Artificial intelligence is now widely discussed in industrial safety.

Many organizations claim to be “using AI.” Far fewer have institutionalized it in a way that meaningfully changes safety outcomes.

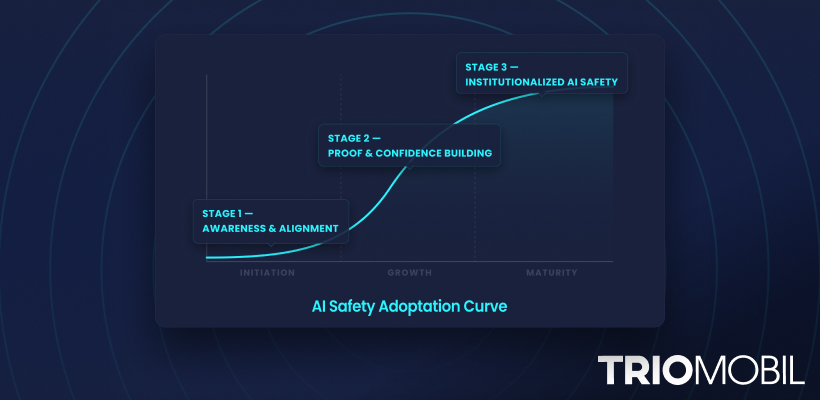

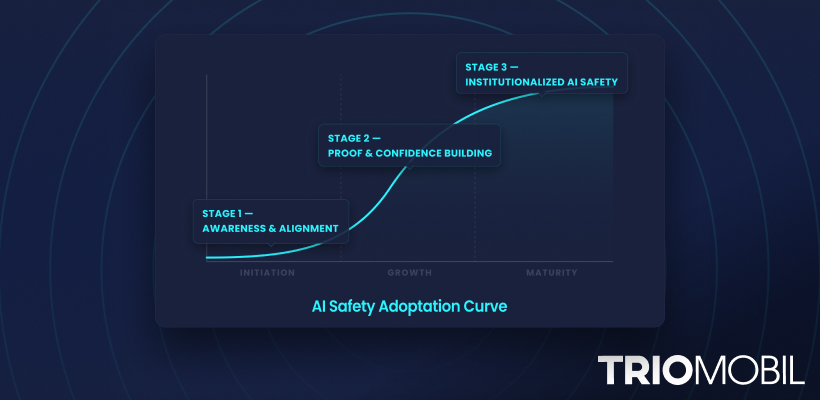

Based on our work with global manufacturing and logistics organizations at Trio Mobil, we consistently observe a clear AI Safety Adoption Curve with three distinct stages. Understanding where your organization sits on this curve is critical—not for technology selection, but for decision-making, governance, and risk reduction.

Stage 1: Awareness & Alignment

At this stage, AI is understood conceptually.

Leadership recognizes its potential, but operational ownership is still unclear.

Common characteristics include:

- AI discussed primarily at a strategic or exploratory level

- Misalignment across Safety, Operations, and IT

- Safety performance still measured reactively, based on incidents rather than exposure

Organizations in Stage 1 are not failing—they are preparing. However, no material safety decisions have changed yet.

Stage 2: Proof & Confidence Building

Stage 2 begins when AI moves from theory into real operating environments.

Typical indicators:

- Pilot deployments at selected sites

- Active evaluation of data quality and operational fit

- Early confidence building, coupled with cautious decision-making

This stage is often where progress slows.

Pilots demonstrate technical feasibility, but organizational uncertainty remains.

Importantly, the challenge here is rarely AI model accuracy. In practice, the real constraints are:

- Governance: Who owns AI-driven safety decisions?

- Ownership: Is AI a safety tool, an IT system, or an operations control?

- Decision velocity: How quickly insights translate into action

Many organizations stall in Stage 2—not because AI fails, but because the operating model does not evolve.

Stage 3: Institutionalized AI Safety

Institutionalization occurs when AI becomes part of the safety operating model, not an isolated tool.

Organizations at this stage show clear signals:

- AI insights influence daily and weekly safety decisions

- Risk prioritization is exposure-based, not incident-based

- Roll-outs are centrally governed with local accountability

At this point, AI no longer supports safety—it shapes how safety is managed.

What AI Actually Adds to Safety Programs

AI’s true value in industrial safety is often misunderstood.

It is not automation for its own sake.

It is not dashboards or alerts in isolation.

What AI fundamentally adds is:

- Continuous visibility into high-risk exposure

- A closed feedback loop between risk detection and intervention

- The ability to move safety from reactive to optimized and decision-driven

This shift is what enables organizations to progress from pilots to institutionalization.

A Reality Check for Multi-Site Organizations

Most large organizations do not sit in a single stage.

Different sites often occupy different points on the curve simultaneously.

This is normal.

The more important question is not:

“Are we using AI?”

It is:

“Which safety decisions change because of it?”

When AI changes how speed limits are enforced, how layouts are adjusted, how shifts are governed, or how risk is prioritized—then adoption is real.

Moving Forward: Technology vs. Operating Model

Successful AI safety adoption is not about technology alone.

It is about designing the operating model around that technology.

Organizations that scale AI successfully:

- Define decision ownership early

- Integrate AI outputs into existing safety governance

- Treat AI as infrastructure for risk reduction, not an experiment

The result is not just better visibility—but sustained, systemic improvement in safety performance.

Final Thought

AI adoption in industrial safety follows a predictable curve.

Technology enables progress—but institutionalization determines impact.

Understanding where you are on that curve is the first step toward changing what matters most: how safety decisions are made, every day.