How to Evaluate the Best Forklift Safety System Providers: Decision-Maker Guide

The question of who is the “best forklift safety system provider” comes up frequently as organizations look to improve workplace safety and meet growing regulatory and operational expectations. As industrial operations become denser, faster, and more complex, safety leaders are under pressure to understand not just what a system detects, but how it helps teams recognize, prioritize, and manage risk over time.

Many forklift safety solutions promise alerts or visibility. Far fewer help organizations understand where risk concentrates, which scenarios carry the highest potential impact, and how safety insights translate into informed action across sites.

This guide explains how decision-makers should evaluate forklift safety system providers today. Instead of comparing vendors, it focuses on the structural criteria that define effective, scalable, and responsible safety systems in real operating environments.

What Defines the Best Forklift Safety System Provider?

The best forklift safety system providers support layered safety, risk prioritization, privacy-by-design data handling, and scalable architecture rather than relying on single-sensor detection or isolated alerts. All in all, there are five criteria decision-makers should use to evaluate forklift safety systems:

- Risk visibility beyond alerts

- Serious Injury or Fatality (SIF) level prioritization

- Layered detection architecture

- Action-driven analytics that support follow-up decisions

- Ethical and privacy-aligned data handling

The sections below explore each of these criteria in more detail.

From Alerts to Risk Visibility

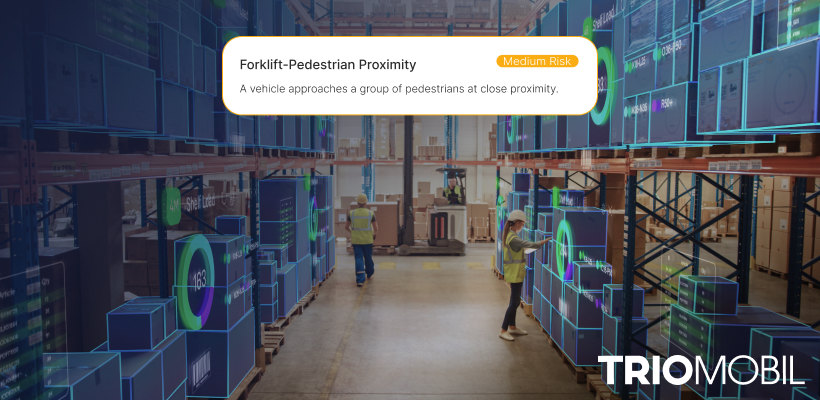

One of the first criteria decision-makers should examine is whether a forklift safety system focuses only on alerts or provides broader risk visibility. Many systems are designed to trigger warnings when a specific condition is detected, such as an object appearing near a forklift. While alerts can be helpful, they represent only a small part of an effective safety approach.

In complex industrial environments, risks are rarely isolated events. Forklift and pedestrian interactions, unsafe behaviors, or congestion in specific zones often occur repeatedly and follow patterns over time. Systems that focus solely on individual alerts may notify operators in the moment, but they provide limited insight into why these situations keep happening or where attention should be prioritized.

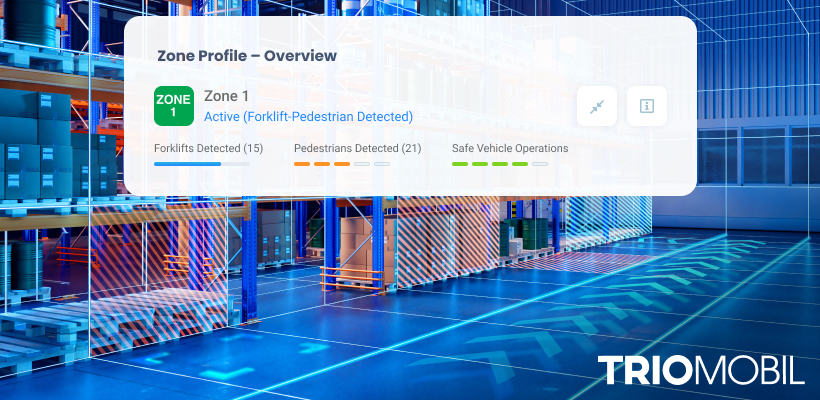

Risk visibility goes beyond momentary notifications. It refers to the ability to understand how often certain risks occur, in which areas, under what conditions, and during which shifts or activities. This level of visibility helps safety teams move from reactive responses to more informed decision-making.

