Industrial operations, distribution centers, and warehouses are full of forklifts, trucks, and other material-handling equipment, carrying heavy loads and contributing to the distribution or production of the goods. That is why, in today’s world, forklift fleet management systems have emerged as “must-have” items for more efficient and safer operations.

Forklift tracking systems are beneficial for industrial operations for many different reasons, and other solutions exist for the specific needs of various industries. This comprehensive guide will explore the benefits, technologies, methods, and multiple implementations of forklift tracking systems.

What is Forklift Tracking?

Forklift tracking is monitoring and management of the forklift operations inside a facility. It is a combination of software and hardware that utilizes different technologies. The aim of having a forklift tracking system is not just to know the location of each vehicle in the warehouse but to have an in-depth understanding of the operations, identify bottlenecks, and establish more efficient and safer operations that rely on actual data.

Key Components of Forklift Tracking and Monitoring Systems

Forklift monitoring systems utilize various technologies and hardware to achieve precise tracking and offer real-time data.

Forklift Tracking Hardware

Forklift tracking is an interplay between small electronic devices such as tags and trackers installed on the forklifts & sensors and anchors on the ceiling.

Tags on the forklifts send signals to the anchors attached to warehouse ceilings. This data is then transmitted to the location servers for the exact positioning of the forklift.

GPS (Global Positioning System)

Global Positioning System, GPS, is the fundamental component of forklift tracking systems. GPS trackers installed on the forklifts communicate with satellites to determine their exact position.

The GPS receivers installed on the forklifts use satellite communication to pinpoint their exact position. After that, this data is sent to a centralized server, allowing real-time location monitoring.

While GPS effectively provides actual location data at outdoor locations, alternative technologies such as Ultra-wide Band (UWB) are gaining popularity for more effective location tracking inside warehouses.

Beyond GPS: The Advancement of Ultra-Wideband (UWB) in Forklift Tracking

-in-forklift-tracking.jpg)

GPS system has some limitations regarding providing accurate tracking in indoor locations. UWB technology, on the other hand, offers better precision and real-time tracking even with high-density traffic locations inside warehouses and manufacturing facilities.

Implementing a UWB technology for real-time tracking of forklifts provides opportunities for:

- Accurate forklift positioning: UWB technology allows for safe and effective operation in busy locations by tracking forklifts with 10cm to 1m location accuracy.

- Increased pedestrian and forklift safety: UWB technology can be integrated with RTLS systems to prevent collisions by precisely locating pedestrians and forklifts in real-time.

Read our Complete Guide to Forklift Pedestrian Safety for more information on implementing UWB technology in warehouses to increase forklift and pedestrian safety.

Wireless Communication Technologies

Real-time visibility of each forklift is essential for effectively monitoring and managing warehouse operations. Forklift tracking systems utilize wireless communication technologies such as Wi-Fi to transmit the data collected through tags and anchors.

Telematics and Sensor Integration

Telematics is the application of computer science, telecommunications, and automotive technology to facilitate information sharing between distant objects or systems.

Telematics devices installed on the forklifts gather information on various parameters, contributing to a comprehensive understanding of forklift activities such as operation hours, idle time, engine health, fuel consumption, etc.

As a result, integrating forklift telematics and real-time location tracking systems provides seamless, safer operations that rely on actual data.

If you are interested in learning more about the benefits of telematics devices in forklift fleet management, explore our blog and learn how fleet management can benefit warehouse operations.

Why is Forklift Monitoring Important?

Forklifts and other material-handling equipment are indispensable for today’s warehouse operations and manufacturing centers. However, they carry inherent risks, and they come with their own set of challenges.

Forklift monitoring systems emerge as a solution to addressing these challenges by providing real-time data about forklift activities to avoid accidents, reduce downtime, and streamline operations.

To clarify why forklift tracking systems are essential, we will now explore the benefits of these systems.

Benefits of Forklift Tracking Systems

Imagine a warehouse where all operations run smoothly, safely, and at optimum capacity without encountering problems. Forklift tracking aims to provide this exactly.

