What OSHA’s 2024 Injury Data Reveals About Risk by Industry

OSHA’s 2024 Injury Tracking Application data shows that injury and illness figures remain largely flat compared to 2023. At first glance, this may suggest stability. In reality, it points to something else entirely.

Flat numbers do not indicate lower risk. They indicate that the same exposure patterns continue to exist across industrial environments.

Material handling, overexertion, falls, and vehicle-related incidents remain among the most common causes of recorded injuries. These are not new challenges. They are recurring ones. Understanding where injuries concentrate helps organizations focus on preventive actions that address risk before incidents occur.

This article explores how OSHA’s 2024 injury data highlights persistent, sector-specific risk patterns and why earlier visibility, layered safety approaches, and data-driven awareness play a critical role in supporting more proactive industrial safety strategies.

Repeated Risks in Dynamic Environments: What OSHA ITA Data Really Shows

OSHA’s 2024 Injury Tracking Application (ITA) data makes one thing clear: workplace injury patterns are not random. They reflect persistent, repeatable risks that surface in the same sectors, often under familiar conditions. Despite advancements in safety awareness, industrial operations continue to experience incidents tied to known exposures- especially where people, vehicles, and machinery operate in close proximity.

In today’s fast-paced, high-mix industrial settings, risk doesn’t appear overnight. It accumulates quietly:

- Blind spots and uncontrolled intersections in forklift-heavy areas remain common contributors to severe incidents.

- Pedestrian interactions in shared workspaces, especially when workflows shift rapidly, increase the likelihood of near misses.

- Overexertion, material handling, and powered industrial truck (PIT) events remain among the most frequently reported hazards across transportation, warehousing, and wholesale trade.

- Unsafe behaviors such as PPE non-compliance or route deviations are rarely one-time issues, but they repeat until seen and corrected.

- Congestion and layout changes driven by operational demands continue to outpace hazard re-evaluation and control implementation.

- Manufacturing, transportation/warehousing, and wholesale trade continue to report high incident volumes with flat year-over-year trends highlighting enduring exposures.

- Severity remains a key concern, with many incidents resulting in days away from work or restricted duty, particularly in material handling-intensive roles like forklift operators, stockers, and freight movers.

- OSHA enforcement is increasingly targeting high-hazard facilities based on submitted ITA data, especially where repeated case patterns indicate uncontrolled risks.

According to OSHA’s latest dataset:

In short, the data shows that:

The problem isn’t identifying what causes injuries. It’s recognizing when risk is forming early enough to act.

OSHA’s 2024 Injury Data: Stability That Signals Stagnation

The 2024 Injury Tracking Application (ITA) dataset, compiled from over 700,000 records, doesn’t show major shifts in total injury volume - but that’s not necessarily good news. According to OSHA’s expanded reporting structure and Ogletree Deakins’ analysis, this stability suggests that the same high-risk activities and environments are producing consistent injury outcomes year after year.

What the Data Reveals:

- Sector consistency: Four sectors continue to dominate recordable incident totals; manufacturing, transportation and warehousing, wholesale trade, and healthcare. Retail trade and construction also remain significant contributors, especially for severe outcomes.

- Severity, not just frequency, matters: Many reported cases resulted in days away from work (DAFW) or job transfer/restriction (DJTR). Sectors like transportation and healthcare showed double-digit median days lost per incident.

- Hazards are industry-specific, but familiar:

- Manufacturing: Machine guarding, energy control (LOTO), and chemical or noise exposure risks

- Warehousing/wholesale: PIT-related incidents, overexertion, and congested route hazards

- Retail: Slips, trips, falls, and stock handling injuries

- Construction: High-severity fall protection failures and struck-by/caught-in events

- High-risk roles: Laborers, stockers, forklift operators, truck drivers, and healthcare workers continue to appear most frequently in reported cases.

Why It Matters:

- The expanded case-level detail in 2024 reporting (including Form 300 and 301 data) now enables OSHA to more precisely target inspections, based not just on volume, but on how, where, and to whom incidents are happening.

- While headline totals may seem unchanged, the underlying exposure patterns are more visible than ever to regulators, unions, and potentially even litigation.

In summary:

The risks aren’t just persistent. They’re documented in sharper detail, making proactive risk management not just smart, but essential.

Turning OSHA Injury Data Into Preventive Safety Insight

OSHA’s ITA data shows where injuries are recorded, but it does not show when risk begins to develop. Most recordable incidents are preceded by near misses, blind spots, and unsafe behaviors that go unaddressed in real time.

Preventing repeat injuries requires visibility into these conditions as they emerge, not only after incidents occur. This is where advanced technologies can support safety teams by extending awareness and enabling earlier intervention.

