In logistics and warehouse management, forklift telematics has become increasingly central, revolutionizing how businesses manage their forklift operations. As an essential element for greater efficiency, heightened safety, and proactive maintenance strategies, forklift telematics is a testament to technological advancement in industrial environments. This comprehensive technology streamlines operations and aligns with stringent safety standards, such as those set forth by OSHA.

This article explores forklift telematics in-depth, uncovering how it functions, its integral components, its benefits, and its implementation. So, we will highlight the critical importance of forklift telematics in the modern industrial sector, offering insights into how it's reshaping the approach to forklift fleet management and setting new benchmarks in operational excellence.

What is Forklift Telematics?

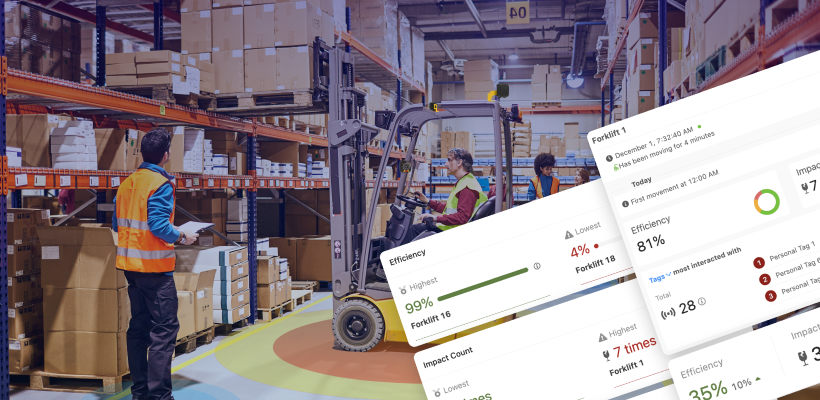

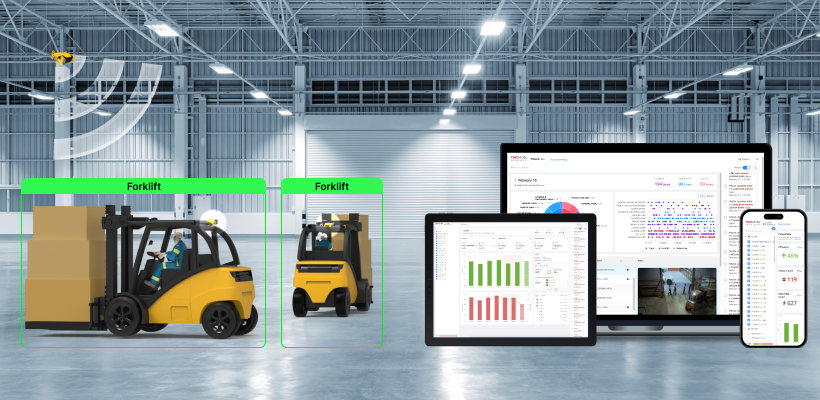

Forklift telematics is a sophisticated integration of telecommunications, informatics, and advanced technological solutions specifically designed to elevate the operational standards of forklift management in industrial settings. This system is engineered to remotely monitor, manage, and enhance the overall performance of forklift operations, encompassing various functionalities.

At its core, forklift telematics involves collecting, transmitting, and analyzing a wealth of data forklifts generate during their operation. This data spans various dimensions, including forklift's location, movement patterns, operational efficiency, maintenance requirements, and overall safety metrics.

How does Forklift Telematics work?