In addition to forklift safety, they help unlock many other operational advantages, such as increased efficiency, enhanced maintenance, improved inventory management, and reduced costs. Forklift monitoring systems achieve this by providing real-time data to decision-makers and empowering them to make informed choices.

Safety First: The Role of Forklift Monitoring Systems in Accident Prevention

Safety of the personnel and the material handling equipment should always be the first aim of every industrial operation. Warehouse operators aim to reach maximum safety by implementing solutions, such as forklift collision avoidance systems, traffic management systems inside a facility, or lone worker safety systems.

Establishing an efficient forklift monitoring system complements all these systems to reach a zero-accident workplace. How does a forklift tracking system help to prevent accidents? Let’s explore some of the most efficient ways.

- Speed Monitoring: By setting and enforcing speed limits to prevent fast maneuvering, these systems help to eliminate forklift overturning accidents.

- Impact Detection: By sending immediate alerts upon collisions or incidents, forklift tracking systems enable quick responses and, therefore, prevent any further damage.

- No-go Zone Alerts: Forklift monitoring systems enable defining restricted areas, and the system sends notifications if there is a breach in these zones, alerting authorized personnel to take immediate action.

Efficiency Unleashed: How Forklift Tracking Optimizes Operations

Another key benefit of establishing a forklift tracking system is increased efficiency and optimized operations. Forklift tracking helps identify operation bottlenecks and provides visibility into the effectiveness of the operations. There are several methods for enhancing efficiency with forklift monitoring systems:

- Route optimizations: Forklift monitoring provides historical data to analyze and identify the most efficient forklift routes, minimizing unnecessary travel time.

- Reduced idle time: By effectively tracking periods of inactivity, forklift monitoring systems help to redeploy inactive forklifts, helping to maximize utilization.

- Effective traffic management: Forklift tracking helps to identify congested areas and creates a smoother flow of traffic inside facilities by creating a digital twin of the factory.

Cost Management: Maintenance and Operational Savings with Forklift Monitoring Systems

Increasing efficiency and safety while decreasing costs would be the most significant aim of every plant manager, and forklift monitoring provides this precisely. Tracking forklifts can lead to substantial cost savings by providing:

- Reduced fuel consumption: By optimizing the routes and enabling a more efficient workflow, forklift tracking helps reduce fuel consumption.

- Minimized downtime: Tracking the condition of each forklift and taking necessary actions when an impact occurs prevents unexpected breakdowns, minimizing downtime.

- Reduced insurance costs: Warehouse operations can benefit from reduced insurance costs by showing that they proactively take measures to prevent accidents.

- Better asset utilization: Monitoring forklift fleets helps to improve asset utilization by optimizing their usage.

Forklift Telematics: Redefining Forklift Tracking and Data Analysis

Implementing a forklift tracking system with the necessary technology and hardware is relatively easy. However, to reach optimum operational efficiency and safety, it is vital to establish a system that enables the data gathered from forklift tracking and monitoring to be analyzed. This is where forklift telematics comes into the stage.

Modern telematics systems go beyond just tracking and monitoring the forklifts by collecting, transmitting, and analyzing data about forklift usage, operator behavior, and the condition of the material handling equipment.

Let’s explore how forklift telematics helps analyze data and is an invaluable asset for industrial operations.

Transmission of Data

Forklift telemetry involves transmitting the data collected from forklift monitoring to a centralized system via cellular networks or Wi-Fi. This real-time data transmission helps warehouse operators make instant observations and decisions.