How Trio Mobil Translates OSHA Risk Patterns Into Action

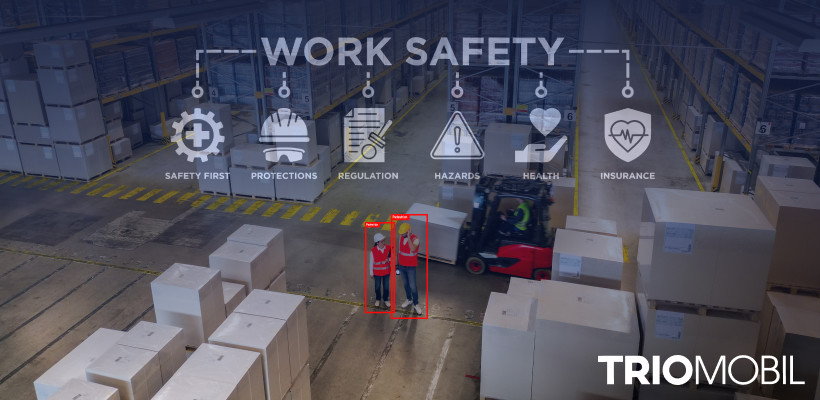

To break the cycle of repeat incidents highlighted in OSHA’s 2024 data, organizations need visibility into how risk forms during everyday operations. Trio Mobil’s AI and IoT-based safety systems provide that clarity for helping teams identify exposure early, understand where it repeats, and take action before it becomes a recordable incident.

The core solutions below will be explored in detail in the upcoming sector‑specific sections:

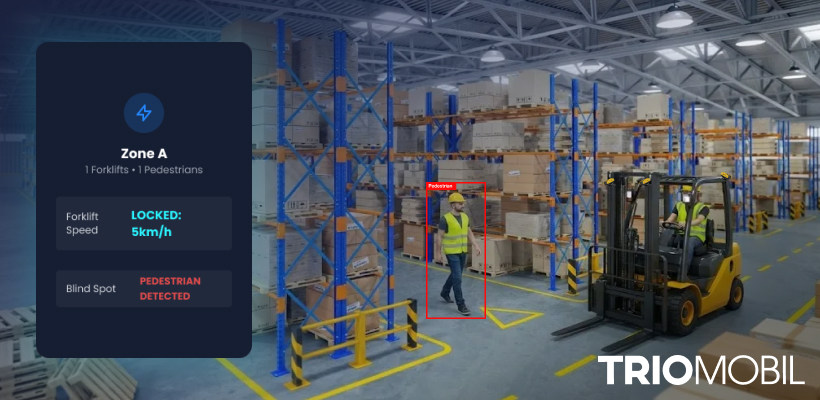

- Trio SAFE: 360° UWB-based proximity detection between forklifts and pedestrians. Visual and audible alerts, combined with zone-based speed control, reduce collision risk in congested or low-visibility areas.

- TRUE AI: AI-powered, tagless pedestrian detection for blind spots and machine zones. Issues alerts only when pedestrians are in actual danger, avoiding false alarms.

- AI Risk Radar: Tracks unsafe behaviors and repeated zone entries over time—such as PPE non-compliance or near-miss hotspots—to reveal persistent patterns and enable earlier intervention.

- FleetBridge: A centralized dashboard for multi-site safety visibility, near-miss tracking, and behavioral analytics. Supports consistent oversight and proactive response.

Manufacturing Industry Common Risks

Manufacturing environments continue to report incidents related to machine guarding, chemical and respiratory exposure, and hearing-related risks. In addition, unsafe behaviors such as PPE non-compliance, smoking in restricted areas, and mobile phone use near active machinery remain contributing factors.

These risks often emerge during routine operations, especially around high-speed machines, maintenance zones, and shared production areas where attention is divided and visibility is limited. Many incidents occur not because safeguards are absent, but because unsafe behaviors repeat unnoticed over time.

Enhancing Machine Zone Awareness With TRUE AI and AI Risk Radar

TRUE AI supports machine zone safety by continuously monitoring restricted and high-risk areas around equipment. It helps teams detect when unauthorized access occurs, when operators enter zones without appropriate PPE, or when unsafe behaviors take place near moving machinery.

AI Risk Radar adds a longer-term perspective by identifying recurring PPE non-compliance, repeated entry into hazardous zones, and behavior patterns that indicate elevated exposure. In several manufacturing customer deployments, this combination has helped safety teams move beyond isolated observations and focus on the specific machines, shifts, or zones where risk repeats most often.

By turning everyday behavior into actionable insight, these tools support preventive action before unsafe conditions lead to recordable incidents.

Wholesale Trade Industry Common Risks

Wholesale operations experience material handling injuries and powered industrial truck hazards similar to warehousing environments. Shared spaces between forklifts and pedestrians increase exposure, particularly in high-throughput facilities where picking, staging, and loading activities overlap.

