Protecting Employees and Creating Safer Workplaces: Leveraging Smart Safety Systems

Today’s safety leaders recognize the transformative potential of advanced technologies in reducing incidents, promoting safety excellence, and fostering healthier workplaces. Throughout my three decade career in workplace safety, which includes serving as the Chair of the U.S. Occupational Safety and Health Review Commission (OSHRC) and as Vice President of Worldwide Workplace Safety at one of the world’s largest companies, I have navigated regulatory compliance and championed proactive safety. I offer the following insights on the state of innovative technologies in workplace safety and explore how smart safety systems can create safer, more engaging environments for employees, including the innovative solutions of Trio Mobil.

The State of Workplace Health and Safety

For decades, workplace safety focused primarily on regulatory compliance and tracking all workplace incidents and injuries. This traditional approach to safety often focuses on preventing or minimizing human errors or mistakes. However, the perspective is shifting as organizations recognize that, collectively, we have plateaued in our efforts to reduce Serious Incidents and Illnesses (SIF)—a incident metric which the National Safety Council broadly defines as “injuries, illnesses, process safety events, environmental hazards/exposures, fire, and property damage” and includes near misses or potential SIFs (pSIFs). (See NSC Prevention Model at https://www.nsc.org/workplace/sif-prevention-model)

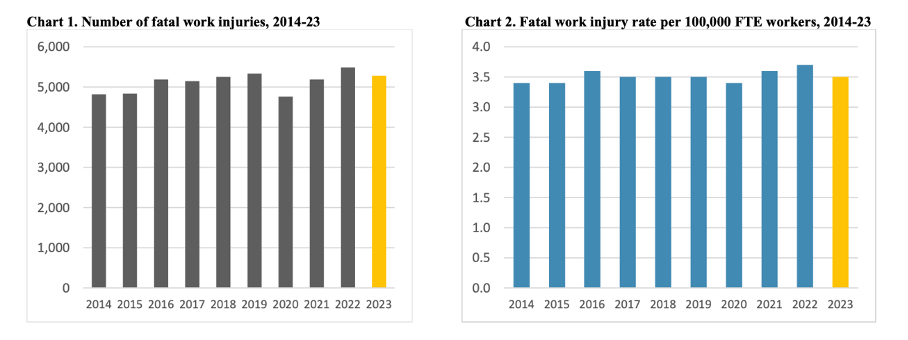

The data shows that there is still much work to do in eliminating life-changing workplace incidents. In December 2024, the U.S. Bureau of Labor Statistics (BLS) reported that there were 5,283 fatal work injuries recorded in the United States in 2023. The fatal work injury rate was 3.5 fatalities per 100,000 full-time equivalent (FTE) workers. As reported by BLS in its December press release while the U.S. saw a year-over-year decrease in fatal work injuries in 2023, significant process has not been achieved over the span of the past decade:

As a result, the focus of workplace safety cannot be just about meeting compliance standards or seeking to minimize human errors or mistakes: A targeted approach must build safety capacity to address the hazards and conditions in operations and creating barriers and controls against them.

Industries like manufacturing, warehousing, and logistics experience disproportionately high rates of accidents. High-risk environments, such as those involving heavy machinery and intricate workflows, present unique challenges in maintaining both efficiency and safety.

OSHA estimates that nearly 100,000 forklift injuries and about 85 fatalities occur each year in the United States. In fact, of the over 856,000 forklifts in use in the U.S., over 10 per cent are involved in an accident, annually.

To look at safety differently than the traditional approach focused on preventing or minimizing human errors or mistakes, an approach often called Human and Organizational Performance (‘HOP”) has evolved over the past decade or so. HOP examines the interaction between people; work systems; equipment; and the environment. HOP focuses on human and organizational weaknesses that lead to errors and mistakes, and it recognizes that we cannot eliminate all errors or mistakes from a system that involves humans. HOP focuses on the presence of safeguards or safety controls that can prevent SIFs, even when a person makes an error or mistake. This concept is known as “capacity”—a system of controls that enables the worker to “fail safely” when an error or mistake is made.

When employees work in conditions lacking in organization or operational capacity, psychological safety is also undermined. Psychological safety refers to a collective belief within a team or organization that individuals can openly share their thoughts, ideas, concerns, and mistakes without the risk of embarrassment, punishment, or adverse consequences. It cultivates a culture of trust, respect, and transparent communication, empowering employees to take risks, contribute freely, and collaborate effectively without fear of judgment. Unsafe environments also contribute to elevated stress levels, reduced morale, and lower job satisfaction.

All of this underscores the need for a proactive approach to workplace safety—one that sets an organization’s shared sense of purpose of ensuring everyone’s well-being and the recognition that every role in an organization is just as important and supports an environment for learning and the capacity for safety. A proactive approach to safety also thinks about the presence of safeguards or safety controls that can prevent serious incidents, even when a person makes an error or mistake.

