How AI-Powered Risk Monitoring Reduces High-Risk Events in Industrial Operations

Industrial operations are becoming more complex every year. Forklifts, pedestrians, contractors and automated systems move simultaneously through shared spaces, creating a constantly shifting safety landscape. Even the most dedicated EHS teams cannot watch every corner of a facility at all times, which means many high-risk behaviors and near-misses occur without being documented or addressed.

Traditional safety methods rely on manual observation, periodic audits and after-the-fact reporting. These practices remain essential, yet they often leave important gaps, especially when risks occur in seconds. Repeated unsafe behaviors, missed near-misses and visibility limitations can contribute to serious incidents that might have been avoidable with earlier awareness.

AI-powered risk monitoring provides an important step forward. Trio Mobil’s AI Risk Radar™ transforms existing forklift cameras, TRUE AI cameras and CCTV systems into a continuous source of safety intelligence. It analyzes workplace activity in real time and identifies unsafe behaviors the moment they occur, supporting EHS teams with timely insights. This approach strengthens safety programs by providing consistent 24/7 visibility across the entire facility.

Why High-Risk Events Require a Different Approach

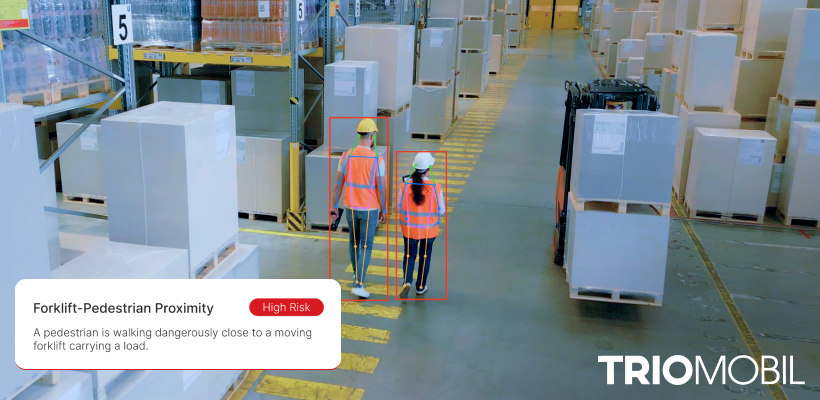

High-risk events in industrial environments often occur within seconds and can carry Serious Injury and Fatality (SIF) potential. Risks such as forklift and pedestrian proximity, unsafe work at height or distracted vehicle operation frequently develop too quickly for traditional observation methods to capture. Manual supervision, scheduled audits and incident reporting remain important, but they cannot provide full visibility in fast-moving operations where many unsafe actions go unreported or unseen.

These visibility gaps make it difficult for EHS teams to understand how often high-risk behaviors occur or which zones contribute most to SIF potential. As a result, corrective actions may be delayed or based on incomplete information. A more effective approach is real-time detection supported by AI, which highlights risks the moment they appear and helps teams focus their attention where it has the greatest impact.

This approach provides:

- Immediate identification of unsafe behaviors

- Automatic High, Medium or Low severity classification

- Clear visual evidence for faster investigation

- Continuous insight into recurring patterns and high-risk zones

Introducing AI Risk Radar

Trio Mobil developed AI Risk Radar to give EHS teams continuous support in environments where risks can appear in seconds. It expands Trio Mobil’s operator-assist ecosystem by turning existing forklift cameras and facility CCTV systems into real-time safety sensors that help teams identify unsafe conditions earlier and focus their attention on the zones and behaviors with the highest impact.

A Continuous Digital EHS Inspector

AI Risk Radar operates on top of existing video infrastructure, including:

- Forklift-mounted cameras

- CCTV and IP cameras

- Production line and machine-cell cameras

This allows facilities to modernize their safety approach without major hardware replacement.