Risk often concentrates around aisles, cross-traffic points, and temporary storage areas where forklift routes change frequently and pedestrian movement is less predictable. Near misses in these locations frequently precede recordable incidents.

Improving Forklift and Pedestrian Awareness With TRIO SAFE

TRIO SAFE supports forklift pedestrian risk monitoring by providing real-time awareness when forklifts and pedestrians enter close proximity. Alerts help draw attention in congested or blind areas, supporting safer movement without disrupting operational flow.

Centralized dashboards allow safety teams to review interaction patterns across multiple sites, identifying recurring hotspots and high-exposure workflows. In wholesale distribution customer environments, this visibility has supported data-driven layout adjustments, targeted signage, and operational changes focused on the most active interaction zones.

Rather than reacting to individual incidents, teams gain a clearer picture of where shared-space risk consistently forms.

Transportation and Warehousing Industry Common Risks

Material handling injuries and powered industrial truck-related events remain among the most common risks in transportation and warehousing. Congestion, route overlap, and limited visibility contribute to repeated exposure, particularly in loading docks, cross-docking zones, and high-volume picking areas.

Fast-paced operations increase the likelihood that near misses go unnoticed, allowing the same risk conditions to persist shift after shift.

Strengthening Movement Visibility With TRIO SAFE AI and FleetBridge

TRIO SAFE AI supports real-time awareness of forklift and pedestrian proximity, helping operators and nearby workers recognize risk as movement patterns change throughout the day. This is particularly valuable in dynamic dock areas and shared aisles where traffic density fluctuates.

FleetBridge complements this awareness by providing insight into forklift behavior, near misses, and repeated exposure patterns across operations. In transportation and warehousing customer deployments, this combination has helped safety teams understand how congestion forms, which routes create the most interaction, and where procedural or layout changes may reduce risk.

Together, these tools support a clearer understanding of daily movement dynamics and help teams address exposure patterns before incidents occur.

What the Data Signals for Employers

OSHA’s 2024 ITA data leaves little room for misinterpretation: workplace injuries are not decreasing but they’re repeating. The same sectors, job roles, and hazard types continue to drive the majority of incidents, reinforcing that most risks stem from predictable, operational patterns, not unexpected events.

For employers, this underscores a critical point:

What’s being reported to OSHA is not just injury data. It is a blueprint of unmanaged exposure.

Staying ahead of enforcement and protecting workers now requires:

- Earlier visibility into how and where risks are forming

- Real-time awareness in dynamic, shared environments

- Consistent, data-backed insights that guide proactive intervention

Organizations that align safety practices with these realities will not only reduce incident rates, but they’ll be better prepared for the scrutiny that comes with data-driven enforcement.

Aligning with OSHA Through Layered Safety: Trio Mobil’s Role in Risk Reduction

OSHA’s 2024 ITA data reveals a clear message:

Industrial risk is not decreasing. It is repeating.

To break this cycle, safety strategies must evolve from passive documentation to active prevention, built on layered systems that detect, respond to, and learn from everyday risk before it escalates into harm.

Key takeaways for the road ahead:

- The risks are known. Sector-specific hazards, like PIT incidents, overexertion, falls, and machine-related injuries, continue to drive incident volumes.

- The data is more detailed. With expanded case-level reporting (Forms 300/301), OSHA and other stakeholders have greater clarity on when, where, and how injuries occur.

- The expectation is higher. Regulators are using this data to inform inspections. Employers are expected to act on the patterns it reveals.

- The solution must be layered. A single tool isn’t enough. Prevention now requires multiple, connected systems that offer real-time insight, automated responses, and trend-level understanding.

Trio Mobil supports this next phase of industrial safety with a layered safety approach:

- Detecting unsafe interactions between pedestrians, forklifts, and machines in real time

- Monitoring behavioral patterns and identifying high-risk areas across shifts and sites

- Centralizing safety data for consistent oversight and informed decision-making

- Strengthening existing programs through modular, scalable safety layers

As regulatory visibility increases, so must organizational awareness. Preventing the next incident starts with seeing the next risk and addressing it through layered safety.

To explore how a layered safety approach can be applied in your facility using real-time data and OSHA-aligned strategies, reach out to the Trio Mobil team for a tailored consultation.

Disclaimer: Trio Mobil solutions are operator-assist aids. They do not replace safe working practices or prevent all incidents. Performance depends on operating conditions and configuration.

Product Catalogue 2026

Download our catalog and gain access to a wealth of information on how to enhance industrial safety and efficiency. Our latest catalog features a diverse range of products and services that can help you achieve your goals.

Learn more about Trio Mobil's Solutions

Fill out the form and we'll contact you!