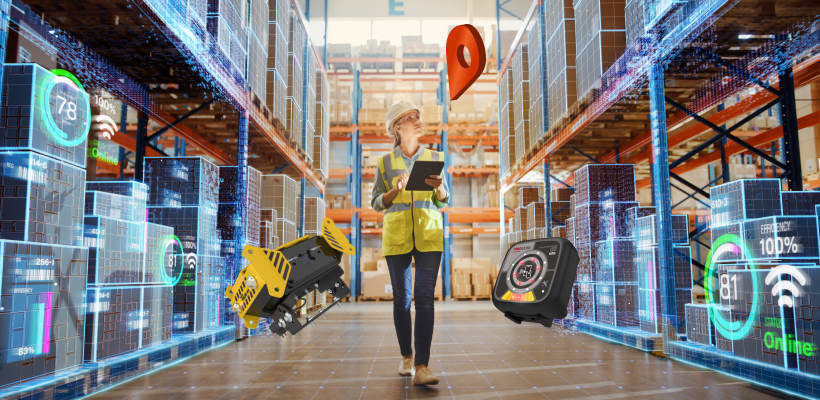

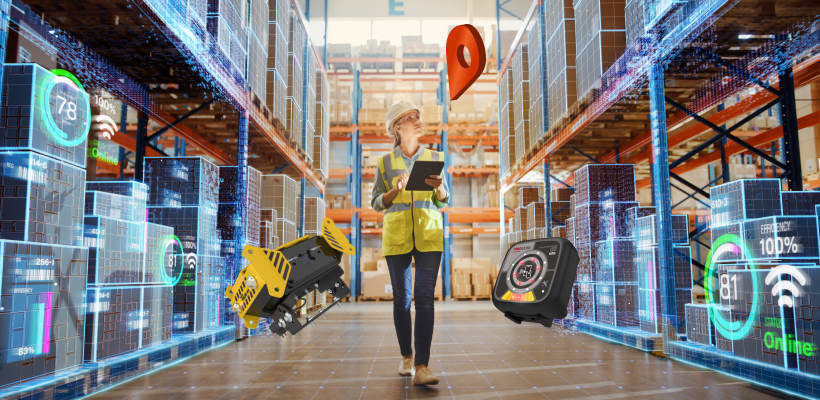

The operation of forklift telematics is a fascinating intersection of advanced technologies, including sensor deployment, GPS tracking, and sophisticated data processing capabilities. This combination of technologies converges to create a comprehensive and real-time monitoring system for forklift operations.

Here's a closer look at the individual components and their roles in the functioning of forklift telematics:

Sensor Deployment

The sensors installed on forklifts are the core of forklift telematics. They are designed to capture a wide range of data, such as impact, location, and vibration.

Some sensors are specialized to detect mechanical wear and tear, such as notifying managers when an impact occurs. They constantly gather data while the forklift operates, providing a continuous stream of up-to-date information.

GPS Tracking

GPS tracking is integral to forklift telematics, offering precise geolocation capabilities. When combined with RTLS sensors, this technology allows real-time tracking of each forklift's position within a facility. It’s particularly valuable in large or complex environments where keeping track of multiple vehicles can be challenging. The GPS data is used for location tracking, enhancing operational efficiency, and reducing unnecessary travel or idle time. This data can also be analyzed to optimize routes.

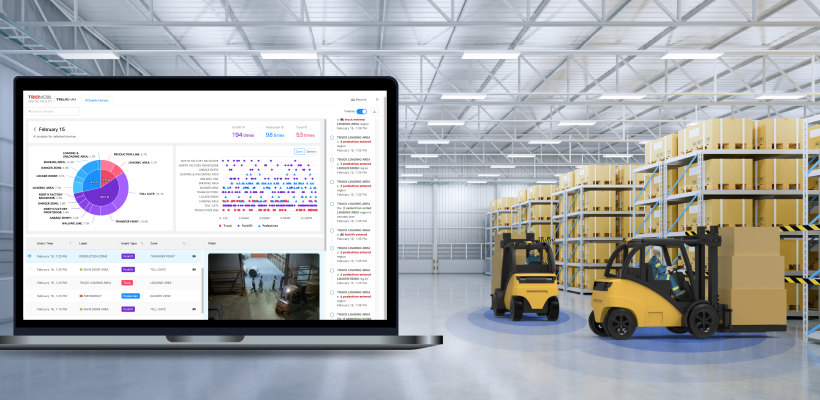

Data Transmission to Cloud-Based Systems

The data collected by the sensors and GPS unit is transmitted to cloud-based systems, typically via wireless networks. This transmission is crucial as it enables the real-time updating and accessibility of data. Once in the cloud, this data is stored securely and is readily accessible for analysis. Cloud technology offers scalability and reliability, allowing for the simultaneous management of vast amounts of data from multiple forklifts.

Advanced Data Processing and Analytics

Once the data reaches the cloud, it undergoes advanced processing and analytics. Sophisticated algorithms analyze this data to extract meaningful insights and patterns. This processing can reveal operational inefficiencies and potential safety hazards. By analyzing trends over time, the system can identify areas for operational improvement and suggest measures to enhance safety.