When evaluating providers, decision-makers should look for solutions that support this broader perspective by:

- Capturing risk-related events consistently across operations

- Providing context around where and when risks occur

- Helping identify recurring patterns rather than isolated incidents

- Supporting supervisors and safety teams with insights that guide follow-up actions

Ability to Prioritize High-Risk and SIF-Critical Events

Not all safety risks carry the same potential impact. One of the most important criteria when evaluating a forklift safety system provider is how effectively their solution helps teams prioritize risks that could lead to serious injury or fatality (SIF). Systems that treat every alert the same can overwhelm operators and supervisors, making it harder to focus on the situations that matter most.

Decision-makers should look for providers that support structured risk prioritization, including:

- Clear differentiation between risk levels: The ability to classify events as High, Medium, or Low risk based on context, proximity, and behavior, rather than triggering identical alerts for every detection.

- Focus on SIF-related scenarios: Support for identifying activities with higher SIF potential, such as forklift and pedestrian proximity, distracted vehicle operation, unsafe work at height, or entry into restricted zones.

- Context-aware risk assessment: Evaluation of where the risk occurs, how frequently it repeats, and under what operating conditions, rather than relying on isolated events.

- Reduced alert fatigue for operators: Prioritization helps limit unnecessary notifications and supports trained operators by drawing attention only when risk levels justify intervention.

- Actionable insight for safety teams: Severity-based classification enables EHS and operations teams to allocate time and resources more effectively, focusing investigations and corrective actions on higher-impact risks.

Layered Collision Avoidance Instead of Single-Technology Dependence

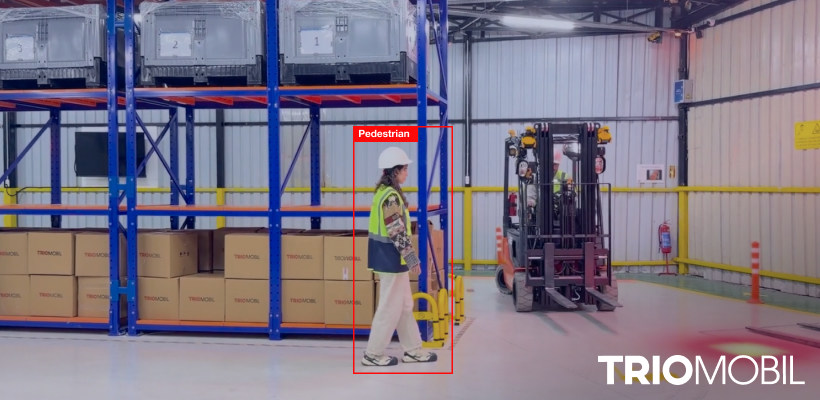

Another key criterion when evaluating a forklift collision avoidance and pedestrian safety solution is whether the system relies on a single detection technology or supports a layered safety architecture.

Single-layer systems typically reduce forklift–pedestrian collision risk by ~45%.

However, industrial environments are inherently complex, and no single pedestrian detection method performs reliably under all operating conditions.

By contrast, multi-layered configurations expand protection coverage up to ~90–95% by combining complementary detection methods and increasing overall situational awareness. Decision-makers should assess providers based on the following considerations:

Recognition of real-world operating challenges:

Industrial sites include blind corners, racking systems, mixed traffic, backlighting, dust, and constantly changing layouts — all of which directly impact pedestrian detection performance and collision risk.

Avoidance of single-technology dependence:

Solutions based on only one sensing method (such as camera-only pedestrian detection) may face limitations in occluded, low-visibility, or high-traffic environments.

Support for layered collision avoidance configurations:

A layered approach combines complementary technologies — such as AI cameras with pedestrian detection technologies and tag-based proximity systems — to expand detection coverage and improve awareness across a wider range of scenarios.

Improved performance in challenging conditions:

Layered safety maintains reliable awareness even in occluded and back-lit environments, helping detect pedestrians behind obstacles, around corners, or in uneven lighting.

Operator-assist safety philosophy:

Layered collision avoidance systems are designed to support trained operators with timely visual and audible alerts, enhancing pedestrian safety rather than acting as fully autonomous or fail-safe control systems.

Site-specific flexibility:

Effective providers recommend collision avoidance configurations based on facility layout, traffic density, and operational risk profile — not a one-size-fits-all solution.

Transparent communication of system performance:

Reliable providers clearly explain how pedestrian detection and collision avoidance performance depends on site conditions, configuration, and maintenance, and how a layered safety approach helps manage these variables.