Proactive Risk Identification

The system continuously identifies potential safety risks before they escalate into incidents. Instead of triggering last-minute interventions, it enables teams to take timely and informed precautions, reducing the need for urgent corrective actions.

- Identifying early risk indicators that require preventive measures

- Highlighting recurring unsafe patterns to support long-term improvement

- Improving visibility in high-activity or hard-to-monitor areas to address risks in advance

This approach allows organizations to manage hazards, such as fire risks, at an early stage by implementing necessary controls before an incident occurs, rather than responding after it has already started.

Designed for High-Risk Environments

AI Risk Radar monitors a broad range of risk categories, which helps teams focus on the conditions with the highest safety impact. The system functions as an operator-assist tool that enhances, rather than replaces, established safe practices.

High-Risk vs. Medium-Risk vs. Low-Risk Severity Classification

Safety programs become more effective when every detected event is classified by its potential impact. AI Risk Radar supports EHS teams by assigning a severity score to each unsafe condition. This helps organizations focus on high-priority risks first and understand where SIF potential is the highest.

Below is a structured view of how severity levels can be classified in real time:

| Severity Level | Typical Event Types | Why It Matters |

|---|---|---|

| High Risk | - Forklift and pedestrian proximity - Mobile phone use during vehicle operation - Entering restricted zones - Unsafe work at height - Interaction near active machinery - Smoking in unauthorized areas |

High probability of serious injury. These events require immediate attention and rapid investigation. |

| Medium Risk | - PPE non-compliance - Walking outside designated paths - Minor unsafe load handling - Housekeeping issues in active areas |

Lower immediate danger but can escalate. Medium risks often appear more frequently and indicate systemic gaps. |

| Low Risk | - Minor behavioral deviations in low-activity areas - Situations with low SIF potential - Non-critical zone violations |

Useful for understanding habits and early patterns before they escalate into higher-risk actions. |

Why Severity-Based Scoring Helps

- EHS teams can prioritize daily reviews based on impact.

- High-risk alerts trigger faster corrective action workflows.

- Repeated medium-risk events help identify unsafe trends.

- Low-risk events provide early indicators of cultural or procedural gaps.

- Supervisors gain a more balanced view of safety performance across shifts and zones.

AI Risk Radar’s Expanding Vision Library

AI Risk Radar continuously analyzes workplace activity and identifies more than one hundred unsafe conditions. These detections help EHS teams understand where high-risk behaviors occur, how often they appear and which patterns may contribute to SIF potential. The system adapts to different facility layouts and operating conditions, allowing coverage to expand as needs evolve.

Key risk types monitored include:

- Protective equipment missing such as helmets, vests, and disabled safety devices, which often indicate cultural or procedural gaps.

- Smoking in unauthorized areas including production floors, warehouses, or near flammable materials, which introduces fire and explosion risk and often reflects procedural non compliance.

- Mobile phone usage in operational areas including walking, operating equipment, or working near moving vehicles, which reduces situational awareness and increases distraction related risk.

- Improper zone or walkway use including pedestrians leaving designated paths, entering restricted areas or blocking exits, which increases the likelihood of forklift and pedestrian interactions.

- Unsafe load handling and stacking such as overloaded pallets, unstable stacks or unsafe transport positions, which raise the risk of drops and tip-overs.

- Obstructed emergency equipment including blocked fire extinguishers, covered first aid stations or inaccessible evacuation routes, which can delay response during critical moments.

- Poor housekeeping such as spills, debris, cluttered aisles or improperly stored tools, which contribute to slips, falls and vehicle instability.

- Forklift and pedestrian proximity including close interactions, poor visibility situations and unexpected crossings in intersections or dock areas, all of which carry strong SIF potential.

- Other unsafe behaviors such as entering active machinery zones or working with low visibility, which can escalate quickly when combined with other risks.

- Unsafe vehicle operation because of mobile phone use, which is a major contributor to severe incidents.