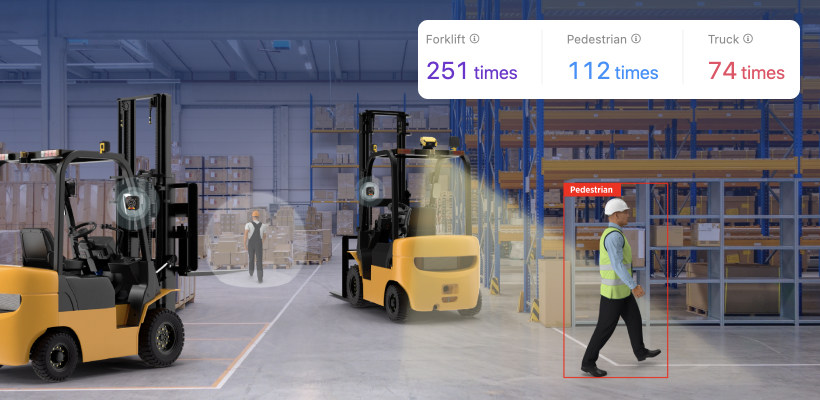

Real-Time Monitoring and Reporting

The culmination of this process is the ability to monitor forklift operations in real-time and generate comprehensive reports. Fleet managers and operators receive instant feedback and alerts on various aspects of forklift usage. This real-time monitoring capability is crucial for immediate response to potential issues and making informed decisions based on current data.

Features of Forklift Telematics

Forklift telematics systems offer a range of features designed to enhance the management and operation of forklift fleets. These features improve the day-to-day running of warehouse and logistics operations and contribute to long-term equipment health and operational efficiency.

Asset Tracking

Asset tracking is a fundamental feature of forklift telematics, enabling real-time location tracking of forklifts. This feature is vital in large warehouses and job sites, as it allows fleet managers to know the location of each forklift at any given time.

Asset tracking helps optimize vehicle deployment and provides a more efficient use for forklifts.

Boosting Efficiency & Uptime

Forklift telematics systems are designed to enhance overall operational efficiency and maximize uptime. By providing data on forklift usage patterns, these systems help identify operational bottlenecks and inefficiencies.

They enable managers to make data-driven decisions about forklift deployment and scheduling maintenance, reducing downtime and increasing productivity. The insights gained from telematics data can also be used to train operators to handle forklifts more efficiently.