Data That Leads to Action, Not Just Dashboards

Many forklift safety systems generate large volumes of data, but not all of that information leads to meaningful improvement. When evaluating a provider, decision-makers should look beyond dashboards and metrics and focus on how effectively data supports real-world action.

Key criteria to consider include:

- Clarity over volume: Safety data should highlight what matters most, rather than overwhelming teams with raw event counts or complex charts.

- Actionable insights, not passive reporting: The system should help safety teams understand which risks require follow-up, investigation, or corrective measures.

- Identification of recurring patterns: Repeated behaviors, locations, or time-based trends often indicate deeper operational issues that need attention.

- Support for root-cause analysis: Data should provide enough context to help teams understand why a risk occurred, not just that it happened.

- Alignment with daily safety workflows: Insights should be easy to review, share, and incorporate into toolbox talks, safety meetings, and continuous improvement processes.

- Balanced support for operators and supervisors: Information should assist trained operators with awareness while giving supervisors and EHS teams a broader view of risk across shifts and zones.

- Measured performance over time: Providers should emphasize improvement trends across defined scenarios and operating conditions, rather than one-time results.

Privacy, Ethics, and Regulatory Readiness

AI-powered forklift safety systems operate in environments where people work every day. For this reason, privacy and ethical use are not secondary considerations. They are a core evaluation criterion when choosing a provider.

Decision-makers should assess whether a provider clearly explains how video and data are handled and whether the system is designed to support safety objectives without creating intrusive monitoring practices. Trust from employees and works councils often depends on this transparency.

What to look for in a responsible approach

Privacy-by-design features

A strong solution supports privacy from the outset, not as an afterthought. This may include options such as automatic blurring of faces or bodies and limits on who can access recorded footage.

Purpose-limited use of data

Safety systems should focus on identifying risk conditions and supporting safer operations. Data should not be positioned as a tool for measuring individual performance or enforcing disciplinary action.

Regulatory alignment

Providers should demonstrate readiness for GDPR and similar regulations by supporting controlled data access, configurable retention periods, and secure handling of video and event records.

Ethical AI principles

Decision-makers should expect clear communication around how AI models are used, under which conditions they perform reliably, and where limitations may exist. Ethical systems are transparent about operating conditions and avoid claims of autonomous or guaranteed outcomes.

Scalability Across Sites, Fleets, and Use Cases

What works in a single warehouse does not always translate easily across multiple sites or mixed fleets. A key criterion for identifying the best forklift safety system provider is the ability to scale safely and consistently as operations evolve.

Decision-makers should look beyond initial deployment and evaluate how well a solution adapts to growth, operational change, and different risk environments.

Key scalability considerations

| Evaluation Area | What to Look For | Why It Matters |

|---|---|---|

| Fleet diversity | Compatibility with different forklift brands, models, and energy types | Mixed fleets are common and should not require separate safety systems |

| Multi-site rollout | Ability to deploy consistently across multiple facilities | Supports standardized safety practices and reporting |

| Configurable risk zones | Site-specific rules for speed, proximity, or alerts | Each facility has unique layouts and traffic patterns |

| Modular architecture | Features that can be added or adjusted over time | Allows safety systems to grow without full replacement |

| Centralized visibility | Aggregated insights across sites and regions | Helps leadership compare trends and identify best practices |

| Local adaptability | Configuration based on environment and workflows | Avoids one-size-fits-all implementations |

| Operational continuity | Minimal disruption during expansion or updates | Safety improvements should not slow down operations |

Support, Partnership, and Long-Term Fit

Choosing a forklift safety system provider is not only a technology decision. Long-term success depends on the quality of partnership, ongoing support, and how well the provider aligns with operational realities over time.

Decision-makers should evaluate providers based on the following criteria:

- Structured onboarding and commissioning: Support during initial setup, configuration, and calibration helps align the system with site conditions and risk profiles from the start.

- Operator and supervisor training: Training should focus on proper system use, understanding alerts, and reinforcing safe working practices rather than creating reliance on technology alone.

- Clear operator-assist positioning: Providers should consistently communicate that systems support trained operators and do not replace safe behaviors or procedures.

- Ongoing technical support: Access to diagnostics, updates, and responsive assistance is important for maintaining reliable performance over time.

- Configuration and maintenance guidance: Providers should explain customer responsibilities such as camera positioning, lens cleanliness, and routine checks that influence system effectiveness.

- Adaptability to operational change: As layouts, traffic patterns, or workflows change, the provider should support reconfiguration without requiring major system overhauls.