GDPR-Compliant, Ethical AI for Modern Safety Programs

AI-powered monitoring must support safety without compromising employee privacy. AI Risk Radar is designed to operate responsibly and follow GDPR and other data protection standards. The system provides several privacy-focused features that help organizations create safer operations while maintaining ethical data practices.

Key privacy and compliance features include:

- Optional face and body blurring: Blurring can be applied automatically to protect personal identity while preserving safety insights.

- Controlled access to video evidence: Only authorized personnel can view relevant footage, and access logs can be managed centrally.

- Configurable retention periods: Video and event clips can be stored for limited durations depending on internal policies and regional regulations.

- Data used only for safety improvement: AI Risk Radar supports operator awareness and EHS workflows without being used to measure personal performance.

- Compliance with GDPR requirements: The system supports transparency, purpose limitation and secure handling of all recorded safety events.

- An ethical AI approach: Designed to highlight risks and support safer decision-making without creating intrusive monitoring practices.

Transforming Existing Forklift Cameras and CCTV Streams into Smart Safety Sensors

Many facilities already have extensive camera infrastructure, including forklift-mounted cameras, CCTV systems and IP-based video networks. AI Risk Radar allows organizations to use these existing video sources to gain real-time visibility into unsafe behaviors. This eliminates the need for large hardware replacements and makes AI-powered monitoring easier to adopt.

Key capabilities include:

- Compatibility with forklift cameras: Existing camera views can be analyzed to detect proximity risks and visibility-related hazards.

- Integration with CCTV and IP cameras: Facility-wide video systems become continuous safety sensors without needing new installation.

- Instant analysis of live video feeds: AI identifies unsafe events in real time and supports faster awareness and response across high-traffic zones.

- Cost-effective modernization: Organizations can upgrade their safety visibility using the infrastructure they already have.

- Scalable across multiple sites: New locations can be onboarded quickly by connecting their existing cameras to the AI Risk Radar ecosystem.

- Supports hybrid camera environments: Analog-to-digital conversions, mixed brands and older models can still contribute to AI-powered monitoring.

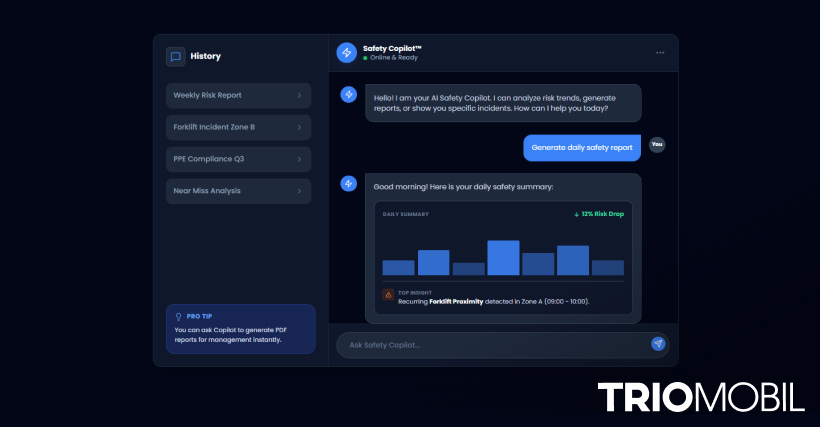

Turning Data Into Safety Intelligence With Safety Copilot

AI Risk Radar generates continuous visibility, but the real value comes from transforming that information into practical insights. Safety Copilot helps EHS teams interpret large volumes of event data without navigating complex dashboards or manual reports. It acts as an AI assistant that supports faster decision-making and deeper understanding of safety performance.

Key capabilities include:

- Instant answers to safety questions: Teams can ask about near-miss trends, risk categories, or specific behaviors and receive direct, data-backed responses.

- Root cause discovery: AI highlights patterns that contribute to repeated unsafe conditions, revealing where deeper investigation may be needed.