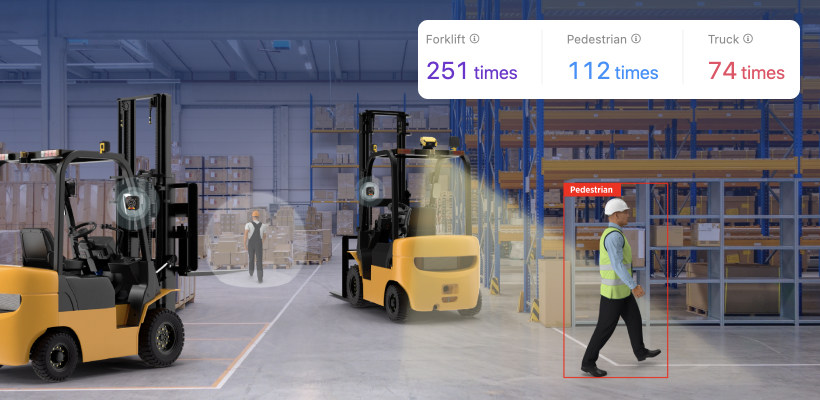

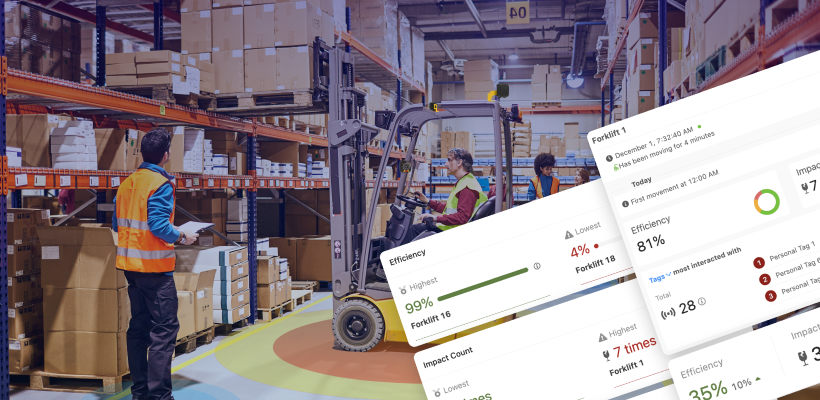

Impact Detection & Management

One of the most significant benefits of forklift telematics is the ability to provide alarms and notifications when an impact occurs. By constantly monitoring impact data, telematics functions as a forklift impact monitoring system that can help identify potential issues before they turn into costly repairs.

This feature allows maintenance teams to address minor issues promptly, avoiding major breakdowns and helping that the forklifts are always in optimal working condition. As a result, this proactive approach extends the life of the forklifts and enhances the safety of operators and other personnel.

Enhanced Safety with Operator Access Control

Another important benefit of telematics is they provide access control systems, preventing unauthorized use of forklifts. When an NFC-based system is installed, only authorized personnel are able to operate forklifts at the maximum speed.

By monitoring authorized operator activity, organizations can provide compliance with safety protocols and regulatory standards, mitigating the risk of unauthorized or untrained personnel operating forklifts. This granular tracking not only enhances safety but also facilitates optimized resource management, enabling data-driven forklift allocation to maximize efficiency and productivity.

Extra Layer of Safety with Pre-Operational Safety Checklist

Implementing a pre-operation forklift safety checklist feature in forklift telematics offers a robust mechanism for maintaining safety and providing compliance in industrial environments.

Organizations establish a proactive safety protocol by mandating forklift operators to pass safety questions before gaining full-speed access. In the event of failure, the system activates low-speed mode, accompanied by online record-keeping and alarms to prompt immediate attention.

Additionally, incorporating cloud-driven safety quizzes further verifies operator competency, with real-time reporting capabilities providing continuous monitoring of safety compliance and performance. Through this comprehensive approach to safety checklist facilitation and online compliance tracking, managers can cultivate a culture of safety, driving ongoing improvement and operational excellence.

What benefits does Forklift Telematics offer?

Forklift telematics systems offer pivotal advantages, enhancing safety and operational efficiency in material handling and logistics.

Benefits of Forklift Safety

Forklift telematics significantly elevates workplace safety standards through continuous monitoring and proactive management of forklift operations.

Key safety benefits include:

- Real-time Monitoring: Constantly tracks forklift movements and operations to identify and address safety risks immediately.

- Collision Avoidance: Integrates features like proximity alerts to help reduce the risk of incidents in high-traffic areas.

- Enhanced Operator Accountability: Encourages responsible driving by recording impacts.

- Compliance with Safety Protocols: Helps promote adherence to safety standards and regulations, reducing the likelihood of accidents and injuries.

Benefits of Operational Efficiency

Forklift telematics systems optimize the efficiency of forklift operations, leading to streamlined workflows and improved productivity. The efficiency benefits include:

- Route Optimization: Provides data that can be used to specify the most efficient routes, reducing travel time and increasing throughput.

- Reduced Idle Times: Monitors forklift usage to identify and decrease periods of inactivity.

- Proactive Maintenance: Records and sends alarms when an impact occurs, preventing further breakdowns and prolonging equipment life.

- Workflow Bottleneck Identification: Uses telematics data to pinpoint and address inefficiencies in operational processes.

- Data-Driven Decision Making: Empowers managers with actionable insights for strategic planning and resource allocation.

How to Install Forklift Telematics for Your Operations?

Installing a forklift telematics system in your operations involves a series of strategic steps to provide seamless integration and optimal functionality.

Here's a general guideline:

- Assess Your Needs: Evaluate your fleet's specific requirements, including the size of your operations, the number of forklifts, and the type of data you wish to track.

- Choose the Right System: Consider features, scalability, and ease of use to Select a forklift telematics system that best fits your operational needs.

- Plan the Installation: Schedule the installation to minimize disruption to your operations. This might involve a phased rollout or installation during off-peak hours.

- Professional Installation: For optimal performance and reliability, provide trained professionals to install sensors and telematics hardware on your forklifts.

