Managing the costs and the productivity of the warehouses and logistics operations is a continuous struggle. Effective forklift fleet management becomes crucial in maintaining a competitive edge in industries where time and precision are critical, such as manufacturing, logistics, and distribution.

Forklift fleet management is crucial for optimizing the efficient use and utilization of forklifts and trucks. In this article, we will look into forklift fleet management systems to understand what they are and how they can benefit warehouse operations and production sites.

What is a Forklift Fleet Management System?

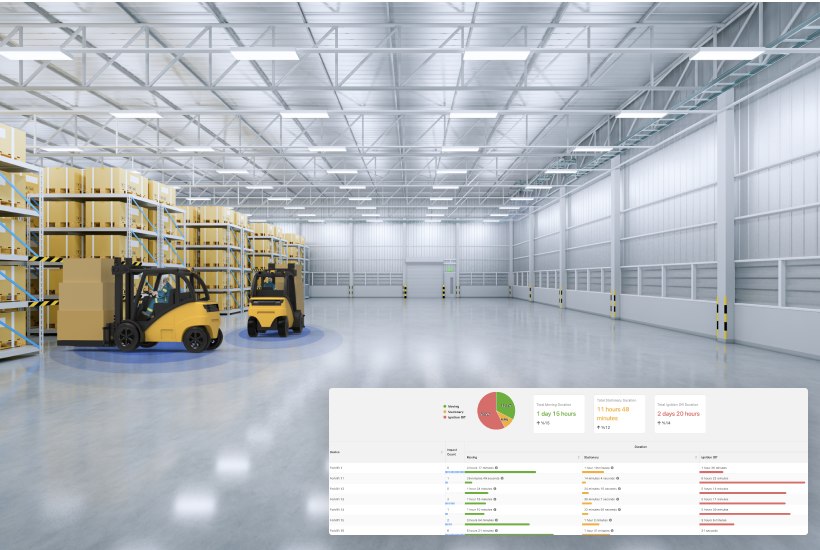

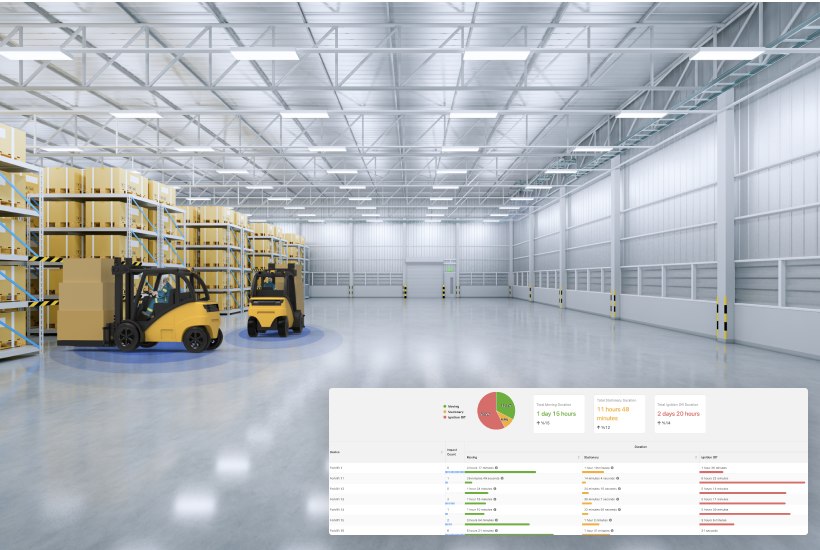

A forklift management system combines hardware and software components to oversee a fleet of forklifts or other material-handling equipment.

Forklift fleet management systems track and monitor the location and usage of each forklift in real-time, facilitating better coordination and utilization of the fleet. It is instrumental for forklift safety in scheduling regular maintenance checks and alerting for necessary repairs, thereby preventing breakdowns and extending the lifespan of the vehicles.

With the integration of the latest technologies of IoT & AI, these systems offer valuable data to conduct analysis, which can help reduce costs, improve overall efficiency, and enhance productivity.

What are the Forklift Fleet Management Solutions?

Forklift Fleet Management Solutions encompass a range of tools and technologies designed to optimize the operation, safety, and maintenance of forklift fleets in industrial and warehousing environments.

These solutions typically include:

Forklift Fleet Tracking

One of the critical components of fleet management is forklift fleet tracking, which provides real-time visibility of the location and status of the forklifts.

With real-time tracking of each forklift, it is possible to optimize routes and identify potential issues that impact operations beforehand. It is also vital to provide better coordination between operators.

Forklift Fleet Management Software

Forklift fleet management software plays a vital role in streamlining operations. It is a centralized data management platform that enables businesses to schedule maintenance, track fuel consumption, generate analytics reports for data-based decision-making, and monitor forklift performance.

To understand the ins and outs of any fleet, forklift fleet management software offers valuable functions and metrics as follows:

Real-Time Monitoring and Tracking

Real-time tracking and monitoring of each forklift in the fleet is one of the main functions of forklift fleet management software. With GPS trackers and forklift telematics hardware, fleet managers can monitor any forklift's real-time and concise location or status.