- Identification of emerging hazards: Early warning signals help teams detect new types of unsafe behavior or zones that are becoming high-risk.

- Smart recommendations for improvement: The system proposes practical steps that can help reduce recurring risks and strengthen safety culture.

- Simplified interpretation of complex metrics: Safety data is translated into clear language that can be shared across teams and leadership.

- Support for SIF-focused analysis: High-risk events are summarized with context to help prioritize actions that reduce SIF potential.

- Greater team empowerment: Every EHS professional gains an intelligent tool that expands analytical capacity without adding workload.

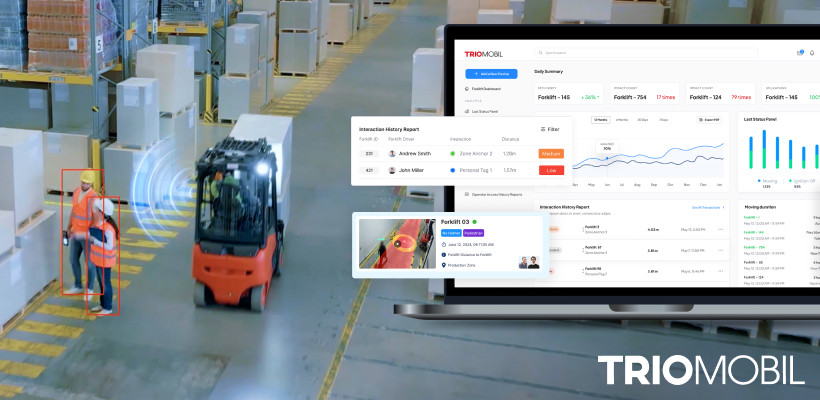

AI Risk Center Dashboard: From Insight to Action

AI-powered monitoring becomes most effective when insights can be acted on immediately. The AI Risk Center Dashboard brings all captured events, severity alerts and risk trends into one place. It supports faster investigations, clearer communication and more efficient corrective actions across the facility.

Key capabilities include:

- Real-time severity alerts: High, medium and low-risk events trigger instant notifications through SMS, email, mobile apps or connected beacons.

- One-click flashback replay: Short video clips provide immediate visual context for investigations, coaching or incident follow-up.

- Centralized event timeline: All detected risks appear in chronological order, helping teams understand when and where issues are occurring.

- Risk trend analytics: Recurring events can be reviewed by shift, zone or facility to identify patterns that may contribute to SIF potential.

- Simplified compliance reporting: Event logs, video evidence and analytics can be exported quickly for internal reviews or regulatory documentation.

- Support for faster corrective actions: Teams can assign tasks, track progress and reduce the time needed to address safety gaps.

- Visibility across multiple sites: Facilities within the same organization can be monitored from a unified view for consistent safety oversight.

Driving Safer Industrial Operations With Trio Mobil’s AI Risk Radar

AI-powered risk monitoring is becoming an essential component of modern safety programs. Facilities are more dynamic than ever, and traditional observation methods cannot always capture every high-risk moment. Trio Mobil supports this shift by providing continuous visibility, timely alerts and data-driven insights that help EHS teams focus on risks with the highest impact.

AI Risk Radar strengthens existing safety practices by analyzing camera streams in real time and highlighting unsafe behaviors as they occur. Safety Copilot adds a layer of intelligence that turns this information into meaningful guidance, helping teams understand root causes, recurring patterns and emerging hazards. Together, these tools create a scalable approach that supports safer operations across single facilities or multi-site organizations.

For organizations aiming to reduce high-risk events and strengthen safety culture, AI-powered monitoring provides a practical and proactive path forward. Trio Mobil is ready to help you explore what this can look like in your own environment. Contact our team to schedule a short executive briefing and see how AI can support your safety goals.

Disclaimer: Trio Mobil solutions are operator-assist aids. They do not replace safe working practices or prevent all incidents. Performance depends on operating conditions and configuration.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!