Benefits for

Your Business?

Scope of the Solution

Trio Mobil Machine Efficiency Tracking solution enable to increase the productivity in the facility by providing visibililty to the performance of the machine.

What are the Capabilities?

- Real time monitoring of how long the machines work and their efficiency.

- Instantly measuring the performance of the machines through reports such as production, quantity, meter history.

- Providing early detection of machine breakdown and maintenance needs.

Who Can Use This?

All businesses in the manufacturing industry.

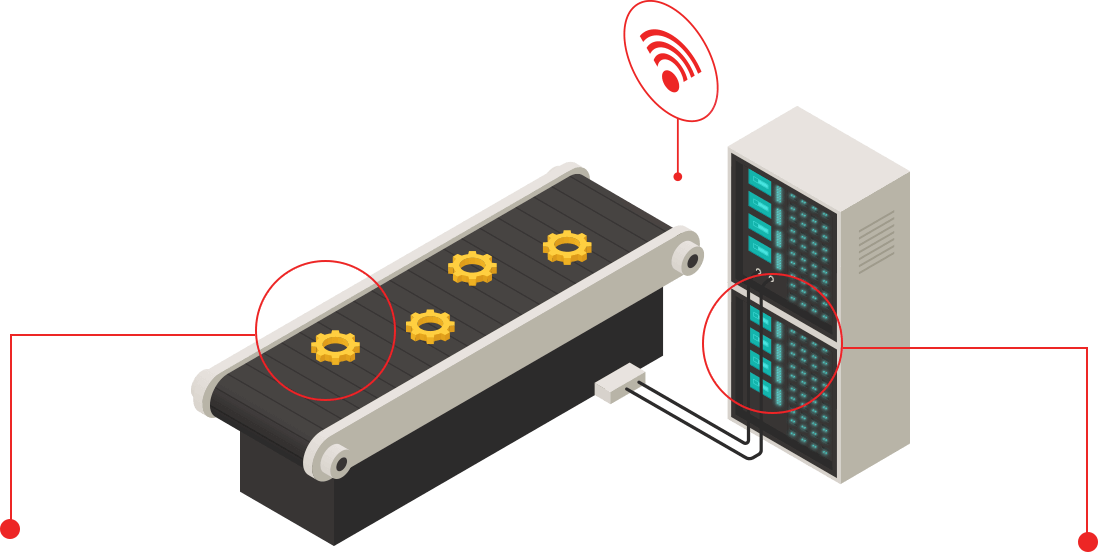

Production Line is Under Control 24/7 with Machine Efficiency Tracking System

Connect

Measure

Manage

More Efficient and Profitable Production Facilities with Trio Mobil IoT Technology

Production Quantities and Operational Time Tracking

+ You can monitor the production quantities and operational times digitally.

+ You can prevent production losses by being immediately notified of unexpected interruptions.

+ By monitoring the Overall Equipment Efficiency (OEE) instantly and historically, you can maximize your productivity.

+ By monitoring production processes in real time, you can prevent possible delays in the delivery date.

+ With shift-based efficiency analysis, you can ensure that all shifts work with the maximum efficiency.

+ You can monitor target achievement rates by setting targets for the production numbers on production line and machine basis.

Machine Energy Management and Predictive Maintenance

+ With machine and line-based energy consumption analysis, you can accurately determine your product-based costs.

+ By preventing machines, furnaces and other equipment from being operated outside of production time, you can reduce energy losses.

+ By monitoring the energy consumption, temperature and harmonic distortions of the machines, you can predict malfunctions and prevent unexpected production losses.

+ With the predictive maintenance feature, you can reduce waste rates by detecting problems early on that may affect production quality.

+ By determining the maintenance needs, you can extend the equipment life and get the maximum return from your investments.

+ By reducing your energy consumption, you can save money while creating a more environment friendly production process.