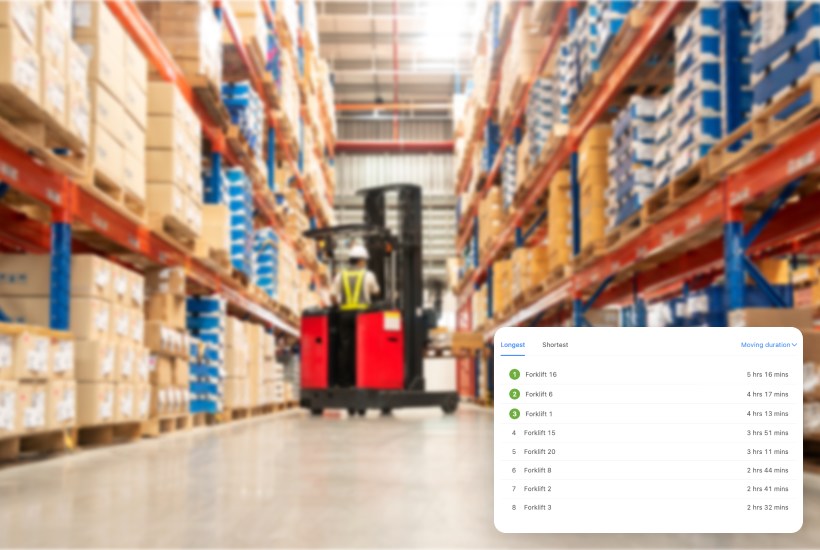

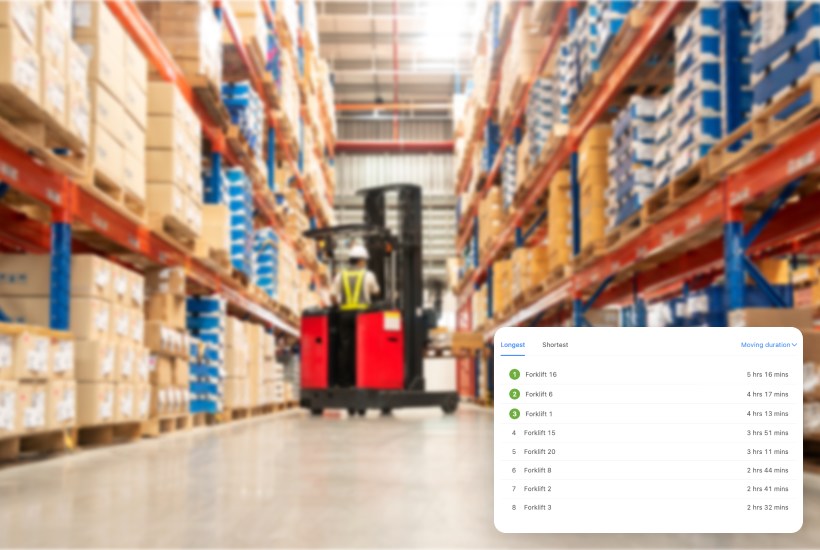

Usage Analytics

Fleet management software collects data such as idle time, running time, operation hours, or any other task. Fleet managers can use this data to identify patterns and trends for better fleet optimization.

Maintenance Management

Regular maintenance checks must be conducted for the operators' and the forklifts' safety.

Forklift fleet management software monitors the health of the forklift and triggers alarms when maintenance is due. By proactively preventing unexpected breakdowns, this approach helps to reduce downtime.

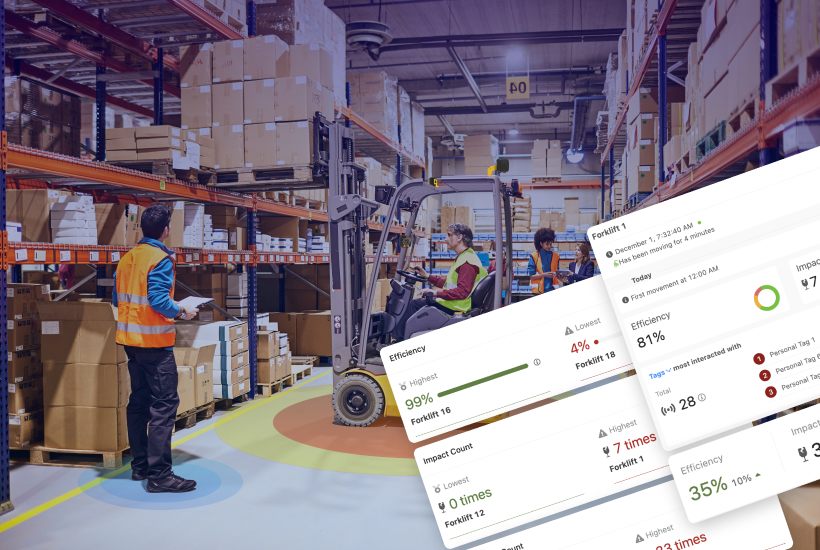

Impact Management

Forklift fleet management systems are integrated with sensors that can track impact records and generate alarms when an incident occurs, making it possible for fleet managers to take necessary measures for forklifts' health.