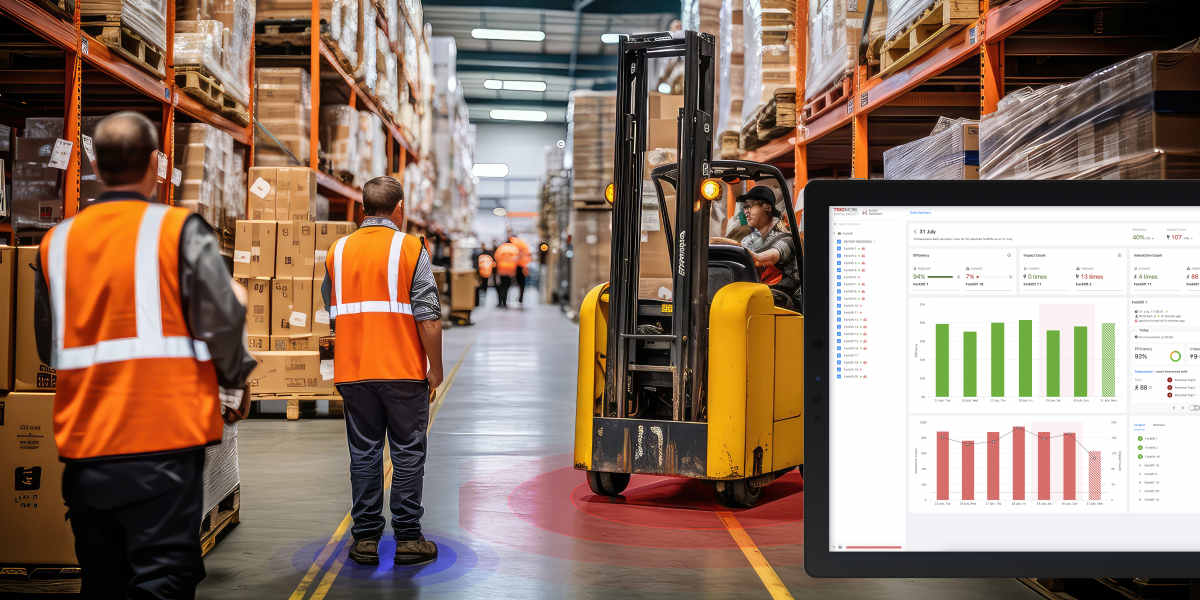

Customizable and User-friendly Dashboards

The data transmitted by the centralized systems are collected on cloud-based software. These real-time data collection sets are then analyzed through this software and become visible to warehouse operators through graphs, charts, tables, and other graphical visualizations. Visualization and categorization of the existing data help plant managers make more informed and strategic decisions.

Forklift telematics software enables customized screens and reports to address the specific needs of various industries. Therefore, it is crucial to own forklift telematics software to analyze the existing data to get the full benefits of forklift tracking and monitoring systems.

Interested in learning more about which type of data is collected through forklift telematics and how they are utilized for warehouse operations? Learn more about our FleetBridge Forklift Fleet Management solution.

Implementing a Forklift Tracking System in Your Business

Every warehouse operation and its safety requirements are unique. Therefore, identifying and then choosing the right forklift tracking system is vital for the efficiency of the operations. There are several factors to consider when choosing the right forklift monitoring system:

- Definition of the priorities and needs: Define the priorities (safety, efficiency, compliance with regulations, etc.) and choose the right system that aligns with them.

- Choosing the right technology: Consider the size and complexity of the operations and determine the accurate technology (GPS, UWB, etc.) that would provide adequate coverage.

- Integration with the existing systems: Verify compatibility with the enterprise resource planning (ERP), safety systems, or warehouse management systems (WMS) that are currently in place.

- Adaptability and scalability for future needs: Consider implementing a system that can change to meet the demands as the operations grow and requirements change.

Trio Mobil's Forklift Tracking System

Trio Mobil offers a comprehensive forklift tracking solution that leverages UWB technology for superior accuracy and real-time insights. Our systems feature;

- High-precision UWB tags and anchors for providing centimeter-level accuracy even in congested areas.

- AI-powered data analytics for generating valuable insights into operator behavior, engine health, and safety risks.

- Customized alerts and reports for receiving real-time notifications about potential hazards and generating detailed reports for analysis.

- Seamless integration with existing systems: Our forklift tracking systems easily integrate with your existing WMS, ERP, or safety systems for a holistic view of your operations.

Forklift tracking systems are now considered necessities rather than luxuries, as they improve efficiency, reduce costs, and increase safety. Implementing a system like Trio Mobil’s would benefit your whole warehouse operations.

For more detailed information on our real-time high-precision forklift tracking solutions, please visit our forklift tracking and monitoring page.

Ready to unlock the power of forklift tracking? Contact us today to discuss your specific needs and explore how our solutions can bring your operations to the next level.