- Transparency around performance conditions: Trustworthy providers communicate how performance depends on environment, configuration, and maintenance, rather than presenting static performance claims.

- Long-term roadmap and continuity: A clear development roadmap helps organizations understand how the solution can evolve alongside their safety strategy.

How Forklift Safety Systems Fit Into Modern Industrial Safety Programs

Forklift safety technologies are increasingly evaluated as part of broader industrial safety management systems rather than standalone tools. Within this context, safety leaders are aligning forklift risk management with EHS digital transformation initiatives that focus on visibility, prioritization, and continuous improvement.

Modern solutions function as operator-assist technology, supporting trained personnel with awareness and context rather than autonomous intervention. As organizations mature their approach, AI-powered industrial risk monitoring is used to identify recurring exposure patterns, support preventive planning, and inform site level safety strategies across operations.

Choosing Best Forklift Safety System Provider Based on Criteria, Not Claims

The search for the best forklift safety system provider often starts with bold promises and feature comparisons. However, meaningful and lasting safety improvements come from a deeper evaluation of approach rather than marketing claims. Decision-makers benefit most when they focus on how a provider supports risk visibility, prioritizes high-risk scenarios, and fits into real operational conditions.

An effective forklift safety system should assist trained operators, support layered safety configurations, and provide insights that help organizations understand and manage risk over time. Equally important are transparency around performance conditions, respect for privacy, and the ability to scale across sites and evolving workflows. These criteria help organizations move beyond reactive safety measures and toward more consistent, informed decision-making.

As a provider working closely with industrial safety teams worldwide, Trio Mobil applies these principles through operator-assist solutions designed to support safer operations under defined conditions. By evaluating providers through clear, practical criteria, organizations can make more confident choices that align with their safety goals, regulatory responsibilities, and long-term operational needs.

How Trio Mobil Applies These Criteria in Practice

After reviewing the evaluation criteria above, decision makers often seek clarity on how these principles are applied in real operational environments. Trio Mobil follows a structured, site driven process designed to align safety technologies with actual operating conditions and defined risk scenarios.

1. Site Based Safety Analysis

Each engagement begins with a structured assessment of the working environment to better understand site specific risk factors.

Key focus areas include

- Identification of blind spots and areas with limited visibility

- Mapping of high traffic zones and shared forklift pedestrian routes

- Review of recurring interaction points and observed patterns over time

- Consideration of layout constraints, workflows, and operational conditions

This step supports informed decision-making by grounding recommendations in observed conditions rather than assumptions or generalized benchmarks.

2. Tailored Safety Solution Design

Insights from the site analysis are used to configure safety solutions based on the identified environment and risk profile.

This design phase may include

- Selection of layered safety technologies appropriate to site conditions

- Configuration of proximity, zone, and behavior-related scenarios

- Alignment of alerts with operator assist principles and defined thresholds

- Adaptation to factors such as lighting, traffic density, and layout complexity

Solutions are designed to support trained operators and existing safety practices, with configurations adapted to operational realities rather than fixed or universal setups.

3. Safety Driven Proposal and Deployment Planning

Assessment findings are translated into a structured proposal that outlines how solutions may be deployed and monitored over time.

Each proposal typically includes

- Recommended solution configurations and system architecture

- A phased deployment and commissioning approach

- Defined safety indicators linked to observed risk scenarios

- Considerations for operational continuity and workforce protection

This process is intended to help organizations strengthen safety practices in a transparent and measurable manner, supporting ongoing risk management and compliance objectives.

By applying the same evaluation criteria used when assessing forklift safety system providers to its own delivery approach, Trio Mobil aims to align technology, process, and operational conditions throughout each stage of deployment.

Whether in a single warehouse or across dozens of sites, Trio Mobil’s modular systems scale easily, helping organizations achieve safer and more productive operations worldwide.

If your organization is evaluating forklift safety technologies or defining layered safety standards, our team can support site-specific assessments aligned with your operational conditions.

How Safety Leaders Apply These Principles

Organizations across food & beverage, automotive, retail, and heavy industry have adopted layered forklift safety strategies following these criteria.

Teams such as Ford, Beko, Unilever and Collins Aerospace have publicly shared how structured risk visibility, multi-layered detection, and ethical deployment frameworks now support their daily safety operations. Their success stories highlight one consistent theme: Sustainable safety improvement happens when technology fits operational reality.

Disclaimer:

Trio Mobil solutions are operator-assist aids. They do not replace safe working practices or prevent all incidents. Performance depends on operating conditions and configuration; see product documentation.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!