Trio Mobil's successful team will help you assess your safety needs with field visits and install the equipment easily thanks to their plug&play structure. In addition, our dedicated team will provide the necessary training and support after installation. Discover how Trio Mobil's expert team can enhance your safety measures.

Forklift Fleet Management via Forklift Telematics

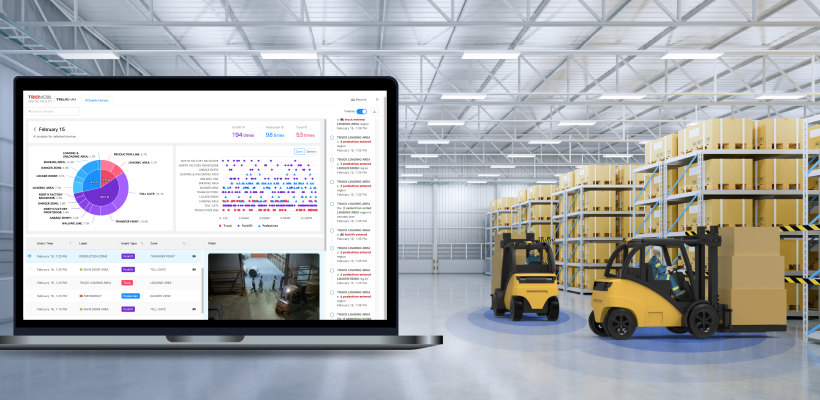

The adoption of forklift telematics in fleet management has revolutionized the monitoring and management of these critical assets. This technology provides real-time insights into various aspects of forklift performance, such as location, speed, and idle time. Such comprehensive monitoring is pivotal for fleet managers, enabling them to optimize the use and deployment of forklifts across different operations. This real-time data is crucial in making informed decisions that improve operational efficiency.

Forklift telematics excels in identifying and rectifying inefficiencies in forklift usage. Analyzing data like idle times, route patterns, and load handling pinpoints areas needing improvement, leading to more efficient operations. This insight proves invaluable in boosting productivity, as it facilitates the adjustment of workflows and schedules based on concrete usage data, thus cutting operational costs.

Forklift telematics introduces a proactive approach to maintenance and safety. Moving away from traditional estimates-based maintenance schedules, it utilizes real-time data to alert for preventing expensive breakdowns and extending fleet lifespan. Additionally, it enhances safety and compliance by monitoring adherence to operational safety standards and guidelines. This includes tracking speed limits and operator access control, significantly reducing workplace accidents, and promoting a safer working environment.

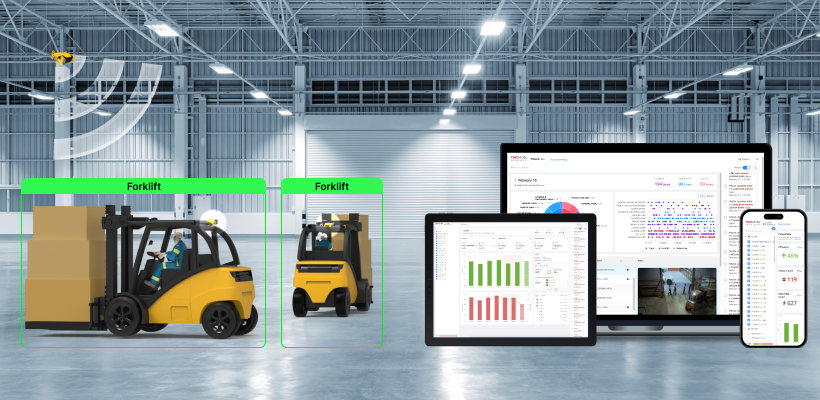

Trio Mobil’s Forklift Telematics Solution

Trio Mobil offers a comprehensive and advanced solution for forklift fleet management: FleetBridge. This system harnesses the power of real-time visibility and data-driven insights to enhance the performance and safety of forklift operations significantly.

FleetBridge operates by seamlessly integrating cutting-edge hardware devices into your forklift fleet. These devices serve as anti-collision systems and cloud gateways, eliminating the need for extra hardware and providing cost-effectiveness. The hardware continuously collects valuable data related to forklift operations, efficiency, and event data. This data is then securely transmitted in real-time through the cloud gateway to a cloud-based platform, allowing immediate access to crucial information about your forklift fleet.