The Role of Technology in Transforming Workplace Safety

To continually improve and flourish, business and safety leaders need to explore new ways of operating and approaching safety innovations with curiosity and critical thinking. With regulatory and operational environments becoming more complex, technology plays a critical role in enhancing workplace safety and reducing the risks associated with human error. Within this new territory, I am excited about the possibilities.

Proactive safety measures increasingly rely on advanced technologies, like IoT and AI, to address risks before they result in accidents. We can harness these to influence an organizational culture that values safety and to drive positive safety results.

Undoubtedly, technology has dramatically changed the way businesses operate, and its impact on workplace safety is no exception. Technological advancements have led to the development of sophisticated hazard detection and monitoring systems that can quickly identify potential risks in the workplace and technologies to reduce the need to perform more dangerous tasks.

For instance, sensors can identify hazardous gas leaks, temperature variations, and other environmental risks, allowing organizations to mitigate these threats before they endanger worker safety. Digital gas monitors help alert employees to toxic gases, oxygen-deficient zones, and combustible atmospheres, including confined spaces and manholes.

Lone worker monitoring technologies assist in overseeing, safeguarding, and managing employees who work in isolation without direct supervision. Drones can be deployed in hazardous areas, such as confined spaces or work at height, significantly reducing risks for workers.

Technology has also played a significant role in improving the effectiveness of personal protective equipment (PPE)—smart PPE, such as connected hard hats, safety glasses, and gloves—providing real-time data that can help employers address potential safety concerns before they result in accidents or injuries.

Automation and robotics have significantly improved workplace safety by reducing the need for humans to perform dangerous tasks. Robots can be deployed to manage hazardous materials, operate in extreme temperatures, and perform repetitive tasks that could lead to strain or injury in human workers. By automating certain tasks, organizations can reduce the risk of accidents and injuries. Computer vision can be used to identify postures that could lead to workplace injuries with your smartphone camera.

Moreover, innovative training techniques, such as virtual reality simulations, improve employee learning and readiness for potential risks.

From advanced monitoring systems to wearable devices to automation to training, new technology offers innovative ways to protect employees and reduce the risk of accidents and injuries.

Smart Safety Systems Build Capacity for SIF Prevention

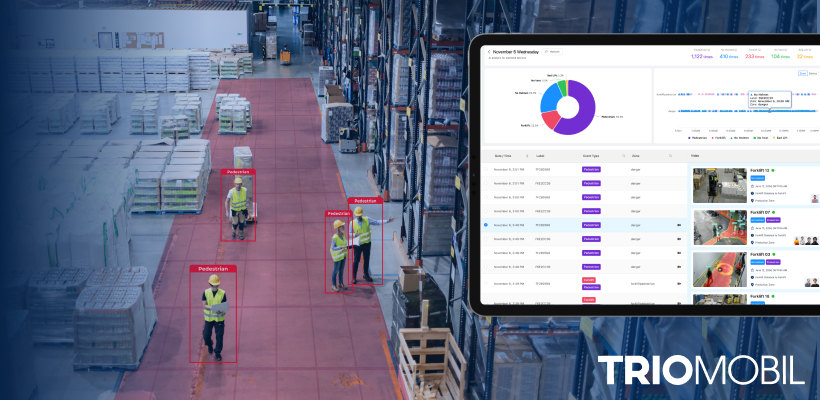

Trio Mobil's Smart Safety Systems exemplify this technological leap. By integrating IoT and AI solutions into industrial environments, the company offers comprehensive solutions that help reduce the risk of incidents and support employee protection:

- UWB-Based Proximity Detection: Ultra-wideband technology creates a real-time safety net by alerting forklift operators to pedestrians in their vicinity. These alerts provide critical seconds to assist operators in reducing the risk of potential collisions, especially in dynamic and crowded environments.

- AI-Powered Tagless Pedestrian Detection: Leveraging advanced AI, Trio Mobil’s systems continuously monitor the entire environment around forklifts and within facilities—without requiring wearable tags. This comprehensive approach enhances safety in dynamic workspaces and minimizes false alarms, making safety measures more effective and unobtrusive.

- Lone Worker Safety Systems: This solution detects inactivity, designed for employees working in isolated or high-risk areas. If an incident occurs, automated alerts provide rapid response, safeguarding both lives and operations.

- Zone-Based Speed Control: Trio Mobil’s technology automatically reduces forklift speeds in designated high-risk zones, minimizing the likelihood of accidents while maintaining workflow efficiency.

- Fleet Management Platform: All-in-One fleet management platform, FleetBridge, integrates cloud technology and IoT to enhance forklift efficiency. It monitors impacts, enables operator access control, and delivers real-time safety insights for optimized operations.

- Data-Driven Unified Cloud Platform for Intelligent Safety & Efficiency: Trio Mobil's AI-powered solutions leverage cloud-based intelligence to enhance workplace safety and operational efficiency.