Compliance and Safety Features

Forklift safety regulations are complicated but critical steps to complete for safer and more efficient operations. Fleet management software includes features that monitor and enhance safety protocols, encouraging forklift operators to adhere to safety requirements, such as pre-operation safety checklists.

User-Friendly Interface

Fleet managers and forklift operators should be able to reach any crucial information they require quickly and intuitively because of the nature of the operations at the warehouses. Fleet management software should have a user-friendly interface that makes navigating through screens easy, accessing valuable information quickly, and generating customized reports with a click.

How does the Forklift Fleet Management System work?

Forklift fleet management systems combine hardware and software solutions with different key components. These components can differ for each fleet management system.

However, their duty is similar: To provide a better and more efficient running of operations.

Workflow of Forklift Fleet Management System

An efficient fleet management system requires essential steps to work. These steps include installing the hardware on the forklifts, collecting and transmitting the data, and processing and analyzing the data.

Let's have a deeper look at how these systems work.

Hardware Installation

The first step to implementing an efficient forklift fleet management system is to install hardware components on each forklift. These can be telematics devices, GPS trackers, sensors, or onboard computers.

Data Collection

The hardware on the forklifts continuously collects data as the forklifts operate. GPS trackers on the forklifts provide real-time location information, as the sensors monitor engine performance, fuel consumption, and vibration levels. Telematics devices, on the other hand, transmit this data to a centralized server.

Data Transmission

Data collected by telematics devices is transmitted to a cloud-based platform or a centralized server in real time; fleet managers can access the latest data about their fleet.

Data Processing

This data is processed by advanced algorithms and then can be observed through analytics dashboards to interpret the information and generate insights that can be acted upon.

It is important to identify patterns, predict maintenance needs, and analyze existing statistics to make full use of the fleet management systems.

Benefits of Forklift Fleet Management

There are several benefits of implementing a comprehensive forklift fleet management system, including:

- Reduced Costs: Fuel tracking and management, maintenance scheduling, and efficient route planning contribute to cost savings.

- Enhanced Safety: Real-time tracking of the forklifts offers a safer working environment by making it possible to pinpoint possible accident areas, such as crowded sections, and take necessary precautions to prevent them.

- Increased Productivity: Streamlining operations and optimizing fleet utilization help improve operational productivity.

- Data-driven Decision Making: Forklift fleet management systems offer real-time and historical data to make strategic decisions for continuous improvement.

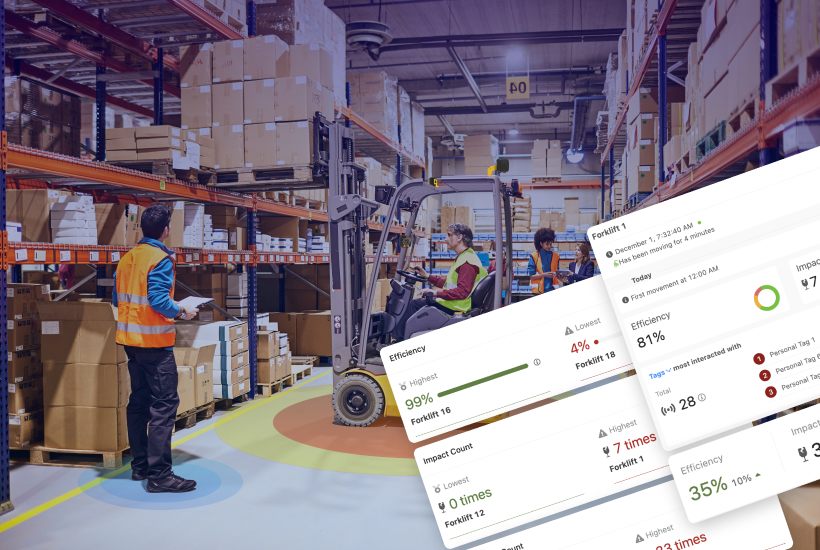

Trio Mobil's Forklift Fleet Management Solution: FleetBridge

Choosing the right forklift fleet management system for your company is very important because it has to be compatible with the brand of your forklift fleet and adaptable to your company's requirements.

As Trio Mobil, workplace safety and industrial efficiency are our top priorities. We offer comprehensive solutions for our customers, and FleetBridge is our add-on solution to increase productivity further and enhance safety in industrial settings.

FleetBridge is a system that seamlessly integrates into the forklift fleet, providing advanced features such as real-time tracking, impact detection and management, operator access control, real-time alarms, and a pre-operation checklist.

For more detailed information about our cutting-edge, modular, plug-and-play solutions, browse our website or request a demo to see how our forklift safety system works.