pressing challenges in industrial safety. Traditional approaches and Trio Mobil’s core forklift safety systems provide essential protection, but organizations need an additional layer of intelligence to unify data and capture hidden precursors.

AI Risk Radar strengthens these efforts by continuously monitoring facilities, detecting unseen risks, and delivering real-time intelligence to EHS leaders.

By making hidden risks visible and actionable, organizations can take the next step in SIF prevention - protecting their workforce, providing compliance, and driving safer operations.

To discover how Trio Mobil’s AI Risk Radar can help you strengthen SIF prevention with proactive, real-time risk intelligence, get in touch with our team for a free safety consultancy.