Enhancing Employee Well-Being with Safety Systems

A workplace equipped with smart safety systems doesn’t just prevent injuries, it promotes employee well-being by creating a safer and more efficient work environment. When employees feel that their organization values safety, their trust in leadership and overall job satisfaction increase. The visible presence of safety measures can also promote mental health and wellbeing, allowing employees to focus on their tasks without worrying about accidents.

Safety systems like those provided by Trio Mobil play a vital role in fostering these positive outcomes. These technologies go beyond accident prevention by embedding safety into the daily operations of the workplace. For example:

- Visible Safety Measures: Employees are more likely to feel secure when they see that systems are in place to address common risks, such as blind spots or high-speed forklift zones. Knowing that advanced technologies are actively monitoring their surroundings builds confidence.

- Proactive Risk Mitigation: Trio Mobil’s smart systems, like real-time alerts and automatic slow down, reduce the likelihood of accidents by addressing risks before they escalate. This proactive approach alleviates stress for employees working in high-risk areas.

- Ease of Use and Reliability: Effective safety systems should be intuitive and reliable, ensuring employees can trust them without needing constant troubleshooting. Technologies that deliver timely alerts without overwhelming workers with false alarms are critical in maintaining operational flow and confidence.

A safer workplace contributes to improved physical and mental health for employees, reducing stress, increasing morale, and encouraging greater engagement with their work.

Real-World Success Stories

Success stories from Trio Mobil’s implementations highlight the tangible benefits of integrating smart safety systems with expert-led strategies. These examples demonstrate how advanced technology, tailored to specific workplace challenges, can create safer, more efficient environments while maintaining operational excellence.

These implementations underscore the scalability and adaptability of Trio Mobil’s solutions. From addressing visibility challenges to enhancing the safety of employees in hazardous zones, these systems offer tailored safety enhancements that meet the unique needs of diverse industries.

Overcoming Barriers to Adopting Safety Technologies

Despite the clear benefits of advanced safety systems, many organizations face resistance when adopting new technologies. Concerns about costs, complexity, and potential disruptions to workflows can slow implementation efforts, even in high-risk environments where these tools are most needed.

The most common barriers include:

- Cost Concerns: Organizations may perceive safety technology as a significant upfront investment without fully considering the long-term savings from reduced accidents, fewer disruptions, and lower insurance premiums.

- Complexity of Integration: Introducing new systems often raises fears about operational downtime, retraining requirements, or compatibility with existing infrastructure.

- Employee Hesitation: Workers might resist unfamiliar systems, especially if they feel the technology adds unnecessary complexity to their workflows or creates an environment of constant monitoring.

To address these barriers, leadership plays a crucial role in guiding the organization through change and the adoption of new technologies. Leaders should set a clear vision for the future and communicate it effectively, which includes demonstrating their commitment to an organizational culture that values safety and explaining how the new technology aligns with the organization’s operational goals.

As new technologies are explored and piloted, organizations should encourage collaboration across various teams and diverse skill sets. Cross-functional teams can work together to tackle complex challenges, creating ownership of the solutions that are adopted.

In addition, organizations should keep employees informed about the organization’s strategies and plans related to technology adoption, providing a clear vision of how the changes will benefit both the company and the workforce. This includes openly discussing the potential impacts on jobs and responsibilities. This could involve providing training that support employees in adapting to evolving roles and responsibilities, ensuring they remain relevant and valuable. Organizations should seek to create an environment where continuous learning is encouraged and celebrated, while acknowledging the potential stress technological changes can bring and by offering resources to support workers’ mental and emotional wellbeing.

Trio Mobil’s solutions are designed to address these challenges directly. By offering modular and scalable systems, safety measures can be gradually integrated into existing operations. This flexibility minimizes disruptions while allowing businesses to tailor solutions to their specific needs. Features like intuitive interfaces and customizable configurations help reduce the learning curve for employees, building trust and confidence in the new technologies.

Transformation of Workplace Safety

Emerging safety technologies can make workplaces of every size and in every industry safer. As we seek a set of tools designed to help organizations better understand, assess and control serious safety hazards and conditions that can lead to SIFs, safety technologies provide such solutions.

Solutions like those offered by Trio Mobil demonstrate that safety systems can be more than just protective measures—they are enablers of a thriving, engaged workforce. By incorporating features such as UWB proximity detection, AI-powered pedestrian safety, and lone worker systems, safety is woven seamlessly into the operational fabric of diverse industries. With Trio Mobil’s AI-driven solutions, workplace safety is evolving into a proactive, intelligent, and integrated approach—one where technology and leadership drive meaningful change. I am excited to work with Trio Mobil on their technological innovations as they help businesses overcome barriers, adopt tailored safety solutions, and foster environments where employees are safe and well.

The message is clear: with more than 5,000 fatalities occurring annually in U.S. workplaces, there is a critical need for more effective preventative measures and systems. There are solutions available now to help American businesses prevent SIFs. Businesses that invest in smart safety systems and embrace a people-first approach will not only meet compliance standards but also achieve greater productivity, resilience, and employee satisfaction.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!